Emerson Process Management MICRO MOTION 2400S User Manual

Page 128

120

Micro Motion

®

Model 2400S Transmitters for DeviceNet

™

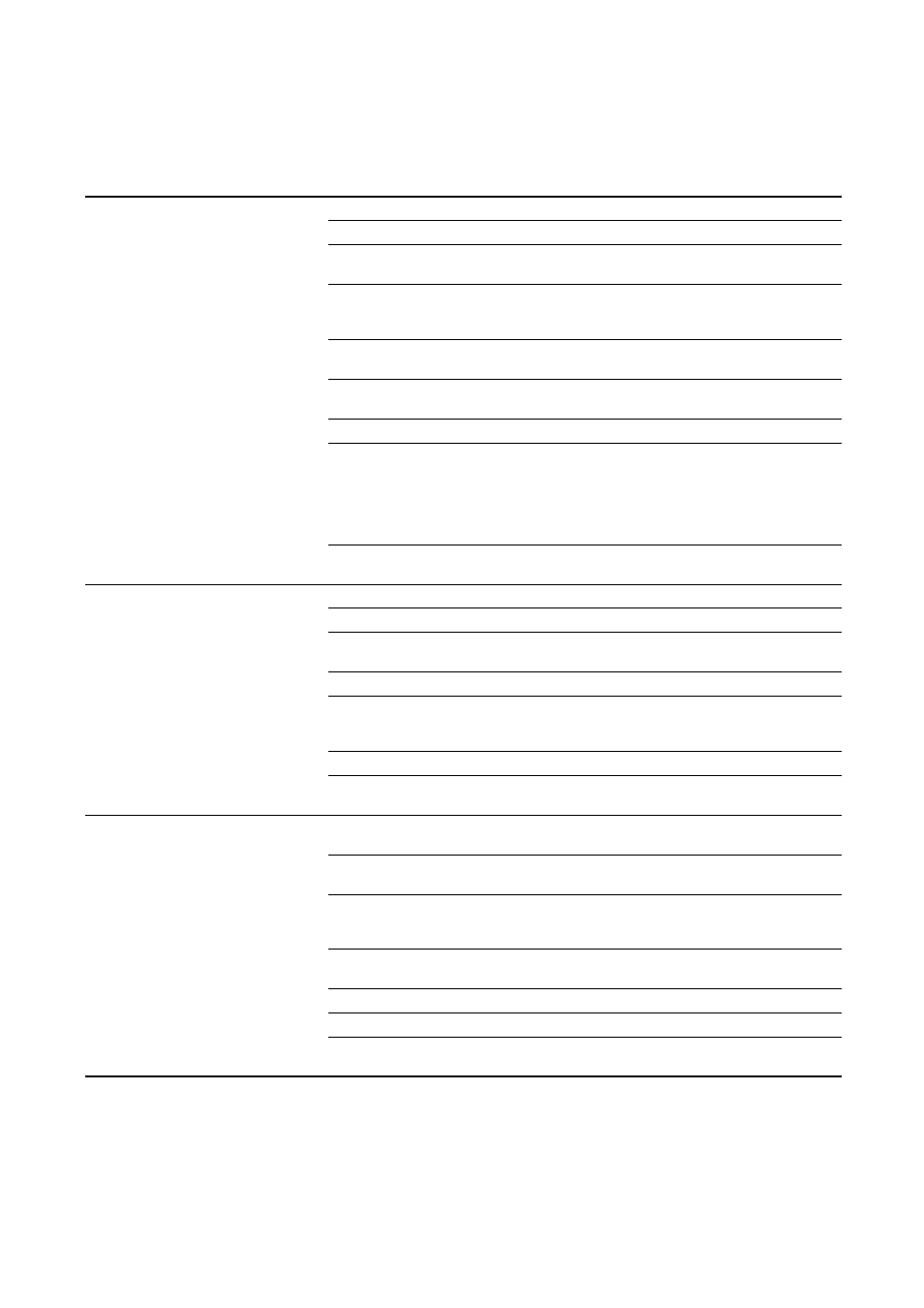

Troubleshooting

Erratic non-zero flow rate under

no-flow conditions

Leaking valve or seal

• Check pipeline.

Slug flow

• See Section 11.14.

Plugged flow tube

• Check drive gain and tube frequency.

Purge the flow tubes.

Incorrect sensor orientation

• Sensor orientation must be

appropriate to process fluid. See the

installation manual for your sensor.

Wiring problem

• Check the sensor circuitry. See

Vibration in pipeline at rate close to

sensor tube frequency

• Check environment and remove

source of vibration.

Damping value too low

• Check configuration. See Section 8.4.

Mounting stress on sensor

• Check sensor mounting. Ensure:

- Sensor is not being used to support

pipe.

- Sensor is not being used to correct

pipe misalignment.

- Sensor is not too heavy for pipe.

Sensor cross-talk

• Check environment for sensor with

similar (±0.5 Hz) tube frequency.

Erratic non-zero flow rate when flow

is steady

Slug flow

• See Section 11.14.

Damping value too low

• Check configuration. See Section 8.4.

Plugged flow tube

• Check drive gain and tube frequency.

Purge the flow tubes.

Excessive or erratic drive gain

• See Section 11.19.3

.

Output wiring problem

• Verify wiring between transmitter and

receiving device. See the installation

manual for your transmitter.

Problem with receiving device

• Test with another receiving device.

Wiring problem

• Check the sensor circuitry. See

Inaccurate flow rate or batch total

Bad flow calibration factor

• Verify characterization. See

Inappropriate measurement unit

• Check configuration. See

Bad sensor zero

• Rezero the flowmeter or restore the

factory zero or prior zero. See

Section 10.5.

Bad density calibration factors

• Verify characterization. See

Bad flowmeter grounding

• See Section 11.7.2.

Slug flow

• See Section 11.14.

Wiring problem

• Check the sensor circuitry. See

Table 11-3

Process variables problems and remedies continued

Symptom

Cause

Suggested remedy