0 using the lm93 – Rainbow Electronics LM93 User Manual

Page 29

15.0 Using The LM93

(Continued)

size and cost of the inductor and other components used in

the output stage. The PWM outputs of the LM93 can operate

up to 22.5 kHz with a step size of 6.25%.

The LM93 fan control method uses a look up table that

contains 12 temperature offset settings and a base tempera-

ture. The actual duty cycle value for each step is pre-

assigned. There are two possible assignments. They are

dependent on the PWM output to Zone binding and the

PWM output frequency. The temperature of each step is

determined by the programmed offsets and zone base tem-

perature. There are two sets of offset values, one set applies

to Zone 1 and Zone 2 while the other set applies to Zone 3

and Zone 4. Each zone has an independent base tempera-

ture. A measured temperature can then be correlated to a

PWM duty cycle level. Programmable temperature hyster-

esis is included that prevents fan speed oscillations between

two steps. Each offset table has one hysteresis value as-

signed to it. Therefore, Zones 1 and 2 share a hysteresis

value while Zones 3 and 4 share a different hysteresis value.

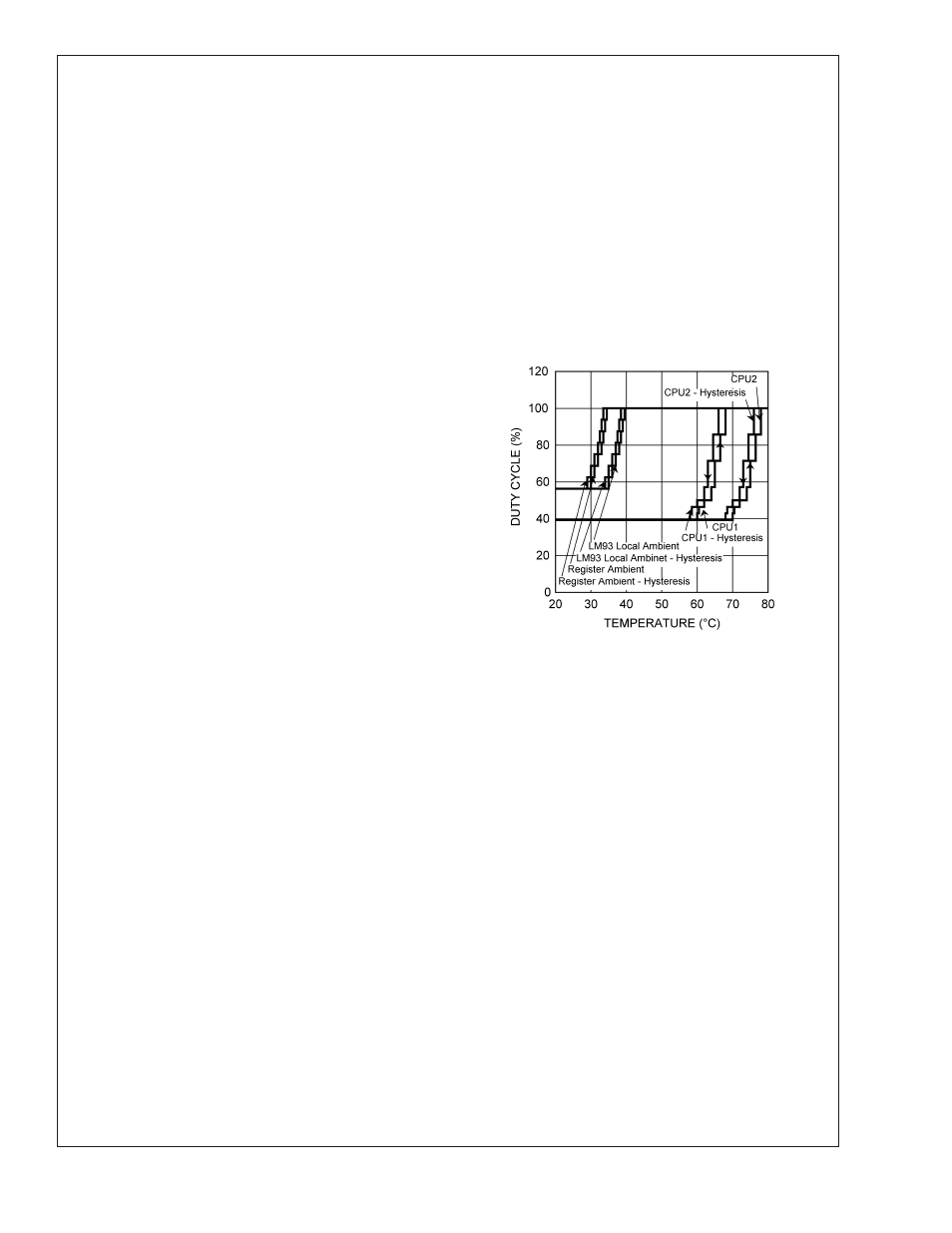

Shown in Figure 1 is a plot of one example of the transfer

function of the PWM output duty cycle (%) with respect to

temperature (˚C) for Zone 1 - 4. Table Zone 1/2 (CPU1 and

CPU2) Table and Table Zone 3/4 (LM93 Ambient and Exter-

nal Ambient) Table show the actual register values used for

the plot. Available for download from the National web site,

at www.national.com/appinfo/tempsensors under design

tools, is an excel spread sheet that allows you to enter the

register values then generate curves similar to the ones

shown in Figure 1 as well as tables similar toTable Zone 1/2

(CPU1 and CPU2) Table and Table Zone 3/4 (LM93 Ambient

and External Ambient) Table. For this example: Zones 1 and

2 are bound to PWM1 and PWM1 is programmed to have a

low frequency PWM signal; Zones 3 and 4 are bound to

PWM2 and PWM2 is programmed to have a high frequency

PWM signal. As can be seen in Table Zone 1/2 (CPU1 and

CPU2) Table and Table Zone 3/4 (LM93 Ambient and Exter-

nal Ambient) Table the duty cycle assignments differ. Low

frequency PWM output assignments have a non-linear incre-

mental increase in the duty cycle as shown in Table Zone 1/2

(CPU1 and CPU2) Table while high frequency PWM assign-

ments have a linear incremental increase in the duty cycle as

shown in Table Zone 3/4 (LM93 Ambient and External Am-

bient) Table.

To minimize the size of the LM93’s lookup table structure,

temperature values in the registers are programmed as an

offset value of 4 bits. This offset gets added in a cumulative

manner to the 8-bit base temperature. The calculated tem-

perature is then used in the comparison that determines the

PWM output duty cycle. The minimum PWM (minPWM)

value sets the duty cycle when the measured temperature is

less than or equal to the base temperature. All offset values

that map to a PWM value less than or equal to the minPWM

setting must be set to zero as shown in Table Zone 1/2

(CPU1 and CPU2) Table and Table Zone 3/4 (LM93 Ambient

and External Ambient) Table. If the offset values are not set

to zero, the LM93 fan control circuitry may function unpre-

dictably.

Duty cycle levels may be skipped by setting their offset value

to zero. As shown in Table Zone 1/2 (CPU1 and CPU2) Table

, the 53.57% duty cycle step is skipped. When the tempera-

ture exceeds 74˚C for CPU1 and 64˚C for CPU2 the duty

cycle changes from 50% to 57.14%.

20068228

FIGURE 1. Example of the LM93 Fan Control Transfer

Function. Download an excel spread sheet from

www.national.com/appinfo/tempsensors that allows

you to enter the fan control register values and then

automatically generate a similar curve.

LM93

www.national.com

29