Generac Power Systems MC User Manual

Page 75

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

3.3.2- INSPECTION AND REPAIR

3.3.2.1- CYLINDER BLOCK

Replace cylinder block i£:-

a. )-Fins are broken or cracked

b. )-Head mounting surface is warped

c. )-Cylinder inner diameter is greater than 0,5 mm oversize.

If cylinder is to be rebored, first determine whether to bore 0,25 mm

or 0,50 mm oversize. Use any standard commercial hone of a suitable

size. Chuck the hone in a drill press having about a 600 rpm speed.

Use standard boring procedures.

Valve seats require grinding only if pitted or scored. If seats are

not pitted or scored, lapping will provide a satisfactory valve seat.

Valves must be lapped to seats when seats are reground,

3.3.2.2- ENGINE GEAR COVER

Clean and degrease engine gear cover. Replace if cracked, warped, or

damaged,

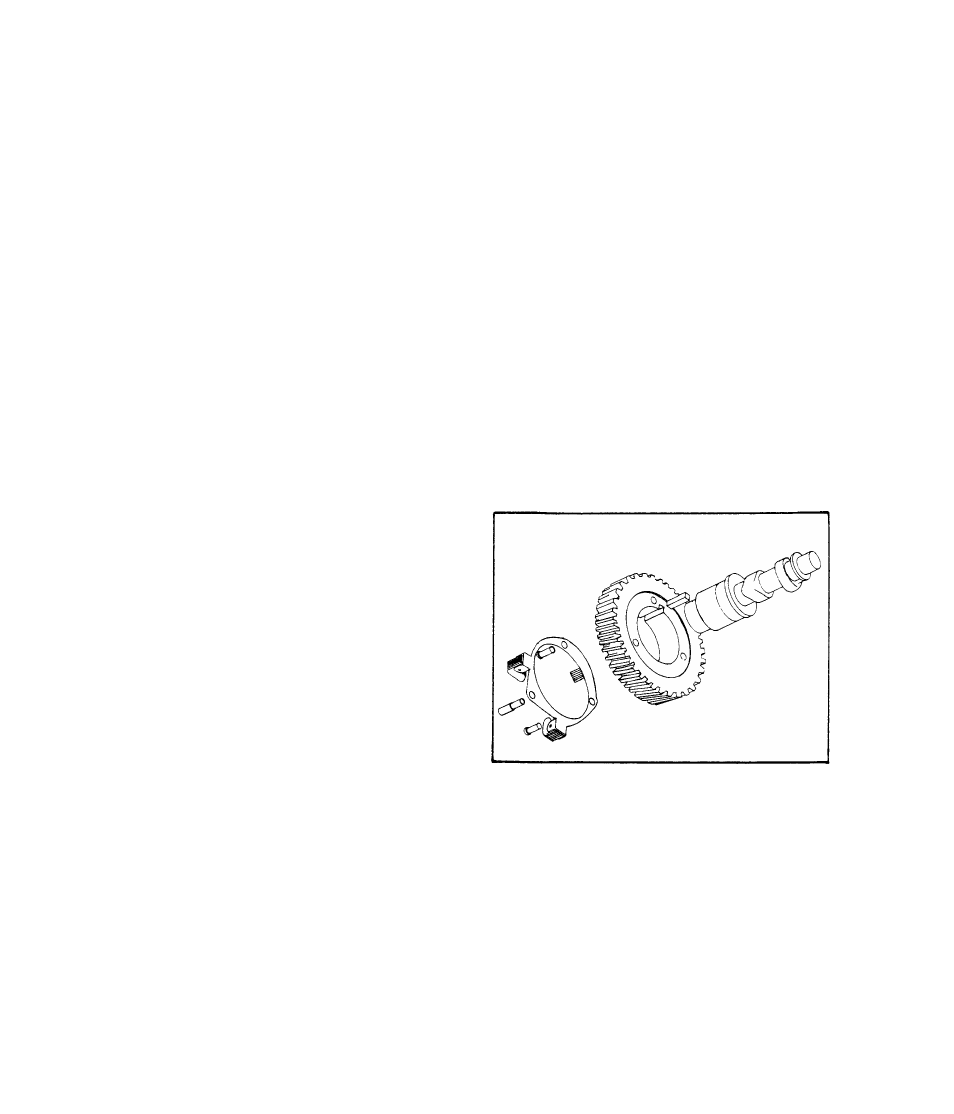

3.3.2.3- CAMSHAFT

Clean camshaft in non-flammable

solvent and blow dry. Replace a

camshaft that shows signs of

wear or scoring. If a damaged

camshaft gear is replaced, also

replace the mating crankshaft

gear. If keyways are damaged or

worn, replace camshaft. Inspect

keys, replace any that are dam

aged or worn excessively. Repl

ace flyweight or governor shaft

if damaged.

3.3.2.4-CRANK SHAFT

Replace crankshaft if:-

a. )- Damaged threads can’t be dressed

b. )- Bearing surfaces are worn, scratched or damaged

c. )- Flat spots have developed

d. )- Crankshaft is bent - NEVER TRY TO STRAIGHTEN A BENT CRANKSHAFT

e. )- Crankpin is out-of-round more than 0,002 inch

When installing a crankshaft, always lubricate bearing surfaces. If the

camshaft drive gear on crankshaft is replaced, replace the mating cam

shaft gear as well. The crankshaft must be shimmed during assembly to

establish an end play of 0,0039 to 0,0118 inch.

3,3-5