3 how to characterize, How to characterize – Emerson Process Management MICRO MOTION 2400S User Manual

Page 35

Configuration and Use Manual

27

Required Transmitter Configuration

Requ

ired Co

nfi

g

u

ratio

n

Op

ti

on

al

Co

nfi

g

u

rati

o

n

Using the T

rans

m

itte

r

Us

ing a De

vice

Net T

o

ol

When configuring the flow calibration factor:

•

With ProLink II, enter the concatenated 10-character string exactly as shown, including the

decimal points. For example, using the Flow Cal value from Figure 6-1, enter

19.0005.13

.

•

With a DeviceNet tool, enter the two factors separately, i.e., enter a 6-character string and a

4-character string. Include the decimal point in both strings. For example, using the Flow Cal

value from Figure 6-1:

-

Enter

19.000

for the flow calibration factor.

-

Enter

5.13

for the temperature coefficient for flow.

6.2.3

How to characterize

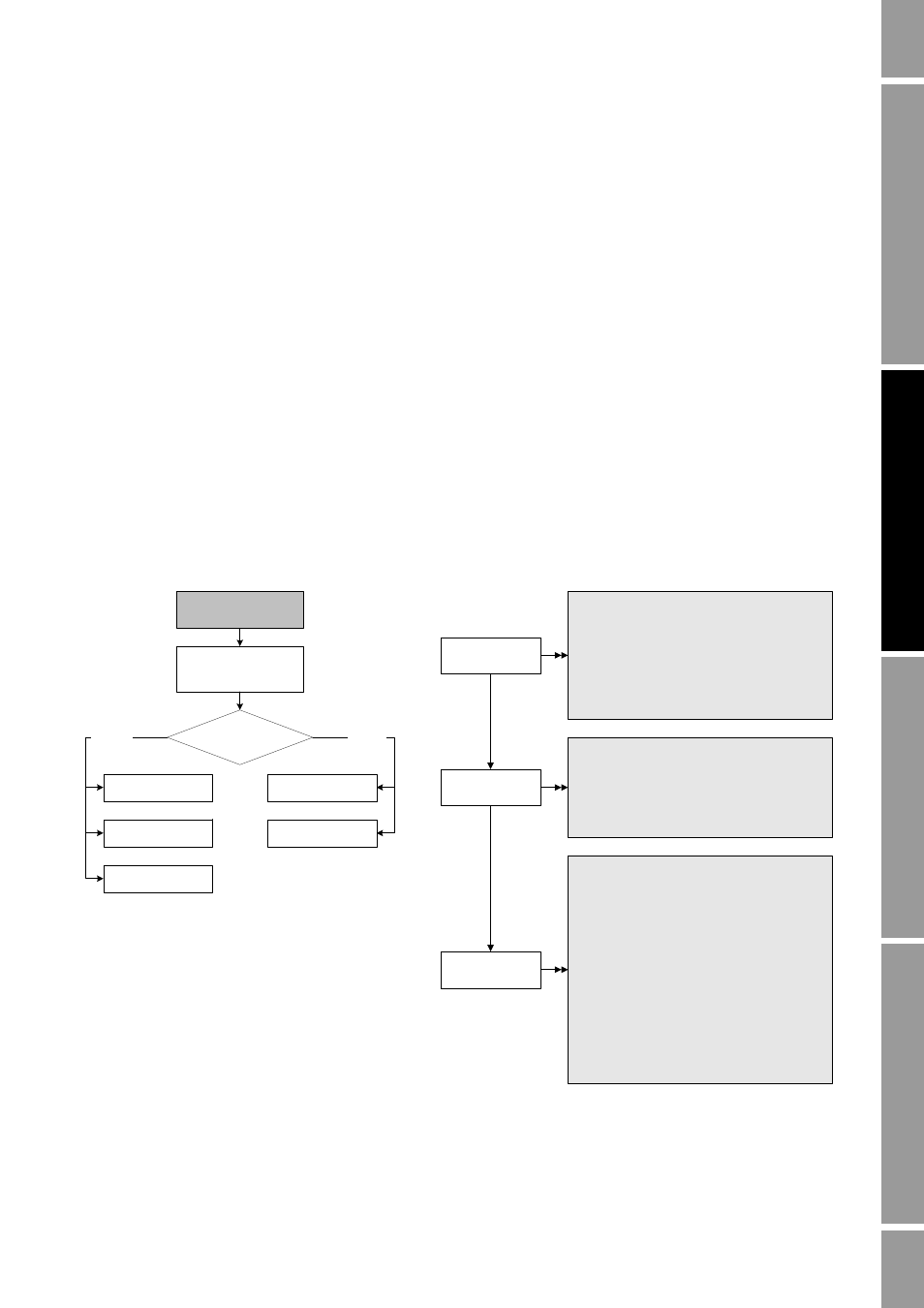

To characterize the flowmeter:

1. See the menu flowcharts in Figure 6-2.

2. Ensure that the correct sensor type is configured.

3. Set required parameters, as listed in Table 6-1.

Figure 6-2

Characterizing the flowmeter

Device

· Sensor type

Flow

T Series Config

Straight

tube

Curved

tube

Sensor type?

Density

Flow

Density

ProLink >

Configuration

Sensor type

Flow values

Class: Sensor Information Object (0x67)

Instance: 1

Attribute ID: 3

Data type: USINT

Value:

· 0: Curved tube

· 1: Straight tube

Service: Set

Density values

Class: Calibration Object (0x65)

Instance: 1

Attribute ID 7: K1

Attribute ID 8: K2

Attribute ID 9: FD

Attribute ID 12: D1

Attribute ID 13: D2

Attribute ID 17: DT

Attribute ID 18: FTG

Attribute ID 19: FFQ

Attribute ID 20: DTG

Attribute ID 21: DFQ1

Attribute ID 22: DFQ2

Data type: REAL

Service: Set

Class: Calibration Object (0x65)

Instance: 1

Attribute ID 1: Flow calibration factor

Attribute ID 2: Temperature coefficient for flow

Data type: REAL

Service: Set

DeviceNet tool

ProLink II