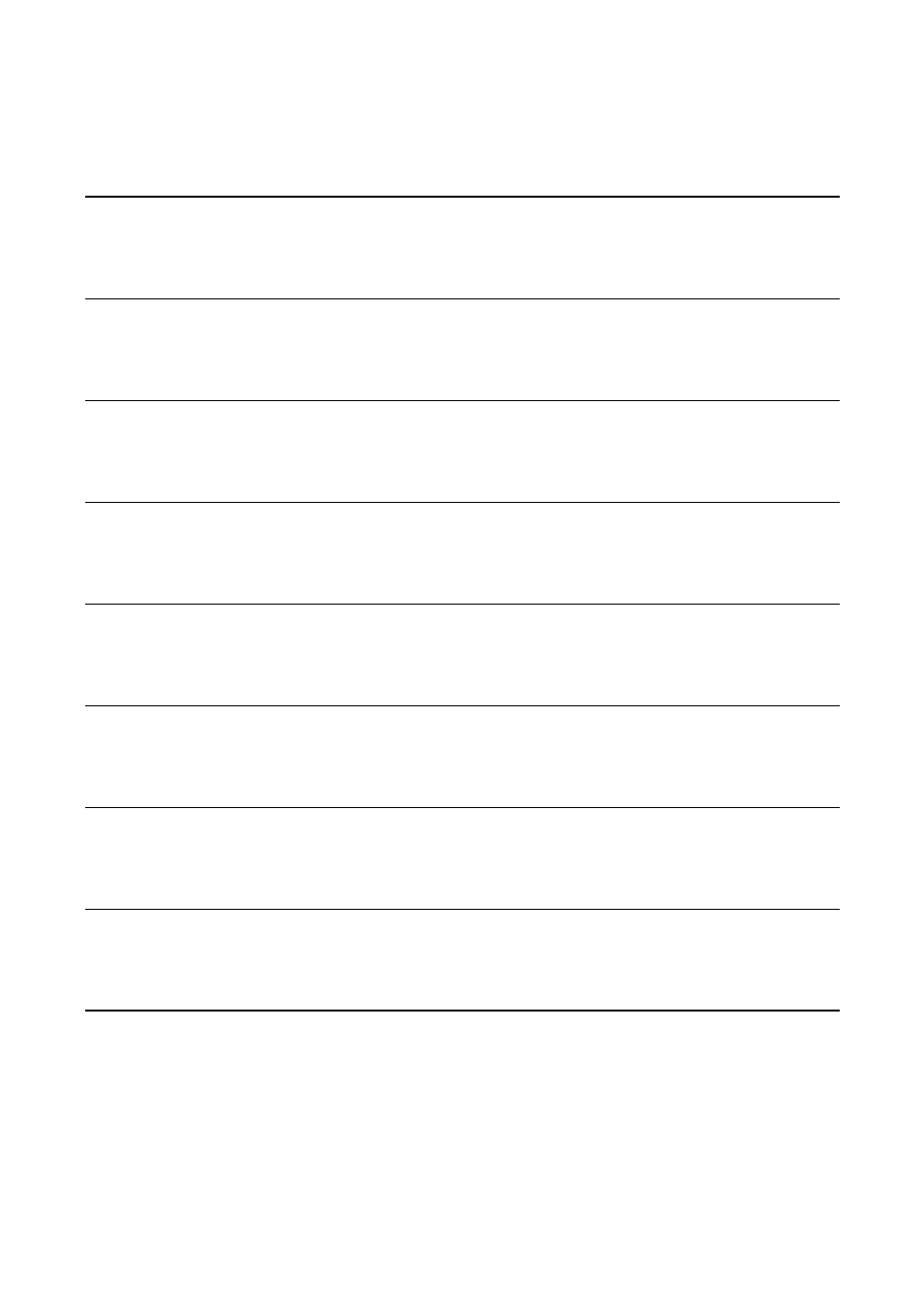

Table 7-2 summary of input assemblies continued – Emerson Process Management MICRO MOTION 2400S User Manual

Page 48

40

Micro Motion

®

Model 2400S Transmitters for DeviceNet

™

Using the Transmitter

• Status

• API temperature-corrected density

• API temperature-corrected volume flow

• API temperature-corrected volume inventory

• API average temperature-corrected density

• API average temperature

21

• BOOL

• REAL

• REAL

• REAL

• REAL

• REAL

Petroleum

measurement

application

• Status

• Mass flow

• Volume flow

• Temperature

• Enhanced density reference density

• Enhanced density specific gravity

21

• BOOL

• REAL

• REAL

• REAL

• REAL

• REAL

Enhanced

density

application

• Status

• Mass flow

• Volume flow

• Temperature

• Density

• Enhanced density concentration

21

• BOOL

• REAL

• REAL

• REAL

• REAL

• REAL

Enhanced

density

application

• Status

• Mass flow

• Volume flow

• Temperature

• Density

• Enhanced density Baume

21

• BOOL

• REAL

• REAL

• REAL

• REAL

• REAL

Enhanced

density

application

• Status

• Temperature

• Density

• Enhanced density net mass flow

• Enhanced density net mass total

• Enhanced density net mass inventory

21

• BOOL

• REAL

• REAL

• REAL

• REAL

• REAL

Enhanced

density

application

• Status

• Temperature

• Density

• Enhanced density net volume flow

• Enhanced density net volume total

• Enhanced density net volume inventory

21

• BOOL

• REAL

• REAL

• REAL

• REAL

• REAL

Enhanced

density

application

• Status

• Mass Flow

• Temperature

• Density

• Enhanced density reference density

• Enhanced density net mass flow

21

• BOOL

• REAL

• REAL

• REAL

• REAL

• REAL

Enhanced

density

application

• Status

• Volume flow

• Temperature

• Density

• Enhanced density reference density

• Enhanced density net volume flow

21

• BOOL

• REAL

• REAL

• REAL

• REAL

• REAL

Enhanced

density

application

Table 7-2

Summary of input assemblies continued

Instance ID

Data description

Size (bytes)

Data type

Description