2 setting parameters required for operation – IAI America ACON-PO User Manual

Page 50

40

4. Operation Using I/O Signals

4.2.2

Setting Parameters Required for Operation

The following parameters must always be set prior to every operation.

(These parameters are all you need to set to perform operations that only involve positioning.)

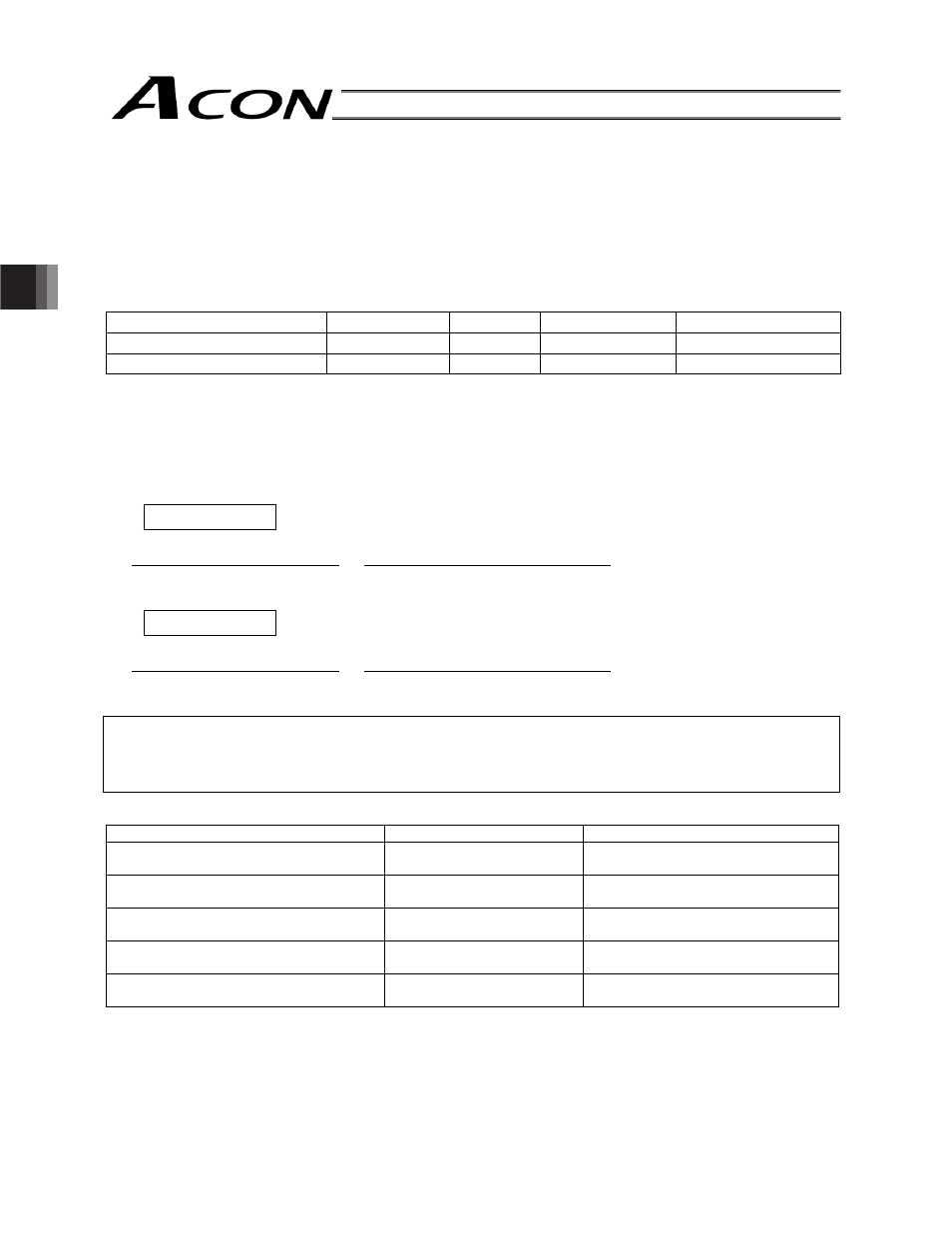

(1) Electronic gear

User Parameter Nos. 65 and 66 (Electronic gear numerator and denominator)

Name

Symbol

Unit

Input range

Default (reference)

Electronic gear numerator

CNUM

-

1 ~ 4096

200

Electronic gear denominator

CDEN

-

1 ~ 4096

15

These parameters are used to determine the unit travel distance of the actuator per one pulse in input command

pulse train.

Unit travel distance of linear-motion axis = Minimum travel unit (1, 0.1, 0.01 mm, etc.)/pulse

Unit travel distance of rotational axis = Minimum travel unit (1, 0.1, 0.01 deg, etc.)/pulse

Calculation Formula for Electronic Gear

Linear-motion axis

Electronic gear numerator (CNUM)

Encoder pulses (pulses/rev)

Electronic gear denominator

(CDEN)

=

Ball screw lead length (mm/rev)

x Unit travel distance (mm/pulse)

Rotational axis

Electronic gear numerator (CNUM)

Encoder pulses (pulses/rev)

Electronic gear denominator

(CDEN)

=

360 (deg/rev) x Gear ratio of rotational axis

x Unit travel distance (deg/pulse)

Reference

The actuator speed is calculated as follows:

Speed = Unit travel distance x Input pulse frequency (Hz)

Take note that if the unit travel distance is too small, the actuator may not be able to reach the maximum speed.

List of encoder pulses and leads length by model

Actuator type

Encoder resolution

Lead length

RCA or RCA2 other than RCA2-

N

800

(Pulse/rev)

Check the lead marking on the side

panel of the controller.

RCA2-

N

1048

(Pulse/rev)

Check the lead marking on the side

panel of the controller.

RCL-SA1L/SA4L/SM4L/RA1L

715

(Pulse/rev)

30.03 mm

RCL-SA2L/SA5L/SM5L/RA2L

855

(Pulse/rev)

35.91 mm

RCL-SA3L/SA6L/SM6L/RA3L

1145

(Pulse/rev)

48.09 mm