Benchmark 1.5ln dual-fuel low nox boiler, Gf-121 – AERCO BMK 1.5 LN Dual Fuel Feb 2013 User Manual

Page 53

CHAPTER 4: INITIAL START-UP

PR2: 05/09/12 Page

53 of 162

Benchmark 1.5LN Dual-Fuel Low NOx Boiler

Operation and Maintenance Manual

OMM-0041_0C

GF-121

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526-0288

8. Ensure that the Fuel Selector Switch (Figure 4-3) is in the PROPANE position.

9. Set the

ON/OFF switch to the ON position.

10. Access the control panel Configuration Menu and change the Max Valve Position to

70%. (Refer to Chapter 3, para. 3.3 for instructions on changing menu options).

11. Change the valve position to 29% using the ▲ arrow key. The unit should begin its

start sequence and fire.

12. Next, increase the valve position to 70%. Verify that the gas pressure downstream of

the Propane SSOV is 1” W.C. for both FM and IRI gas trains. If gas pressure

adjustment is required, refer to Figure 4-7 and remove the brass hex nut on the

Propane SSOV actuator containing the gas pressure regulator. (For IRI gas trains,

the regulator is on the downstream SSOV). Make gas regulator adjustments using a

flat-tip screwdriver to obtain 1” W.C.

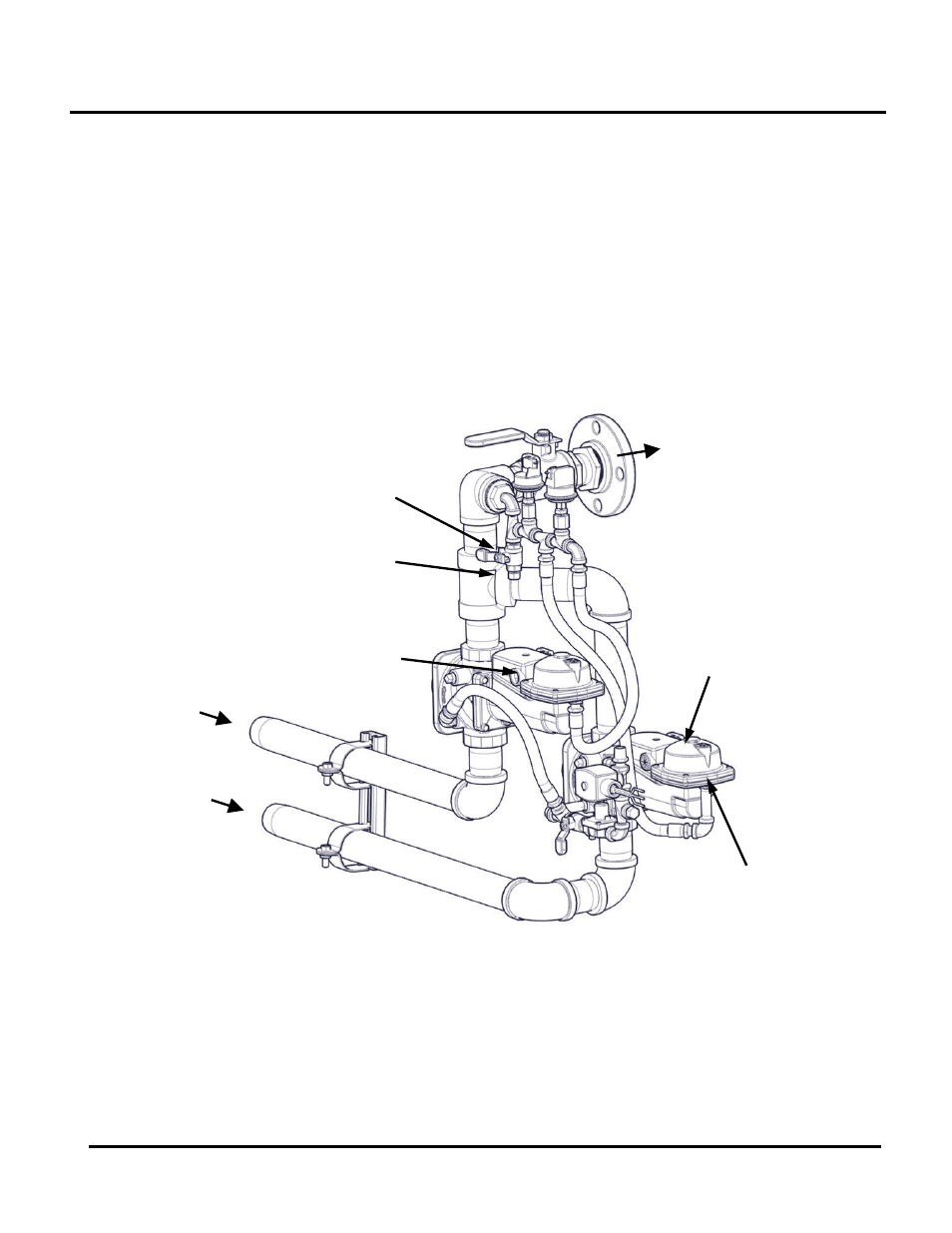

Figure 4-7: Manometer Installation Location for Combustion Calibration

13. With the valve position at 70%, insert the combustion analyzer probe into the vent

probe port opening (Figure 4-2) and allow enough time for the combustion analyzer

to settle.

14. Compare the measured oxygen % level to the range shown below. Also, ensure that

the carbon monoxide (CO) and nitrogen oxide (NOx) readings do not exceed the

values shown.

Combustion Oxygen Level at 70% Valve Position

NATURAL

GAS SSOV

PROPANE

GAS SSOV

NATURAL

GAS INLET

PROPANE

GAS INLET

TO AIR/FUEL

VALVE

1/4” NPT PLUG (Install

Combustion Calibration

manometer here)

LEAK DETECTION

BALL VALVE

BRASS HEX HEAD

CAP. REMOVE TO

ACCESS PRPPANE

GAS PRESSURE

ADJUSTMENT