Generac Power Systems MC User Manual

Page 79

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

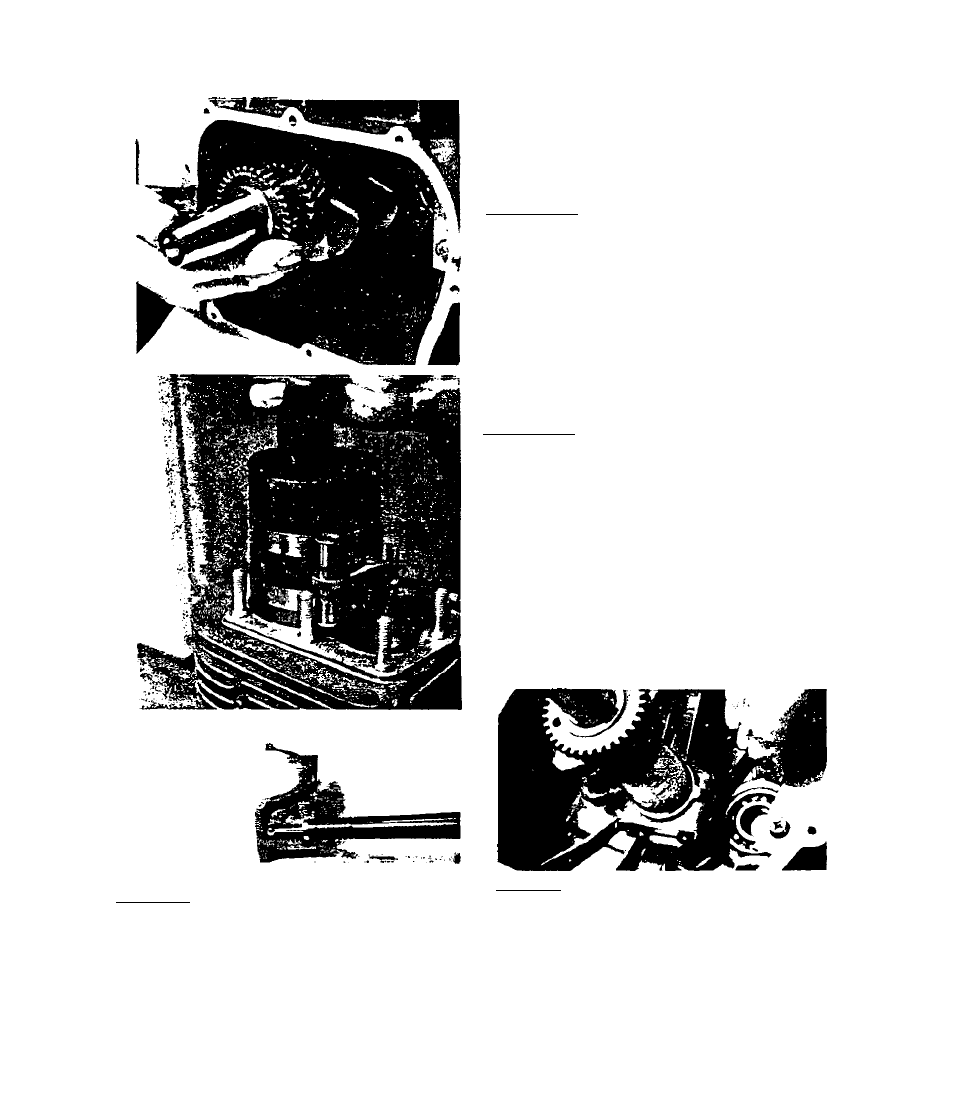

3* 3« 3« 8-Connecting rod and connect

ing rod cap are a matched set and

must be replaced as a set. Mark on

cap (see above) must align with id

entical mark on connecting rod dur

ing installation#

3# 3# 3# 6-Install crankshaft end

play shims. Install crankshaft. Use

care not to damage oil seal and

bearing#

3# 3# 3« 7-Install rings onto piston#

Ring end gaps should be staggered.

See Section 3.3.2, INSPECTION AND

REPAIR, for proper ring locations

In piston grooves. Slide conuectiiig

rod with piston installed do^^

through cylinder until rings contact

top of cylinder block. Then use ring

compressor to compress rings Into

piston grooves. With rings compress

ed, tap piston into cylinder. While

tapping, align connecting rod with

crankshaft. When rings are engaged

by cylinder, remove ring compressor.

3.3.3.9-Lubricate bearing surfaces

of connecting rod and cap. Install

connecting rod cap, oil splasher,

and lock tab onto connecting rod.

Retain with connecting rod bolts.

Use torque wrench and tighten bolts

to 18 - 22 foot-pounds. Bend ends of

lock tab over bolt heads.

3.3-9