1 overview, 1 required adjustments – Epson 440 User Manual

Page 130

EPSON Stylus Color 440/640/740

Revision A

Chapter 5

Adjustment

130

5.1 Overview

This chapter describes adjustments required when the printer is

disassembled and assembled after repair.

5.1.1 Required Adjustments

Stylus Color 440/640/740 require the following adjustments. (Refer to

Table 5-1) Perform any necessary adjustment referring to the figures

and procedures described throughout this chapter.

Table below shows the actions taken and required adjustments in the

order to be performed.

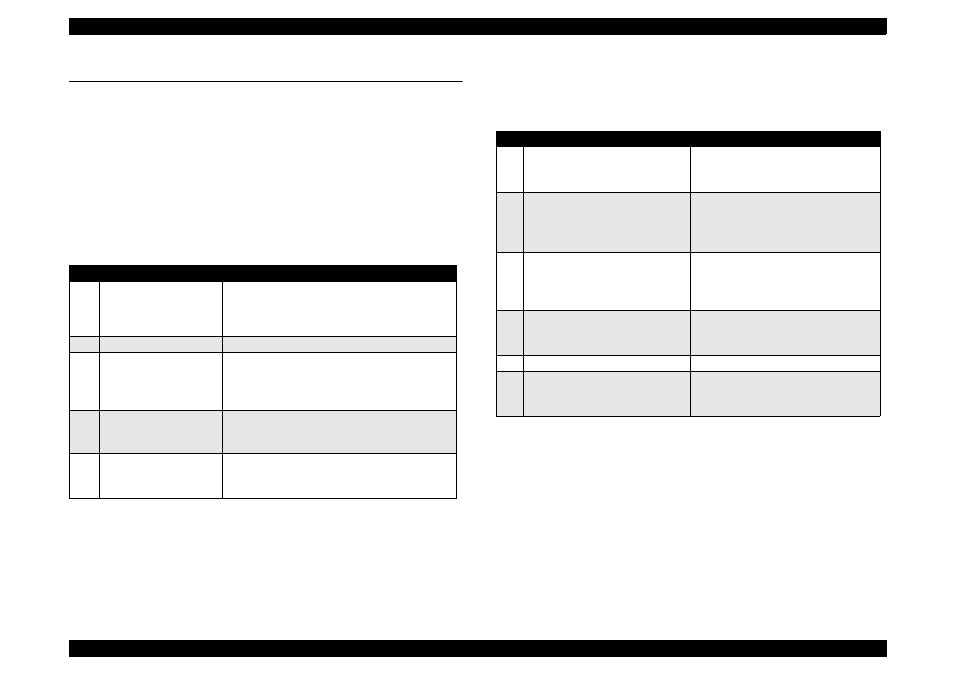

Table 5-1 Adjustment Required

No.

Adjustment Item

Conditions

1

Parallelism Adjustment

• When you replace or remove the Carriage

guide shaft.

• When you move the parallelism adjustment

bushing.

2

Initial Ink Charge

• When you replace or remove the printhead.

3

Head Voltage ID Input

• When you replace the printhead.

• When you replace the main board.

Note) The values stored in this address are not

erased by EEPROM reset operation.

4

Printing Head Angle

Adjustment

• When you replace or remove the printhead.

• When you move the printhead angle adjusting

lever.

5

Bi-D Adjustment

• When you replace or remove the printhead.

• When you replace the main board.

• When you replace the CR Motor.

Table 5-2 Actions Taken and Adjustment Required

No.

Content of Operation

Adjustment Procedure

1

Removal of the printhead

1. Perform initial ink charge.

2. Perform printhead angle adjustment.

3. Perform Bi-d Adjustment.

2

Replacement of the printhead

1. Perform Vh voltage writing operation.

2. Perform initial ink charge.

3. Perform printhead angle adjustment.

4. Perform Bi-d Adjustment.

3

Replacement of the main board

1. Perform Vh voltage writing operation.

2. Perform Bi-d adjustment.

3. Perform CG TAble setting (only for

Stylus Color 740)

4

Replacement or Removal of the

Carriage Unit

1. Perform parallel adjustment.

2. Perform printhead angle adjustment.

3. Perform Bi-d adjustment.

5

Replace of the CR Motor

1. Perform Bi-d adjustment.

6

Replacement of the Printer

Mechanism

1. Perform Head Voltage ID Input.

2. Perform initial ink charge.

3. Perform Bi-d adjustment.