Despatch P1400+ Temperature Controller User Manual

Page 94

88

Self-Tune

Type: Controller Tuning Definition

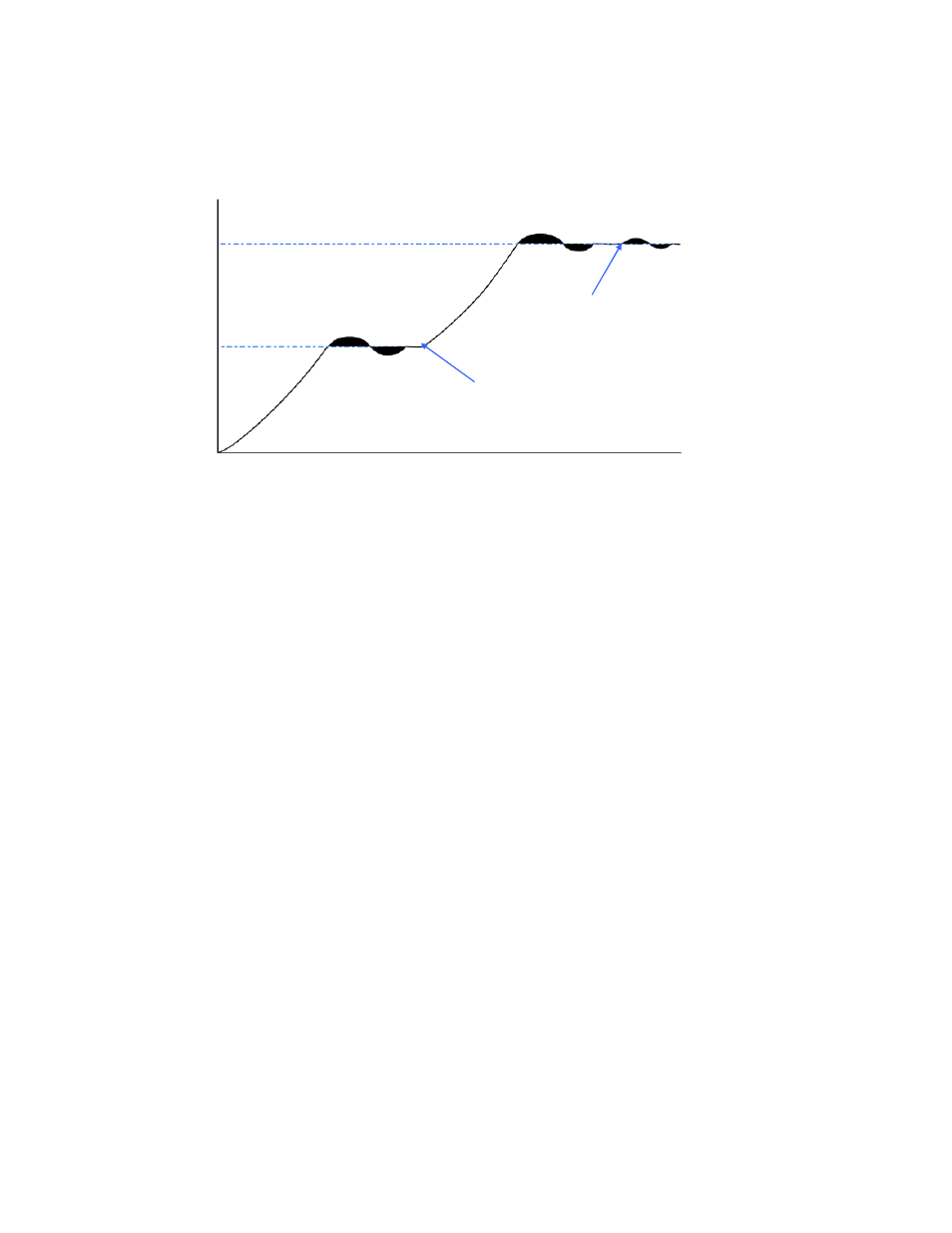

Self-Tune continuously optimises tuning while a controller is operating. It uses a pattern recognition

algorithm, which monitors the process error (deviation). The diagram shows a typical application

involving a process start up, setpoint change and load disturbance.

Figure 39. Self-Tune Operation

The deviation signal is shown shaded and overshoots have been exaggerated for clarity. The Self-

Tune algorithm observes one complete deviation oscillation before calculating a set of PID values.

Successive deviation oscillation causes values to be recalculated so that the controller rapidly

converges on optimal control. When the controller is switched off, the final PID terms remain stored

in the controller's non-volatile memory, and are used as starting values at the next switch on. The

stored values may not always be valid, if for instance the controller is brand new or the application

has been changed. In these cases the user can utilise Pre-Tune to establish new initial values.

Use of continuous self-tuning is not always appropriate for applications which are frequently

subjected to artificial load disturbances, for example where an oven door is likely to be frequently left

open for extended periods of time.

The Self-Tune feature on Valve Motor Drive controllers always sets the Rate parameter to zero

(OFF) because derivative action is not usually desirable in these applications.

Self-Tune cannot be engaged if a controller is set for On-Off Control.

Also refer to

Minimum Motor On Time

,

On-Off Control

,

Pre-Tune

,

PID

, and

Tuning

.

Serial Communications Option

Type: General Definition

An feature that allows other devices such as PC’s, PLC’s or a master controller to read or change an

instruments parameters via an RS485 Serial link. Full details can be found in the Serial

Communications sections of this manual.

Also refer to

Controller

,

Indicator

,

Master & Slave

,

Limit Controller

and

PLC

Set Valve Closed Position

Type: VMD Controller Parameter

When Valve Position Indication is to be used on Valve Motor Controllers, this parameter defines the

input value that will be measured by the Auxiliary Input, when the valve is fully closed. The valve

must driven to its “Closed” end stop before setting this parameter.

It must not be used to limit valve movement, separate Valve Close and Open Limit parameters are

available for this purpose.

Display code =

PcUL

, default setting = Auxiliary Input Range Minimum.

Also refer to

Auxiliary Input

,

Set Valve Opened Position

,

Valve Close Limit

,

Valve Open Limit

,

Valve Motor Control

and

Valve Position Indication

.

T

e

m

p

e

ra

tu

re

Setpoint 1

Setpoint Change

Load Disturbance

Time

Setpoint 2