Ransburg, Appendix k: error codes, Rcs-2 user manual - appendix – Ransburg RCS 2 Ratio Control System User Manual

Page 71

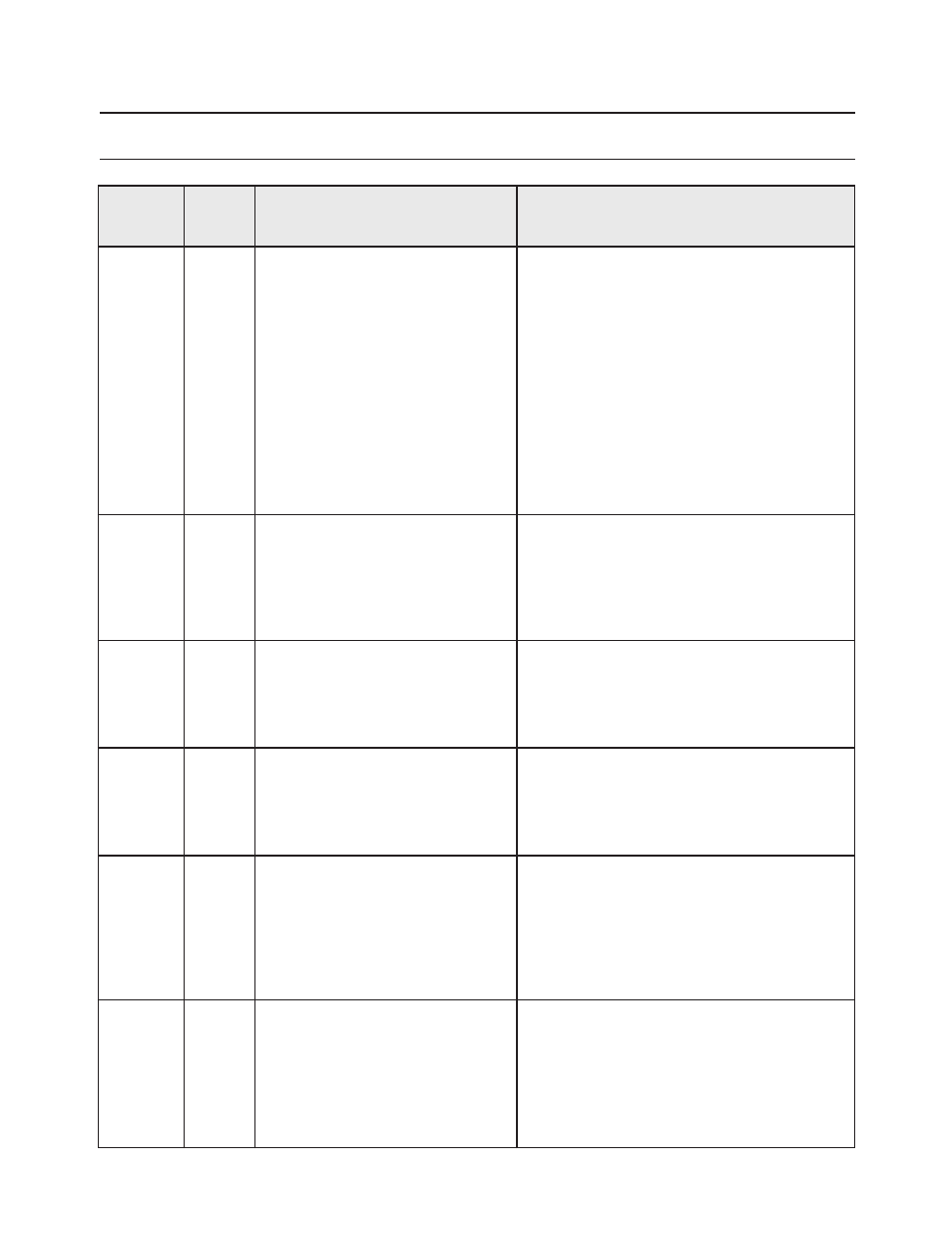

APPENDIX K: ERROR CODES

Error

Name

Description

Explanation and/or Possible Causes

Input

Under

Pressure

Input

Over

Pressure

Output

Under

Pressure

Output

Over

Pressure

Flow Rate

Out of

Tolerance

Hardener

Flow Loss

Pump inlet pressure is below the

Minimum Pressure value specified

in the Channel Configuration

Pump inlet pressure is above the

Maximum Pressure value specified

in the Channel configuration.

Pump outlet pressure is below the

Minimum Pressure value specified

in the Channel Configuration

Pump outlet pressure is above the

Maximum Pressure value specified

in the Channel Configuration

The difference between the

commanded flow rate (RPM) of the

pump and the actual flow rate

measured from the feedback signal

exceeds +/- 2 times the Flow Rate/

Ratio Tolerance Percentage value

specified in the Gun Configuration

The electrical current from the

Hardener Flow sensor is less than

1 milliamp

1. No material available to pump inlet.

2. Material supply pressure is too low.

3. Loss of supply air to the E/P transducer

that controls the pump inlet pressure.

4. Loss of electrical supply or control signal to

the E/P transducer that controls the pump

inlet pressure.

5. Failure of the E/P transducer that controls

the pump inlet pressure.

6. Failure of the pressure regulator that

controls the pump inlet pressure.

7. Failure of the pump inlet pressure sensor.

8. Minimum Inlet Pressure value specified in

the Channel Configuration is too high.

1. Failure of the E/P transducer that controls

the pump inlet pressure.

2. Failure of the pressure regulator that

controls the pump inlet pressure.

3. Maximum Inlet Pressure value specified in

the Channel Configuration is too low.

1. Pump is not turning.

2. Material is not available at pump inlet.

3. Failure of pump outlet pressure sensor.

4. Minimum Outlet Pressure value specified in

the Channel Configuation is too high.

1. Restriction in the fluid line.

2. For Autmatic guns, failure of applicator

trigger valve.

3. Maximum Outlet pressure value specified

in the Channel Configuration is too low.

1. Loss of feedback signal from motor

amplifier or flow meter.

2. Incorrect Calibration Factor in Channel

Configuration.

1. There is no hardener flow due to the pump

not operating or an obstruction in the

harener fluid line.

2. Electrical connection problems.

3. Failure of Hardener Flow sensor.

Source

Channel

Card

Channel

Card

Channel

Card

Channel

Card

Channel

Card

Channel

Card

RCS-2 User Manual - Appendix

68

LN-9407-00.2

Ransburg