Power quality event indication, Configuring communication protocols, Configuring modbus – SATEC PM174 Manual User Manual

Page 98: Modbus point mapping

Chapter 4 PAS Application

Configuring Communication

98

Series PM174 Powermeters

4. Download your setup to the device.

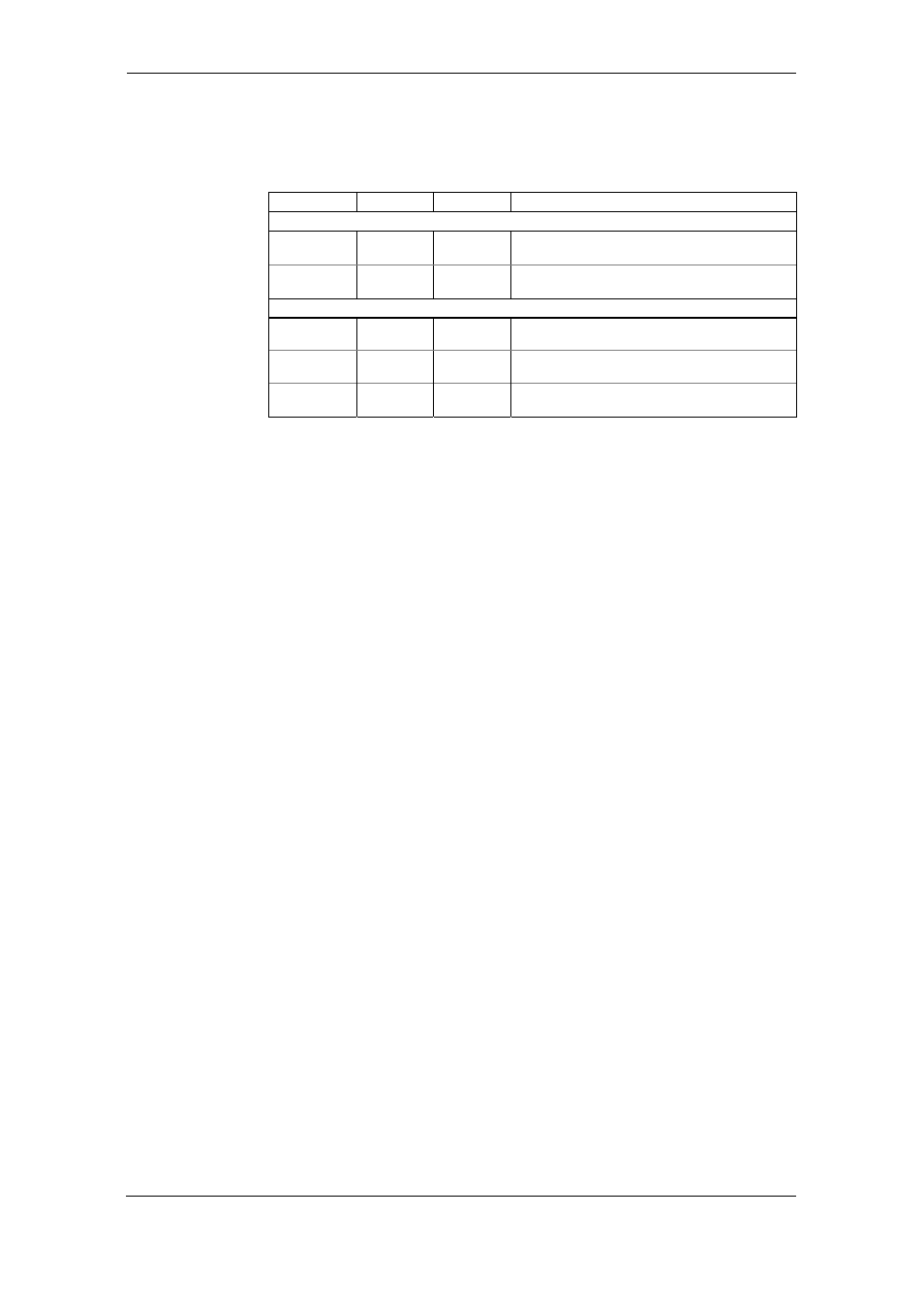

The available PQ recorder options are shown in the following

table. The picture above shows the default PQ recorder

settings.

Option Range

Default

Description

PQ Log Thresholds

Threshold, % 0-200.0%

Defines the operating threshold for the PQ trigger

in percent of the nominal (reference) value

Hysteresis, % 0-50.0%

5.0

Defines the hysteresis for the PQ trigger in

percent of the threshold

Waveform Log

On Start

Checked

Unchecked

Checked

Enables waveform log when the PQ event starts

On End

Checked

Unchecked

Unchecked Enables waveform log when the PQ event ends

Log No.

1-2

Specifies the waveform log file used for waveform

recording on the PQ event

The sag, swell and interruption triggers use the same

waveform log options. If you change one of them, the others

will be automatically adjusted to the same setting.

The waveform log option allows recording waveforms both at

the start and the end of a PQ event. Since the voltage

variations can last from some seconds to minutes, this allows

capturing and analyzing the voltage transitions using short

time waveform recording at the start and at the end of the

voltage sag or swell.

To enable or disable the PQ recorder:

1. Check or uncheck the Recorder

Enabled checkbox.

2. Send your setting to the device.

Power Quality Event Indication

When the PQ recorder detects a power quality fault, it

generates the specific internal event “PQ EVENT” that can be

monitored through a control setpoint. An event is asserted all

the time while the fault condition exists. The “PQ EVENT”

trigger is used to give a power quality fault indication via relay

contacts, or can be combined using the AND operator with

timer ticks for periodic data recording at the time of the fault to

produce voltage trending charts.

Configuring Communication Protocols

This section describes how to customize protocol options for

use with your application software.

Configuring Modbus

Modbus Point Mapping

The PM174 provides 120 user assignable registers in the

address range of 0 to 119. You can re-map any register

available in the meter to any assignable register so that

Modbus registers that reside at different locations may be

simply accessed using a single request by re-mapping them to

adjacent addresses.