Appendix e: mounting bolts and torque values, Introduction, Mounting bolts and torque – Rockwell Automation MPMA Integrated Multi-Axis Linear Stages User Manual

Page 127: Values, Mounting bolts and torque values, Appendix

Rockwell Automation Publication MPMA-UM001B-EN-P - November 2010

127

Appendix

E

Mounting Bolts and Torque Values

Introduction

This appendix provides typical torque values for standard and metric bolts.

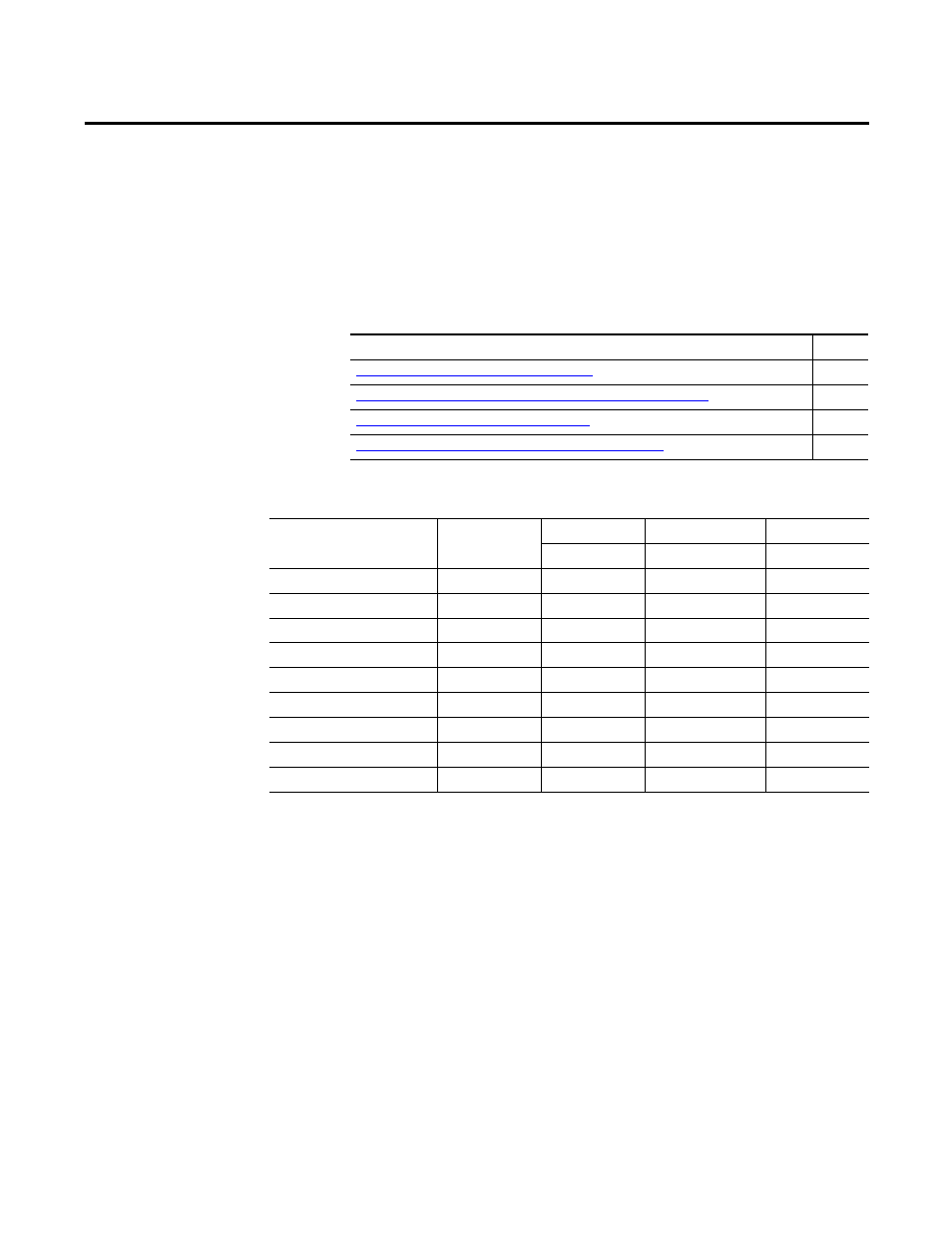

Table 59 - Recommended Seating Torque for Metric Bolts

Topic

Page

Recommended Seating Torque for Metric Bolts

127

Recommended Seating Torque for Mild Steel Rb 87 or Cast Iron Rb 83

128

Recommended Seating Torque for Brass Rb 72

129

Recommended Seating Torque for Aluminum Rb 72 (2024-T4)

130

Bolt Size (Metric)

(1)

Pitch

Plain

Cadmium Plated

Zinc

Nm (lb

•

in)

Nm (lb

•

in)

Nm (lb

•

in)

M1.6

(2)

0.35

0.29 (2.6)

0.22 (1.95)

0.41(3.64)

M2

(2)

0.40

0.60 (5.3)

0.45 (3.98)

0.84 (7.42)

M2.5

(2)

0.45

1.24 (11)

0.93 (8.25)

1.74 (15.4)

M3

0.5

2.15 (19)

1.61 (14.25)

3.00 (26.6)

M4

0.7

4.6 (41)

3.47 (30.75)

6.48 (57.4)

M5

0.8

9.6 (85)

7.20 (63.75)

13.4 (119)

M6

1.0

15.8 (140)

11.9 (105)

22.1 (196)

M8

1.25

39.5 (350)

29.7 (262.5)

55.4 (490)

M10

1.5

76.8 (680)

57.6 (510)

115.2 (1020)

(1) Mounting hardware is ISO 898/1 socket head cap bolt that meets or exceeds ANSI B113M, ISO 261, ISO 262 (coarse series only).

(2) Microsize bolt.