2 option reduced bore type (/r1, /r2), 4 sizing, Option reduced bore type (/r1, /r2) -11 – Yokogawa digitalYEWFLO (DY) User Manual

Page 121: Measurable minimum fl ow velocity

<13. GENERAL SPECIFICATIONS>

13-11

IM 01F06A00-01EN

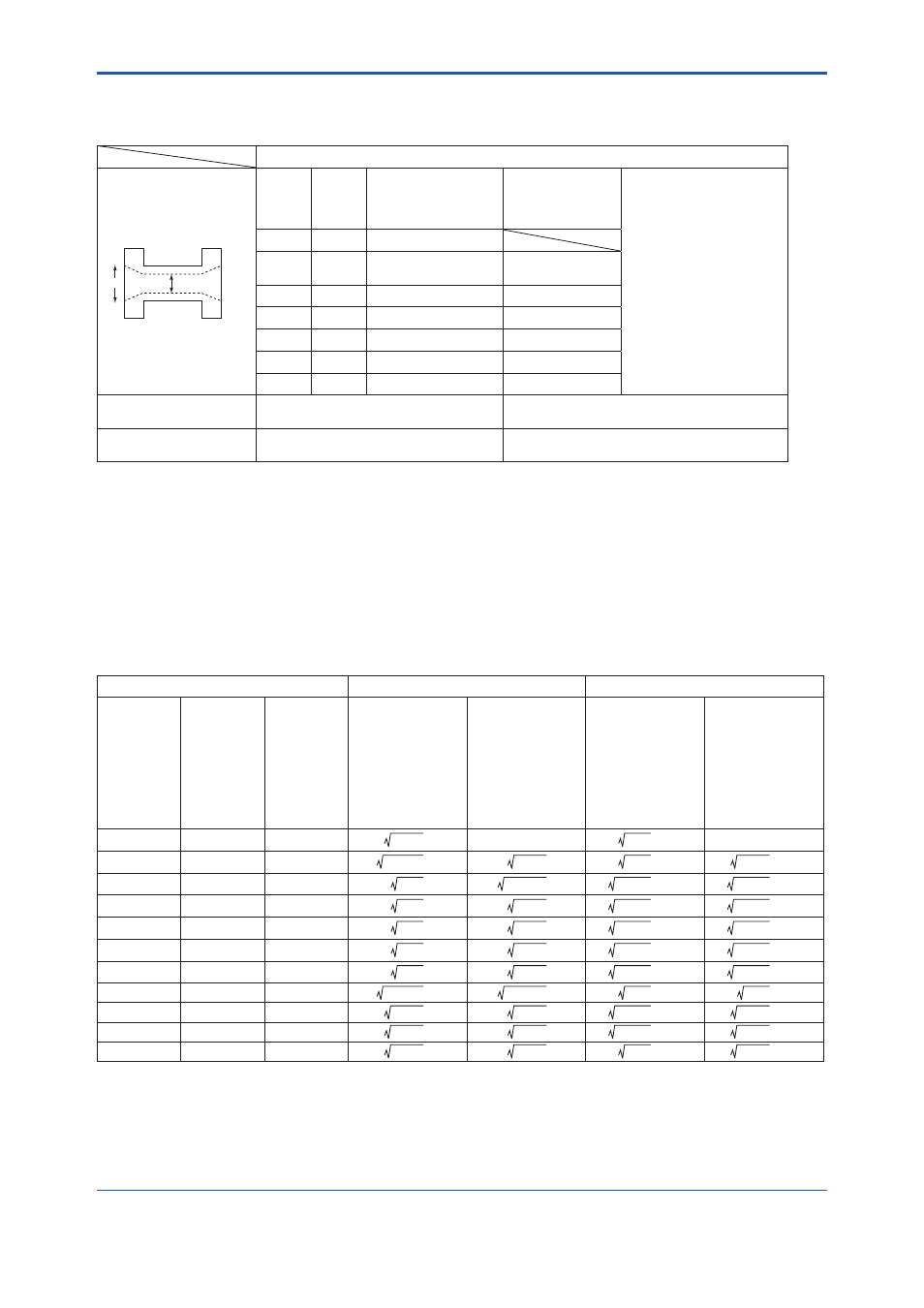

13.3.2 Option Reduced Bore Type (/R1, /R2)

This option is the same as standard specifi cation except the following items.

Reduced Bore Type (Option: /R1, /R2) (Note1)

(Note 2)

B

A

F1306.ai

Model

Code

Flange

piping

size

(A)

R1 Detector size

(inner dia.) (B)

R2 Detector size

(inner dia.) (B)

[Pressure Loss]

R1: about 15% increases to

standard type.

R2: about 28% increases to

standard type.

Refer to Section 13.5 “Detailed

Accuracy”

DY025

25mm

15 (14.6) (mm) (Note 3)

DY040

40mm

25 (25.7) (mm)

15 (14.6) (mm)

(Note 3)

DY050

50mm

40 (39.7) (mm)

25 (25.7) (mm)

DY080

80mm

50 (51.1) (mm)

40 (39.7) (mm)

DY100

100mm

80 (71) (mm)

50 (51.1) (mm)

DY150

150mm

100 (93.8) (mm)

80 (71) (mm)

DY200

200mm

150 (138.8) (mm)

100 (93.8) (mm)

Measurable minimum

fl ow velocity

Liquid, Gas, Steam

Refer to Table 13.5.

Range of measurable

fl ow velocity

Liquid, Gas, Steam

Refer to Table 13.6.

(Note 1) For accuracy, refer to Section 13.5 “Detailed Accuracy”. Cryogenic Version /LT and SAA Intrinsically safe /SS1 are not available.

(Note 2) Flange type only: JIS10K, 20K (BJ1, BJ2) and ANSI150, 300 (BA1, BA2, BS1, BS2)

(Note 3) High process temperature version /HT and Multi-variable type /MV for DY025/R1 and DY040/R2 are not available.

13.4 Sizing

The following items are the basic specifi cations.

In case of the defi nite sizing, it is neccessary to check by the sizing software.

Measurable minimum fl ow velocity

Table 13.5

Relationship between Minimum Velocity and Density

Model Code

Liquid

Gas, Steam (Note1)

Standard

Type,

Multi-Variable

Type(/MV)

Reduced

Bore Type

(/R1) (Note2)

Reduced

Bore Type

(/R2) (Note2)

Standard Type,

Cryogenic Version

(/LT)(Note2),

Multi-Variable Type

(/MV)

Unit: m/s

High Process

Temperature

Version(/HT),

High Process

Temperature

Version Multi-

Variable Type

(/HT/MV)

Unit: m/s

Standard Type,

Cryogenic Version

(/LT)(Note2),

Multi-Variable Type

(/MV)

Unit: m/s

High Process

Temperature

Version(/HT),

High Process

Temperature

Version Multi-

Variable Type

(/HT/MV)

Unit: m/s

DY015

DY025/R1

DY040/R2

250/

ρ

—

80/

ρ or 3

—

DY025

DY040/R1

DY050/R2

122.5/

ρ

490/

ρ

45/

ρ or 2

125/

ρ or 2

DY040

DY050/R1

DY080/R2

90/

ρ

302.5/

ρ

31.3/

ρ or 2

90.3/

ρ or 2

DY050

DY080/R1

DY100/R2

90/

ρ

160/

ρ

31.3/

ρ or 2

61.3/

ρ or 2

DY080

DY100/R1

DY150/R2

90/

ρ

160/

ρ

31.3/

ρ or 2

61.3/

ρ or 2

DY100

DY150/R1

DY200/R2

90/

ρ

160/

ρ

31.3/

ρ or 2

61.3/

ρ or 2

DY150

DY200/R1

—

90/

ρ

160/

ρ

31.3/

ρ or 3

61.3/

ρ or 3

DY200

—

—

122.5/

ρ

202.5/

ρ

45/

ρ or 3

80/

ρ or 3

DY250

—

—

160/

ρ

360/

ρ

61.3/

ρ or 3

125/

ρ or 3

DY300

—

—

160/

ρ

360/

ρ

61.3/

ρ or 3

125/

ρ or 3

DY400

—

—

250/

ρ

490/

ρ

80/

ρ or 4

125/

ρ or 4

ρ: Density at operating conditions (kg/m

3

), Liquid density range is 400 to 2000 kg/cm

3

(Note1) The case of gas, it is whichever is greater than a fi xed value of each model and calculated from density.

(Note2) Reduced bore type /R1 or /R2 are not available to combine for Cryogenic Version /LT.