Ransburg, F12: shutdown, User-interface software buttons: (top of screen) – Ransburg RCS 2 Ratio Control System User Manual

Page 51: Rcs-2 user manual - operation

F10: Save To File - This button allows the operator

to save flush and load sequences to any writeable

media. All flush and load sequences for all guns

are saved in a file named

ColorChg.par.

Note that there are nine solenoid valves whose text

descriptors are in red. (Paint, Resin Bypass, Resin

Pump Flush, Trigger Solenoid, Resin Override,

Dump Valve, Catalyst Select, Catalyst Solvent,

and Catalyst Override) These functions may not

always be required in all systems and therefore

can be renamed and used for other functions.

Inside of the RCS-2 folder on the hard drive of the

user-interface computer there is a text file named:

Solenoid_Valves.txt. In it the above 9 valves are

named. Users are free to rename any or all of those

valves and use them for other functions during

the color change sequences that they program.

Simply exit the user-interface software, open the

file with any text editor (Wordpad, etc.), change

the names as required, and resave the file. The

next time the user-interface software is opened,

it will use the new names when the color change

sequencer screens are opened.

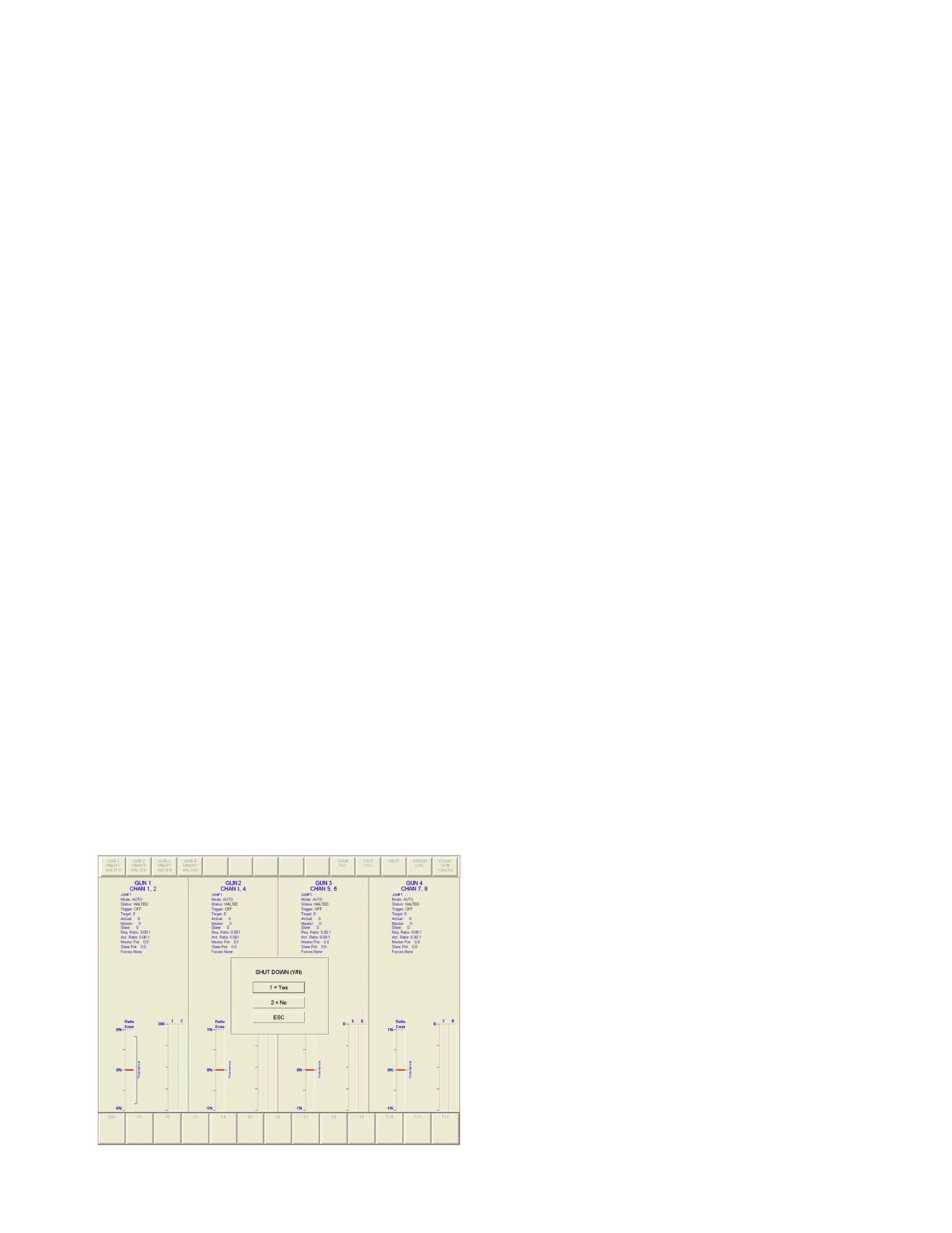

F12: Shutdown

This function key allows the RCS-2 to perform an

orderly shutdown of the Windows XP Embedded

operating system. The operating system (stored

on the flash drive, drive C:\) can be damaged if

the unit is powered off with the power switch on

the front door of the controller without performing

this shutdown procedure first.

User-Interface Software Buttons:

(top of screen)

On the top-right of the user interface screen, there

are 5 buttons. The function of these buttons are

as follows…

Channel Fill - This function allows the operator

to run any of the 8 pumps at their maximum flow

rate (typically 150 RPM). This is typically used

for flushing purposes and for rapidly getting ma-

terial from a color valve stack down to the pump,

prior to using Fast Fill. The gun that the channel

is assigned to must be in the Ready state before

it will be allowed to channel fill. Also, Fill Enable

must be set to Yes for the channel in the Config.

Channel parameter screen. When the Channel

Fill button is pushed, the operator will be prompted

with a display showing 8 buttons (one for each

channel). The instant any of those buttons are

pushed, the pump for that channel will run at its

maximum RPM (typically 150 RPM). Make sure

the applicator is triggered prior to pushing these

buttons or an overpressure fault may occur. Any

combinations of these buttons can be turned on

simultaneously. Pushing the button a second time

will take that channel out of Channel Fill Mode

and stop the pump (if it was put in Channel Fill

Mode from this screen). If either the enter or the

escape button (below the channel number buttons)

is pushed, the Channel Fill Screen will be exited

and all pumps that had been put in Channel Fill

Mode from this screen will stop.

Fast Fill – This function allows the operator to fill

the fluid lines as fast as possible at the ratio cur-

rently programmed for the loaded job number. That

is, one of the two pumps will run at its maximum

RPM (typically 150 RPM), and the other pump

will be slaved to it to deliver material at the proper

ratio. The software will determine which of the two

pumps will run at the maximum RPM based on

the ratio setting and the two pump sizes. In order

to run a gun in Fast Fill Mode, the gun must first

be in Run Mode prior to selecting Fast Fill. When

the user pushes this button, they are presented

with a screen showing gun numbers 1 through 8.

The user simply pushes the gun number that they

wish to put in Fast Fill Mode. Note that the pumps

will start running immediately, so make sure the

applicator is triggered or either an overpressure

RCS-2 User Manual - Operation

48

LN-9407-00.2

Ransburg