Ided in table 7-2. output – Emerson Process Management MICRO MOTION 2400S User Manual

Page 46

38

Micro Motion

®

Model 2400S Transmitters for DeviceNet

™

Using the Transmitter

API Object (0x69)

(1)

1

1

REAL

Temperature-corrected density

2

REAL

Temperature-corrected (standard) volume flow

3

REAL

Temperature-corrected (standard) volume total

4

REAL

Temperature-corrected (standard) volume

inventory

5

REAL

Batch weighted average density

6

REAL

Batch weighted average temperature

7

REAL

CTL

Enhanced Density

Object (0x6A)

(2)

1

1

REAL

Density at reference temperature

2

REAL

Density (fixed SG units)

3

REAL

Standard volume flow rate

4

REAL

Standard volume flow total

5

REAL

Standard volume flow inventory

6

REAL

Net mass flow rate

7

REAL

Net mass flow total

8

REAL

Net mass flow inventory

9

REAL

Net volume flow rate

10

REAL

Net volume flow total

11

REAL

Net volume flow inventory

12

REAL

Concentration

13

REAL

Density (fixed Baume units)

(1) Requires petroleum measurement application. See Section 8.13

(2) Requires enhanced density application. See Section 8.14.

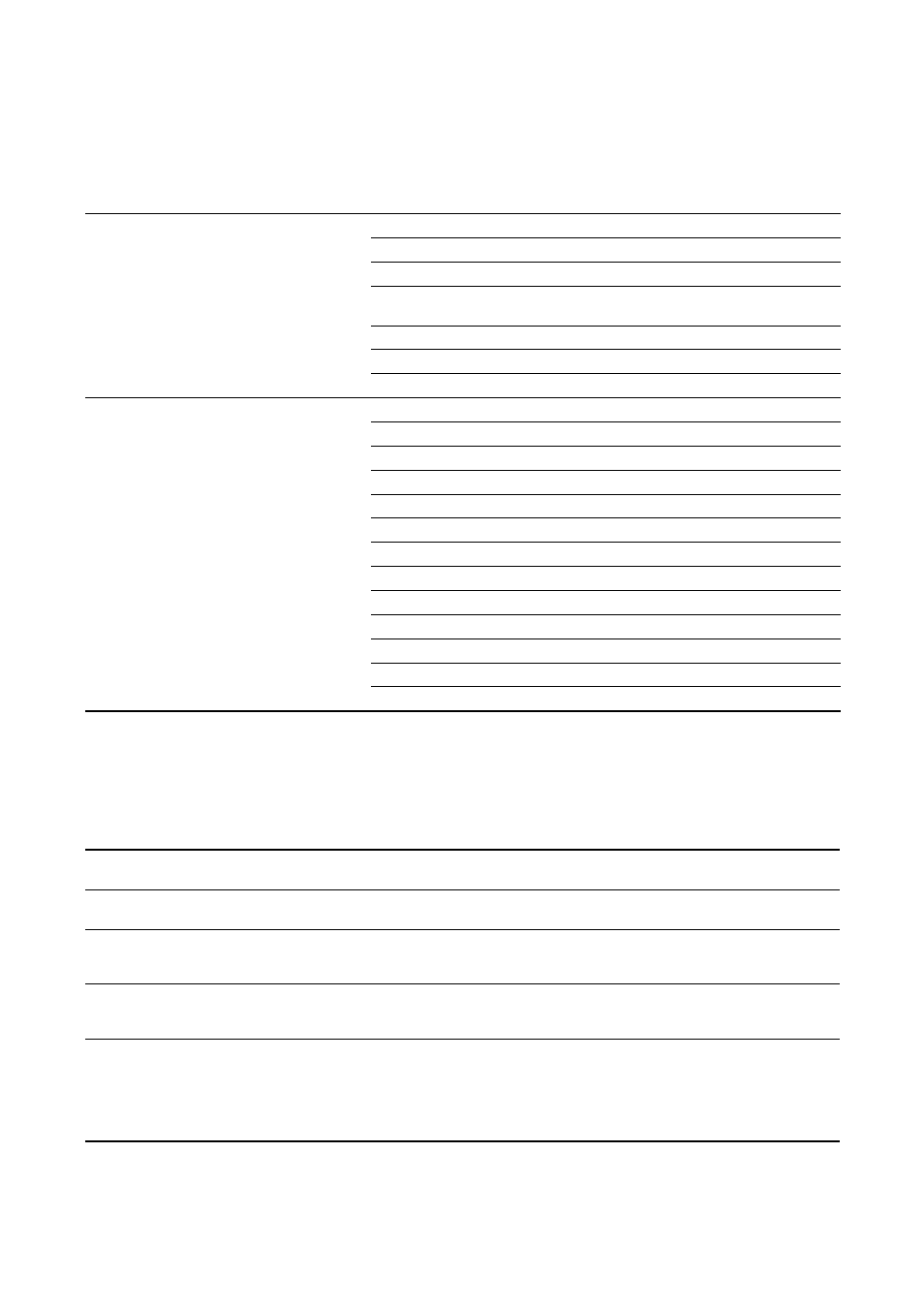

Table 7-2

Summary of input assemblies

Instance ID

Data description

Size (bytes)

Data type

Description

1

• Status

• Mass flow

5

• BOOL

• REAL

Mass flow

2

(1)

• Status

• Volume flow

5

• BOOL

• REAL

Volume flow

3

• Status

• Mass flow

• Mass total

9

• BOOL

• REAL

• REAL

Mass flow and

total

• Status

• Volume flow

• Volume total

9

• BOOL

• REAL

• REAL

Volume flow and

total

• Status

• Mass flow

• Temperature

• Density

• Volume flow

• Drive gain

21

• BOOL

• REAL

• REAL

• REAL

• REAL

• REAL

Basic process

variables

Table 7-1

Process data in DeviceNet objects continued

Class

Instance

Attribute

ID

Data

type

Description