KERN & SOHN AET 200-4NM User Manual

Operation manual analytical and precision balances, Kern aet,pet,ilt, Kern & sohn gmbh

KERN & Sohn GmbH

Ziegelei 1

D-72336 Balingen

E-Mail: [email protected]

Tel: +49-[0]7433- 9933-0

Fax: +49-[0]7433-9933-149

Internet: www.kern-sohn.com

Operation manual

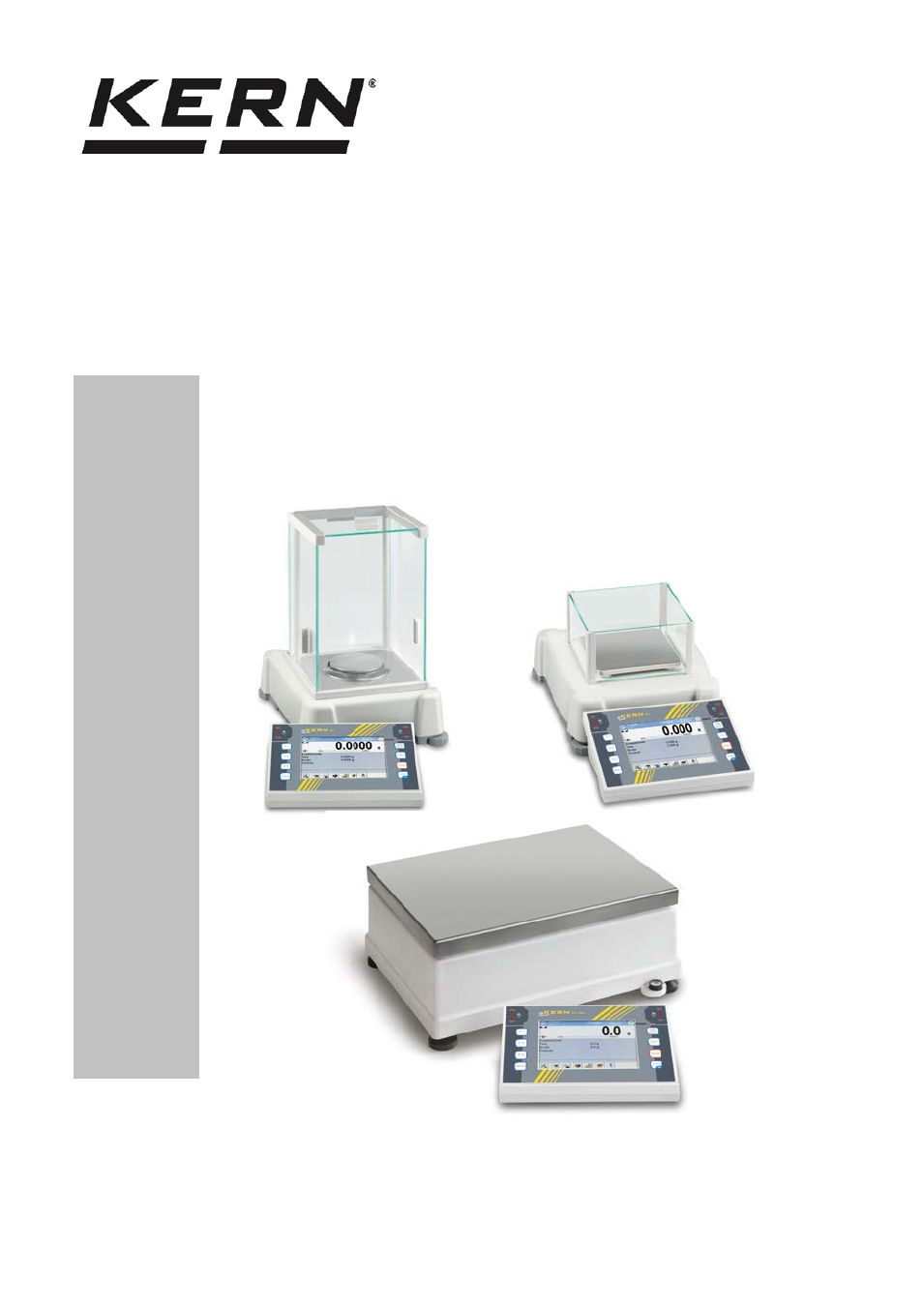

Analytical and precision balances

KERN AET,PET,ILT

Version 1.0

01/2014

GB

AET/PET/ILT-BA-e-1410

This manual is related to the following products:

Table of contents

Document Outline

- 1. BASIC INFORMATION

- 2. BALANCE DESIGN

- 3. STARTUP

- 4. BALANCE KEYBOARD – FUNCTION KEYS

- 5. SOFTWARE STRUCTURE

- 6. SOFTWARE WEIGHING WINDOW

- 7. LOGGING

- 8. MOVING IN USER MENU

- 9. WEIGHING

- 10. ADJUSTMENT

- 11. USERS

- 12. ACCESS LEVEL

- 13. PROFILES

- 14. WORKING MODES – general information

- 15. PARTS COUNTING

- 15.1. Additional settings of part counting mode

- 15.2. Parts counting – quick access keys

- 15.3. Setting standard (reference) mass by inserting determined part mass

- 15.4. Setting standard (reference) mass by weighing

- 15.5. Acquiring part mass from database

- 15.6. Updating part mass in the database

- 15.7. Part counting procedure

- 15.8. Checkweighing function in parts counting mode

- 15.9. Dosing function in parts counting mode

- 16. CHECKWEIGHING

- 17. DOSING

- 18. PERCENT SETUP

- 19. DENSITY

- 20. ANIMAL WEIGHING

- 21. FORMULATION

- 22. STATISTICS

- 23. PIPETTE CALIBRATION

- 24. DIFFERENTIAL WEIGHING

- 24.1. Additional settings of differential weighing mode

- 24.2. Differential weighing – quick access keys

- 24.3. Introducing a series to the Database of Series

- 24.4. An example of process for differential weighing mode

- 24.5. Copy tare

- 24.6. Using option “SAMPLE SELECTION”

- 24.7. Deleting a value

- 24.8. Printouts

- 25. STATISTICAL QUALITY CONTROL – SQC

- 25.1. Working mode activating procedure

- 25.2. Additional settings of the SQC mode

- 25.3. Carrying out a control process

- 25.4. Report from product control

- 27.1. Processes carried out on databases

- 27.2. Products

- 27.3. Weighing records

- 27.4. Clients

- 27.5. Formulation

- 27.6. Reports from formulation

- 27.7. Reports from density

- 27.8. Pipettes

- 27.9. Reports from pipette calibration processes

- 27.10. Series

- 27.11. A report from SQC

- 27.13. Ambient conditions

- 27.14. Packages

- 27.15. Warehouses

- 27.16. Printouts

- 27.17. Universal variables

- 27.18. Delete data older than

- 27.19. Export database of weighing records to file

- 28. COMMUNICATION

- 29. PERIPHERAL DEVICES

- 30. INPUTS / OUTPUTS

- 31. OTHERS

- 32. SYSTEM INFORMATION

- 33. COMMUNICATION PROTOCOL

- 34. CONNECTING PERIPHERAL DEVICES

- 35. DIAGRAMS OF CONNECTING CABLES

- 36. ERROR MESSAGES

- 37. APPENDIX A – Variables for printouts

- 38. APPENDIX G – Menu structure

- 39. Declaration of -Conformity