Despatch P1400+ Temperature Controller User Manual

Page 80

74

Bias (Manual Reset)

Type: Controller Tuning Parameter

Used to manually bias the proportional output(s) to compensate for process load variations. Bias is

expressed as a percentage of output power and is adjustable in the range 0% to 100% (for Primary

Output alone) or -100% to +100% (for both Primary and Secondary Outputs). This parameter is not

applicable if the Primary output is set to ON/OFF control mode. If the process settles below setpoint

use a higher Bias value to remove the error, if the process variable settles above the setpoint use a

lower Bias value. Lower Bias values will also help to reduce overshoot at process start up.

Display code =

biAS

, default value = 25%.

Also refer to

ON/OFF Control

and

PID

.

Bumpless Transfer

Type: Controller Definition

A method used prevent sudden changes to the output power level when switching between

Automatic and Manual control modes. During a transition from Automatic to Manual, the initial

Manual Power value will be set to equal the previous automatic mode value. The operator can then

adjust the value as required. During a transition from Manual to Automatic, the initial Automatic

Power value will be set to equal the previous manual mode value. The correct power level will

gradually applied by the control algorithm at a rate dependant on the integral action resulting from

the Automatic Reset time. Since integral action is essential to Bumpless Transfer, this feature is not

available if Automatic Reset is turned off.

Also refer to

Automatic Rest

and

Manual Mode

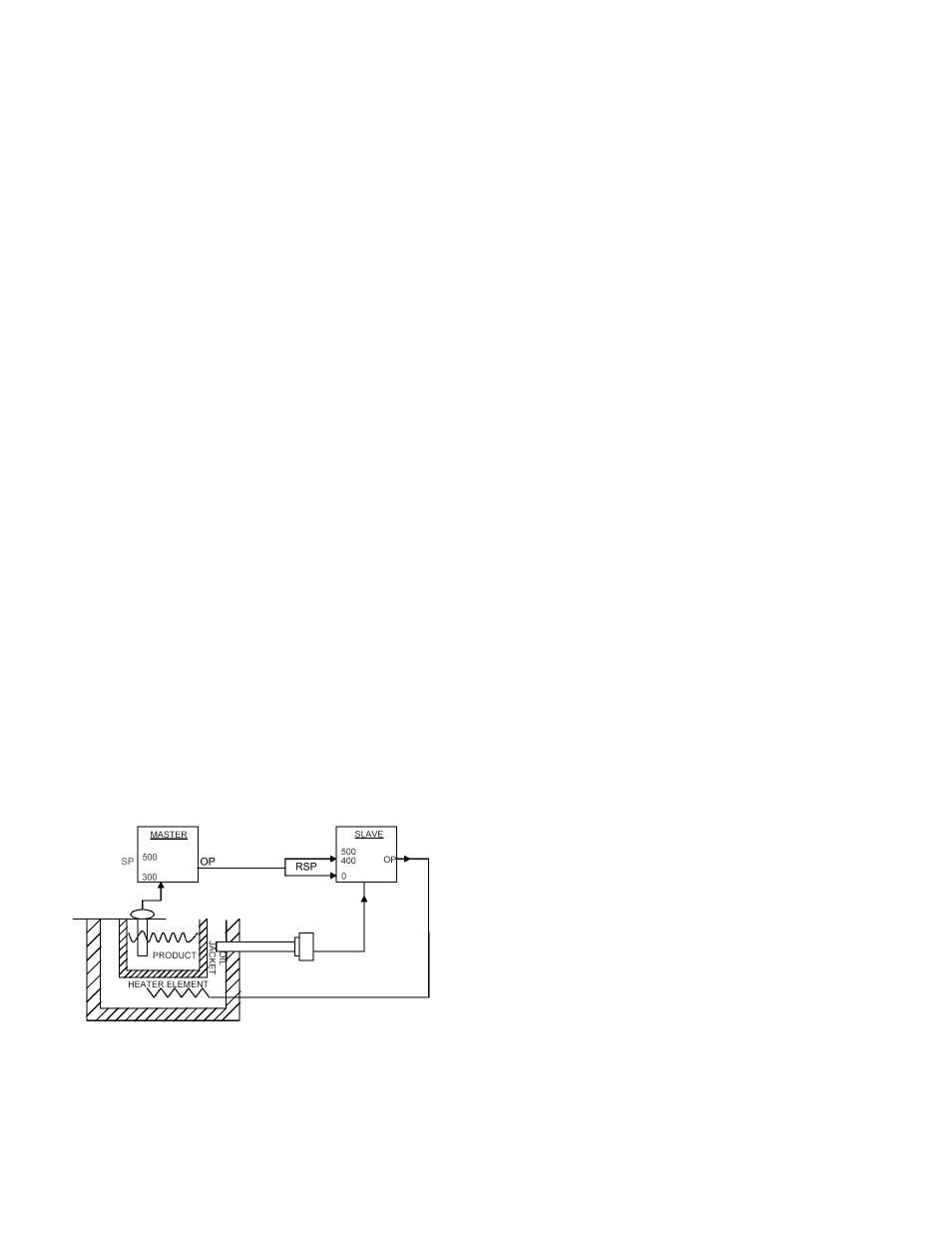

Cascade Control

Type: Controller Definition

Applications with two or more capacities (such as heated jackets) are inherently difficult for a single

instrument to control, due to large overshoots and unacceptable lags. The solution is to cascade two

or more controllers, each with its own input, in series forming a single regulating device. The product

setpoint temperature is set on the master controller. This is compared to the product temperature,

and the master’s PID output (mA or VDC) is fed into a remote setpoint input on the slave. The RSP

is scaled to suit any expected temperature. The slave loop’s natural response time should ideally be

at least 5 times faster than the master.

In the example, the maximum input represents 400ºC, thus restricting the jacket temperature. At

start-up the master compares the product temperature (ambient) to its setpoint (300ºC) and gives

maximum output. This sets the maximum (400ºC) setpoint on the slave, which is compared to the

jacket temperature (ambient) giving maximum heater output.

As the jacket temperature rises, the slave’s

heater output falls. The product temperature

also rises at a rate dependant on the transfer lag

between the jacket and product. This causes the

master’s PID output to decrease, reducing the

‘jacket’ setpoint on the slave, effectively

reducing the output to the heater. This continues

until the system becomes balanced.

When tuning a cascade system, first set the

master to manual mode. Tune the slave

controller using proportional control only (I & D

are not normally required) then return the master to automatic mode before tuning the master. The

result is quicker, smoother control with minimum overshoot and the ability to cope with load

changes, while keeping the jacket temperature within acceptable tolerances.

Also refer to

Manual Mode

,

Master & Slave

,

PID

,

Remote Setpoint

,

Remote Setpoint Lower Limit

,

Remote Setpoint Upper Limit

,

Setpoint

,

Setpoint Select

and

Tuning

.