Benchmark 1.5ln dual-fuel low nox boiler, Gf-121 – AERCO BMK 1.5 LN Dual Fuel Feb 2013 User Manual

Page 94

CHAPTER 8: TROUBLESHOOTING GUIDE

Page

94 of 162 PR2: 05/09/12

Benchmark 1.5LN Dual-Fuel Low NOx Boiler

Operation and Maintenance Manual

OMM-0041_0C

GF-121

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526-0288

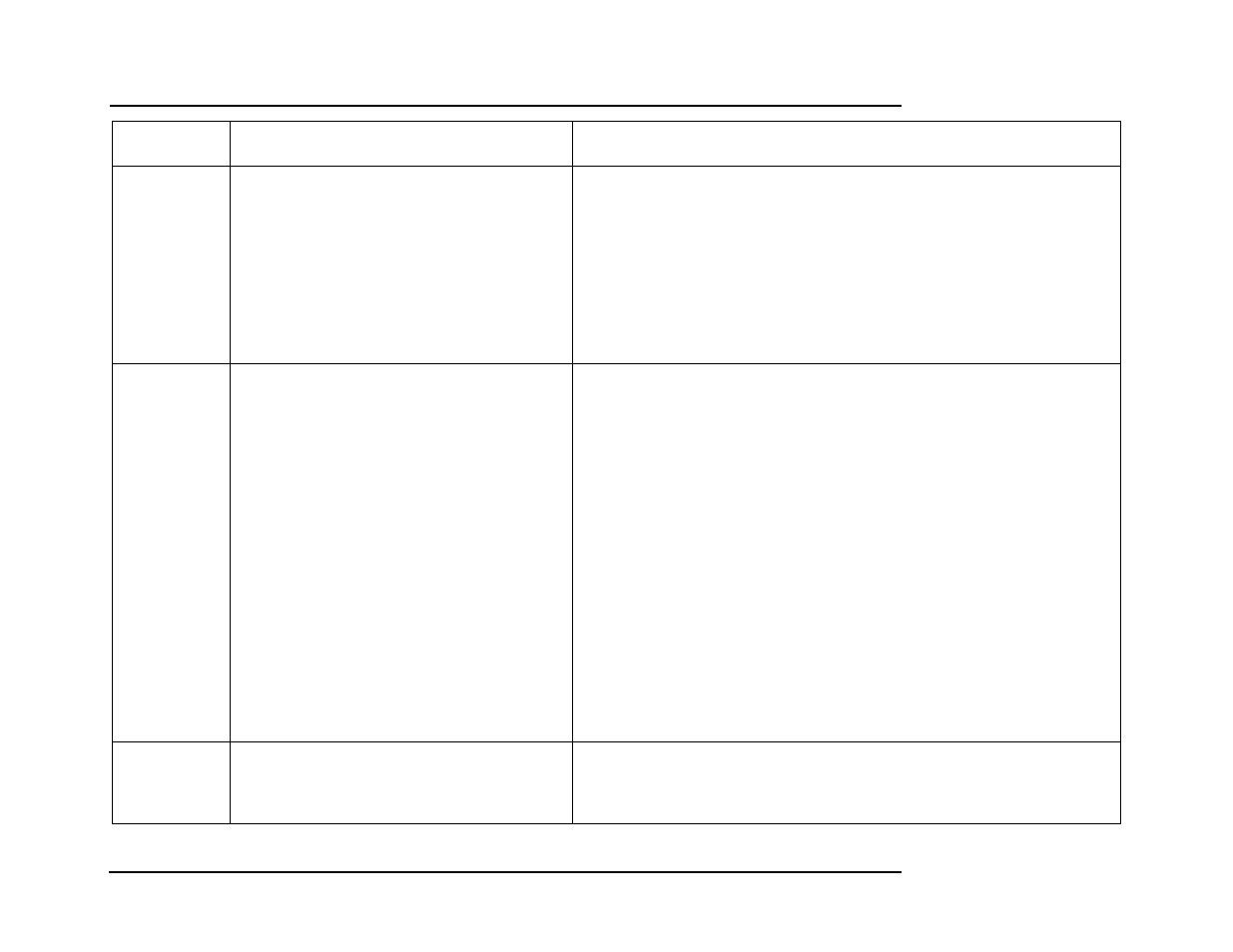

FAULT

INDICATION

PROBABLE CAUSES

CORRECTIVE ACTION

HIGH GAS

PRESSURE

1. Incorrect supply gas pressure.

2. Defective SSOV Actuator.

3. Defective High Gas Pressure Switch

4. Gas pressure snubber not installed.

1. Check to ensure gas pressure at inlet of SSOV is 2 psig maximum.

2. If gas supply pressure downstream of SSOV Actuator cannot be lowered,

to 1.5” W.C. using the gas pressure adjustment screw (see para. 4.3, step

10), the SSOV Actuator may be defective.

3. Remove the leads from the high gas pressure switch and measure

continuity across the common and normally closed terminals with the unit

not firing. Replace the switch if it does not show continuity.

4. See Figure 8-1. Ensure that the gas pressure snubber is installed at the

high gas pressure switch.

HIGH WATER

TEMP

SWITCH

OPEN

1. Faulty Water temperature switch.

2. Incorrect PID settings.

3. Faulty shell temperature sensor.

4. Unit in Manual mode

5. Unit setpoint is greater than Over

Temperature Switch setpoint.

6. Boiler Management System/AERCO Control

System PID or other settings not correctly

setup.

7. No interlock to boiler or BMS to disable

boiler(s) in event that system pumps have

failed.

8. System flow rate changes are occurring

faster than boilers can respond.

1. Test the temperature switch to insure it trips at its actual water

temperature setting.

2. Check PID settings against Menu Default settings in the Appendix. If the

settings have been changed, record the current readings then reset them

to the default values.

3. Using the resistance charts in the Appendix C, Measure the resistance of

Shell sensor and BTU sensor at a known water temperature.

4. If unit is in Manual Mode switch to Auto Mode.

5. Check setpoint of unit and setpoint of Temperature Switch; Ensure that the

temperature switch is set higher than the unit’s setpoint.

6. Check the BMS/ACS for changes to PID default values, correct as

necessary.

7. If system pump is controlled by Energy Management System other than

BMS/ACS or pumps are individually controlled by boiler, check to see if

there are flow switches interlocked to the BMS/ACS or boiler.

8. If the system is a variable flow system, monitor system flow changes to

ensure that the rate of flow change is not faster than what the boilers can

respond to.

HIGH WATER

TEMPERATU

RE

1. See HIGH WATER TEMPERATURE

SWITCH OPEN.

2. Temp HI Limit setting is too low.

1. See HIGH WATER TEMPERATURE SWITCH OPEN.

2. Check Temp HI Limit setting.

TABLE 8-1. BOILER TROUBLESHOOTING (Continued)