Generac Power Systems MC User Manual

Page 33

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

C.)- Check Wire No. 14, between Fuel Pump and terminal strip, for open

or shorted condition,

RESULT:- Wire No. 14 checks good............ Continue Diagnostic tests

Wire No. 14 cheeks bad............ Repair/replace Wire No. 14

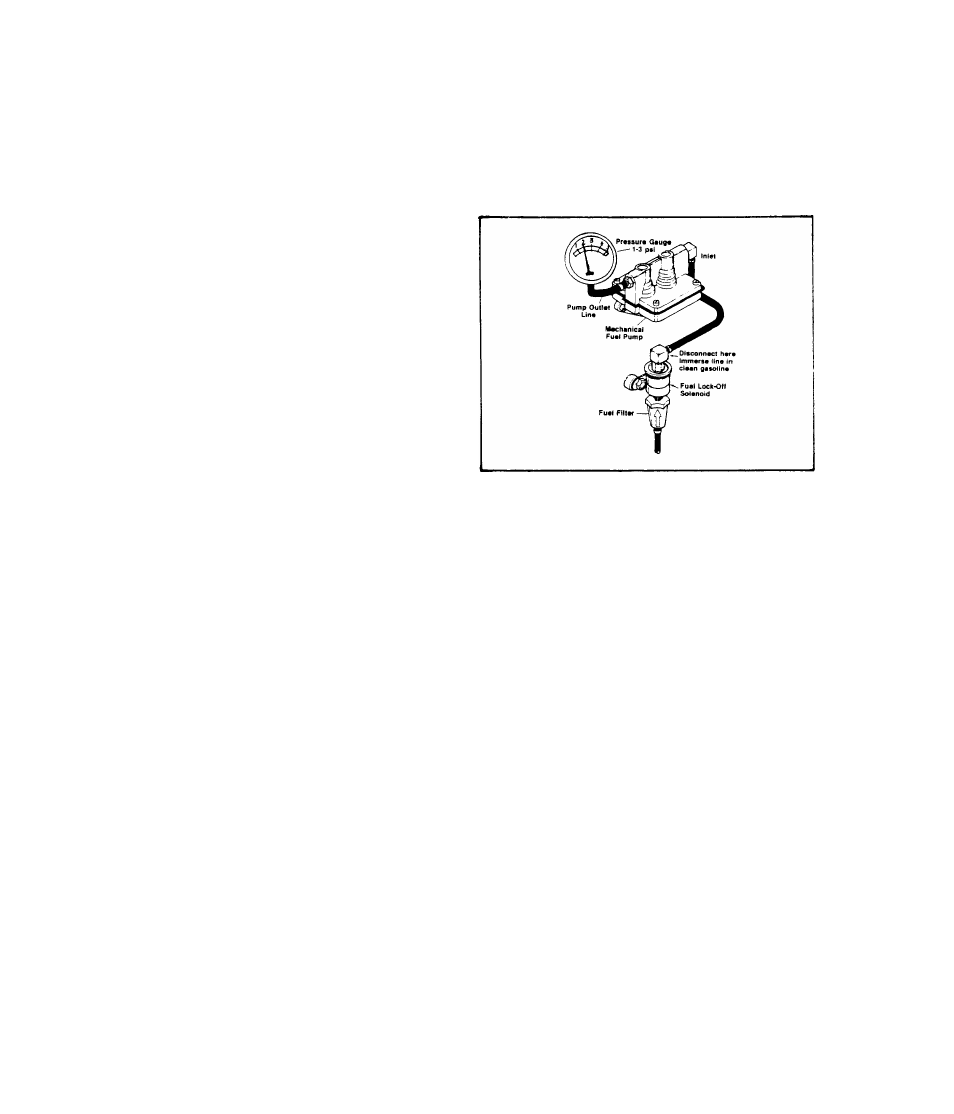

UNITS WITH MECHANICAL FUEL PUMP

Disconnect Piomp Outlet Line at the

carburetor inlet. Connect a press

ure gauge to the line. Disconnect

Pump Inlet Line at the £ue-l lock-

off solenoid and immerse line in

clean gasoline. Crank engine. The

pressure gauge should indicate 1-

3 psi.

RESULT:- Pressure gauge read 1-3 psi........ Continue Diagnostic Tests

Pressure gauge does -not read 1-3 psi........... Replace Pump

TEST 22;- CHECK INSTALLATION

Check alternator installation for:-

1. )- Any other filter screens in the fuel supply line from gas tank.

If other filters are found, check for clogging.

2. )- A Shutoff Valve in the fuel supply line. Make sure Shutoff Valve

is OPEN.

3. )- Anything that might restrict cooling air flow, such as air inlet

or exhaust openings too small, clogged air inlet screening, etc.

If cooling air flow is inadequate, interior compartment tempera

tures will be high resulting in possible fuel line vapor lock,

4. )- Alternator fuel pump located too high above fuel supply tank.

Maximum vertical lift for MC units with an electric pump is app

roximately 18 inches, for mechanical fuel pumps approximately 9

inches.

TEST 23- CARBURETOR

This test covers the procedures for adjustment of the carburetor Idle

Speed Stop Screw, Idle Mixture Adjusting Screw, and High Speed Jet Ad

justing Screw. In addition to these adjustments, the float valve and

its seat should be checked, as well as the float level.

2.2-11