3 option specifications, 3 option, Specifi cations -8 – Yokogawa digitalYEWFLO (DY) User Manual

Page 118: 3 option specifi cations, General specifications

<13. GENERAL SPECIFICATIONS>

13-8

IM 01F06A00-01EN

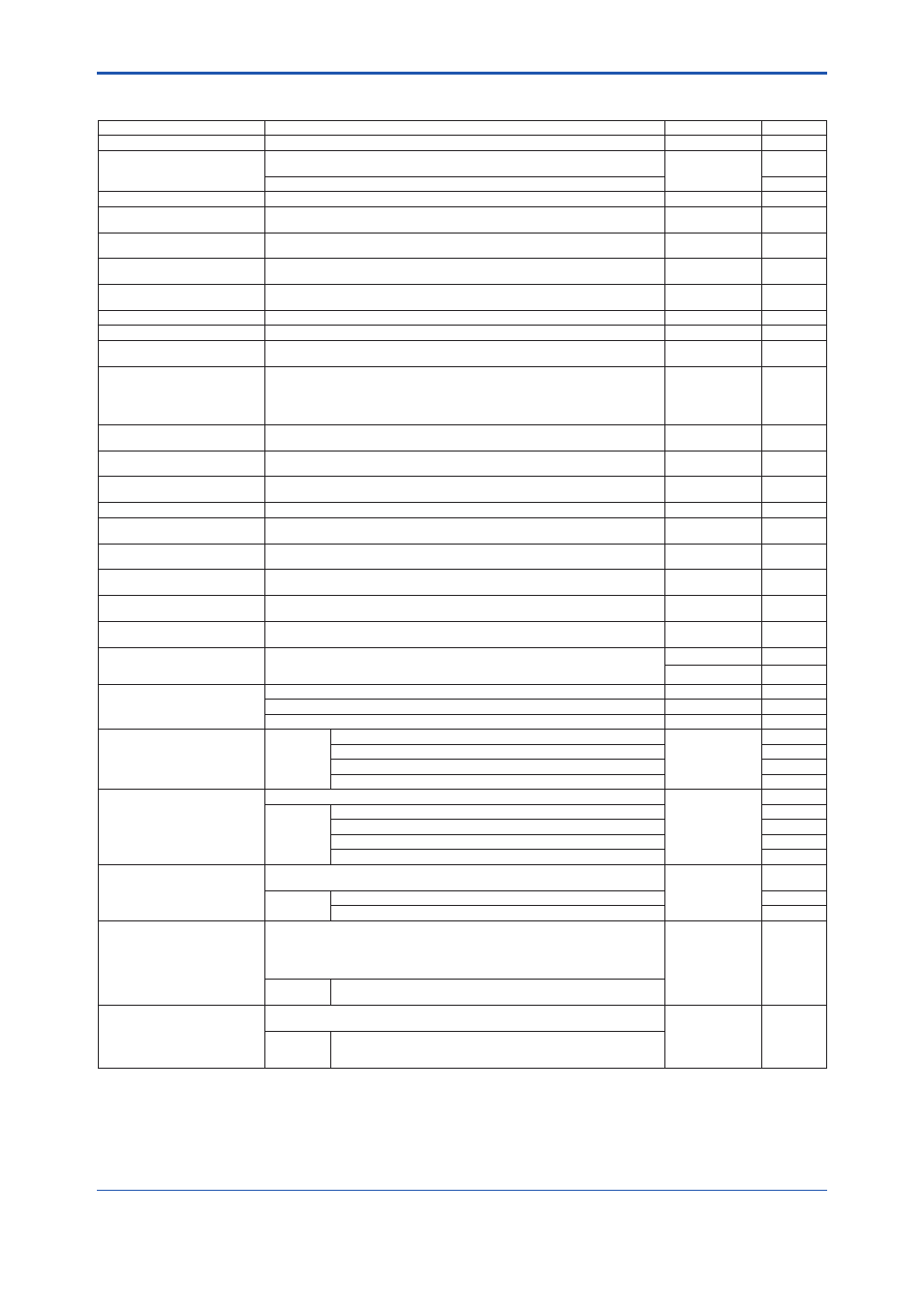

13.3 Option Specifi cations

Item

Specifi cation

Applicable Model

Code

Multi-Variable Type (Note 5)

Build in Temperature sensor (Pt 1000 ) in vortex shedder bar.

DY / DYA

MV

Reduced bore type (Note 8) (Note 12)

Integrated and welded construction with concentric reduced bore piping.

R1: Detector size (B) is one meter body size down of digitalYEWFLO to fl ange pipe size (A).

DY

R1

R2: Detector size (B) is two meter body size down of digitalYEWFLO to fl ange pipe size (A).

R2

Stainless Steel Tag Plate (Note 1)

JIS SUS304 tag plate, hung on the case.

DY / DYA

SCT

Stainless Steel Bolt & Nut Assembly

JIS SUS304 bolt/nut assembly.

Used when a wafer type is installed.

DY Wafer Type

BL

Paint Color Change

Only for the covers: Refer to Table 13.3

DY / DYA

Refer to

Table 13.3

Hydrostatic / Pneumatic Test Certifi cate

Test pressure value is in accordance with Table 13.4 Test time: 10 minutes. Available for the

Standard type. Test medium: Air, Nitrogen or Water.

DY

T01

(Note 11)

Hydrostatic Test Certifi cate

Test pressure value is in accordance with Table 13.4 Test time: 10 minutes. Available for the

Standard type. Test medium: Water.

DY

T02

(Note 11)

Degrease Treatment (Note 2)

Degrease cleansing treatment.

DY

K1

Epoxy Coating

Epoxy coating for case and cover.

DY / DYA

X1

Pilling up coating to keep off corrosion

Epoxy and Polyurethane coating for the purpose of corrosion - proof improvement; salt damage,

alkali, climate and acidity

DY / DYA

X2

High Process Temperature Version

This specifi cation temperature is from -29 to +450 °C

Refer to Table 13.1, Figure 13.4.

Refer to Table 13.5 for minimum velocity.

Refer to Note 5 for the combination of High Process Temperature Version (/HT) and Multi-Variable

Type (/MV).

DY***-N

HT

Cryogenic Version (Note 7)

This specifi cation temperature is from -196 to +100 °C

Refer to Table 13.1, Figure 13.5. /R1 and /R2 are not available.

DY***-N

LT

Stainless Steel Bracket for Remote

Conveter (DYA)

The bracket material for remote converter type (DYA) is JIS SUS304.

DYA

SB

Lightning Protector

There is an arrester inside converter for power supply line.

Maximum power supply voltage: 30VDC

DY Integral Type

/ DYA

A

NACE Material (Note 10)

Refer to Table 13.1.

DY

NC

Compliance with NAMUR (Note 6)

Compliance with NAMUR43. Current signal for measurement is 4mA up to 20.5mA. Set output

3.6mA or less when burn-out occurred.

DY / DYA

NM

Anti-corrosion Version II

Anti-corrosion Version II. Refer to Table 13.1. DY150/R1, DY150/R2, and DY200/R2 are not

available.

DY

HY

Converter Installing Direction 180°

Change (Note4)

Converter installing direction 180° change inversely when shipped.

DY

CRC

Down-scale burn-out in CPU or

EEPROM failure (Note 3)

Set output 3.6mA or less when burn-out occurred.

DY Integral Type

/ DYA

C1

Stainless steel housing (Note 9)

Converter housing, case and cover material: JIS SCS14A or ASTM, ASME CF8M stainless steel

castings. (equivalent to JIS SUS316)

DY***-N / DYA

E1

Flameproof Packing Adapter

Power source connection port and signal cable (remote type) connection port. JIS G1/2 female

thread. Other cable shape: ø 8 to ø 12.

/G11: One piece, /G12: Two pieces.

DY / JF3

G11

DYA / JF3

G12

Calibration Certifi cate

Level 2

Declaration and Calibration Equipment List

DY / DYA

L2

Level 3

Declaration and Primary Standard List

DY / DYA

L3

Level 4

Declaration and YOKOGAWA Measuring

DY / DYA

L4

Material certifi cates: Mill sheets

Item to be

specifi ed

1. Meterbody

DY

M01

1. Meterbody, 2. Shedder bar

M02

1. Meterbody, 2. Shedder bar, 3. Bottom plug

M03

1. Meterbody, 2. Shedder bar, 3. Bottom plug, 4. Welding rod

M04

Material certifi cates: 3.1

3.1 certifi cate to be attached according to EN10204.

DY

Item to be

specifi ed

1. Meterbody

E01

1. Meterbody, 2. Shedder bar

E02

1. Meterbody, 2. Shedder bar, 3. Bottom plug

E03

1. Meterbody, 2. Shedder bar, 3. Bottom plug, 4. Welding rod

E04

PMI test certifi cate

Positive Material Identifi cation certifi cate to be attached for the main 3 chemical components of

specifi ed materials. Each certifi cate to be attached.

DY

Item to be

specifi ed

1. Meterbody

PM1

1. Meterbody, 2. Shedder bar

PM2

ASME welding

documents submission (Note 10)

1. Welder/Welding Operator Performance Qualifi cation (or Welder Qualifi cation Record)

2. Welding Procedure Specifi cation (WPS)

3. Procedure Qualifi cation Record (PQR)

Each certifi cate to be attached.

The customer’s name and job name to be specifi ed when ordered.

DY

WP

Item to be

specifi ed

1. Welded portion for the bottom plug

2. Welded portion for the fl ange in case of the welding construction

Dye Penetrant test certifi cate

Dye Penetrant test certifi cate for the welded portion to be attached.

Each certifi cate to be attached.

DY

2. is for DY250 to

DY400.

PT

Item to be

specifi ed

1. Welded portion for the bottom plug

2. Welded portion for the fl ange in case of the welding construction

3. Criterion: ASME B31.1

(Note 1) Up to 30 alphanumeric characters can be engraved on the stainless tag plate. Capital/small letters are available for

BRAIN communication “-D” and F

OUNDATION

Fieldbus “-F”. Only capital letters are available for HART communication “-E”

or “-J”.

(Note 2) There is a case that calibration water should stay in the meter tube. So this is not degrease treatment in the strict sense.

(Note 3) The output is set 3.6mA or less (Standard type is set 21.6mA or more at shipping).

(Note 4) The electrical connection turn to a downstream side.