Burkert Type 8619 User Manual

Page 55

53

Adjustmentandcommissioning

CMD SAFE: Confirm (choose "Mode: ON") or do not confirm (choose "Mode:OFF") the use of a fallback

position on the output when the "System switch" event (see chap. 8.10.17) has the state "ON". When use of the

fallback position is confirmed, enter a fallback position value of between 0 and 100% for each output.

press this dynamic key to enter

the setpoint value.

1

13:40

1

0

0

F2:ONOFF

250.0

µS/cm

PV

500.0

µS/cm

SP

0.00

%

CMD1

Off

F3 Dos.St

Measured value of the process variable chosen

Value of the standard setpoint

result of the ONOFF function

Associated Time dosing; dosing status is "Off".

See Figure 41 for the various states of a dosing operation

SETP

MENU

2010/06/29

Figure 42 :

Example of a view, in Process level, of the ONOFF function associated with a time dosing function

8.10.14. configuring a piD (proportional integral drift) control

function

This function is available as an option. See chap.. 8.10.4.

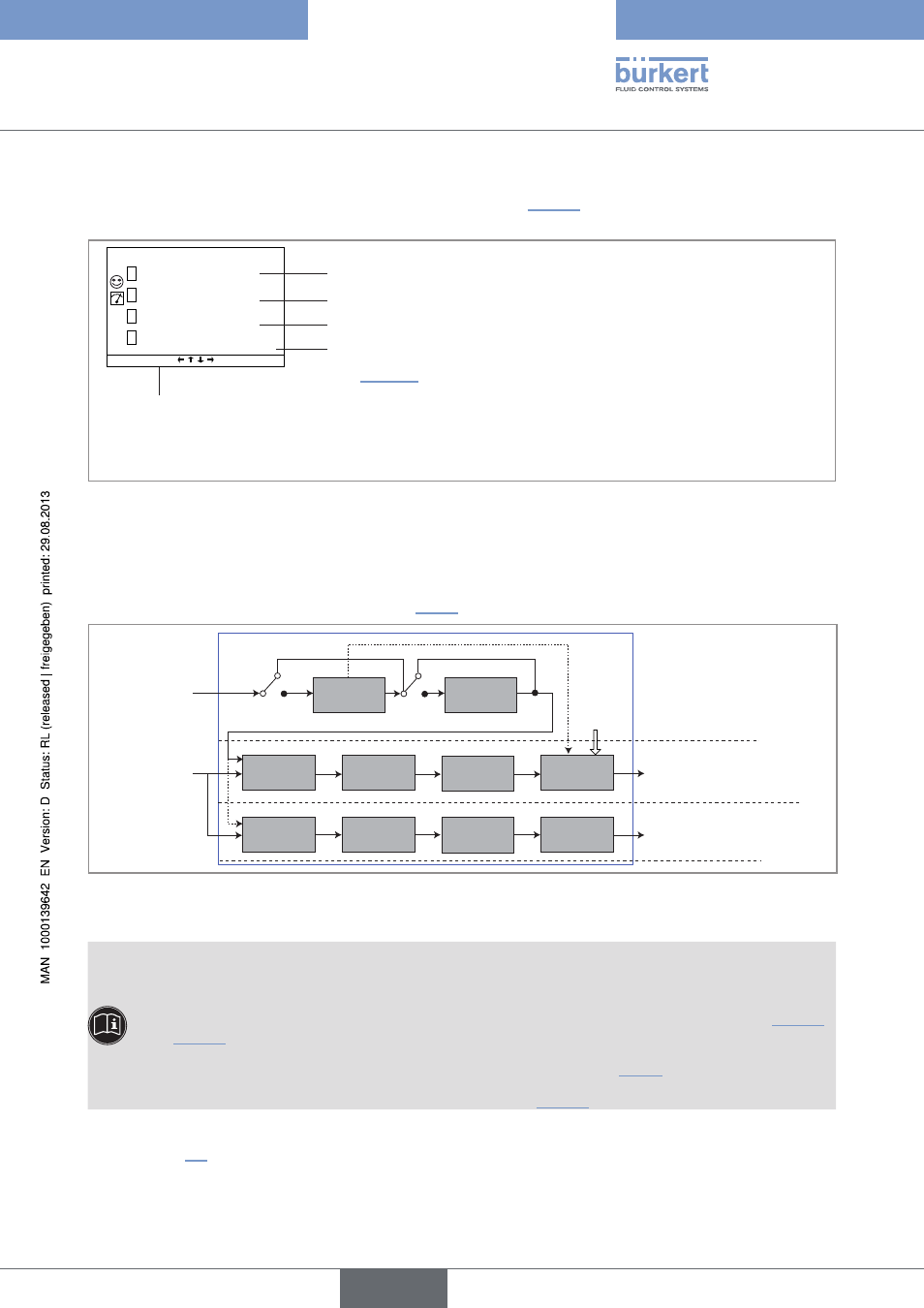

Setpoint (in-

ternal or ex-

ternal) (SP)

Process

input (PV)

Splimit

Cutoff

PID function

A

single

channel

Two

channels

Direction of the

actuator

Demarcation of

the result

Fallback

position

PID function

Direction of the

actuator

Demarcation of

the result

Fallback

position

system

switch

result

(Fx:PID1)

result

(Fx:PID2)

Figure 43 :

PID function

Once the function has been configured and activated, the result "Fx:" calculated is available in the list of

process variables on the "M0:MAIN" board. This list appears in the output configuring, user view config-

uring and datalogging menus to:

• Assign the result "Fx:" calculated to a physical output (analogue, AO, or digital, DO) (see chap. 8.10.22

and 8.10.22).

• Display the result "Fx:" on one of the user defined "Ux" views: see chap. 8.10.8.

• Logging the values of "Fx:" using the datalogger: see chap. 8.10.18.

Refer to chap. 8.9 to access Parameters menu.

Type 8619

english