Generac Power Systems MC User Manual

Page 39

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

A.)- Adjust Carburetor as outlined in Test 23, The Carburetor must be

adjusted BEFORE attempting to adjust the Governor,

RESULT Problem is corrected...........................Test completed

Engine ’’hunts’’ and/or a-c voltage

or frequency is incorrect.................Go to Paragraph B

_ Carburetor

Throttle Lever

TEST 32;- GOVERNOR

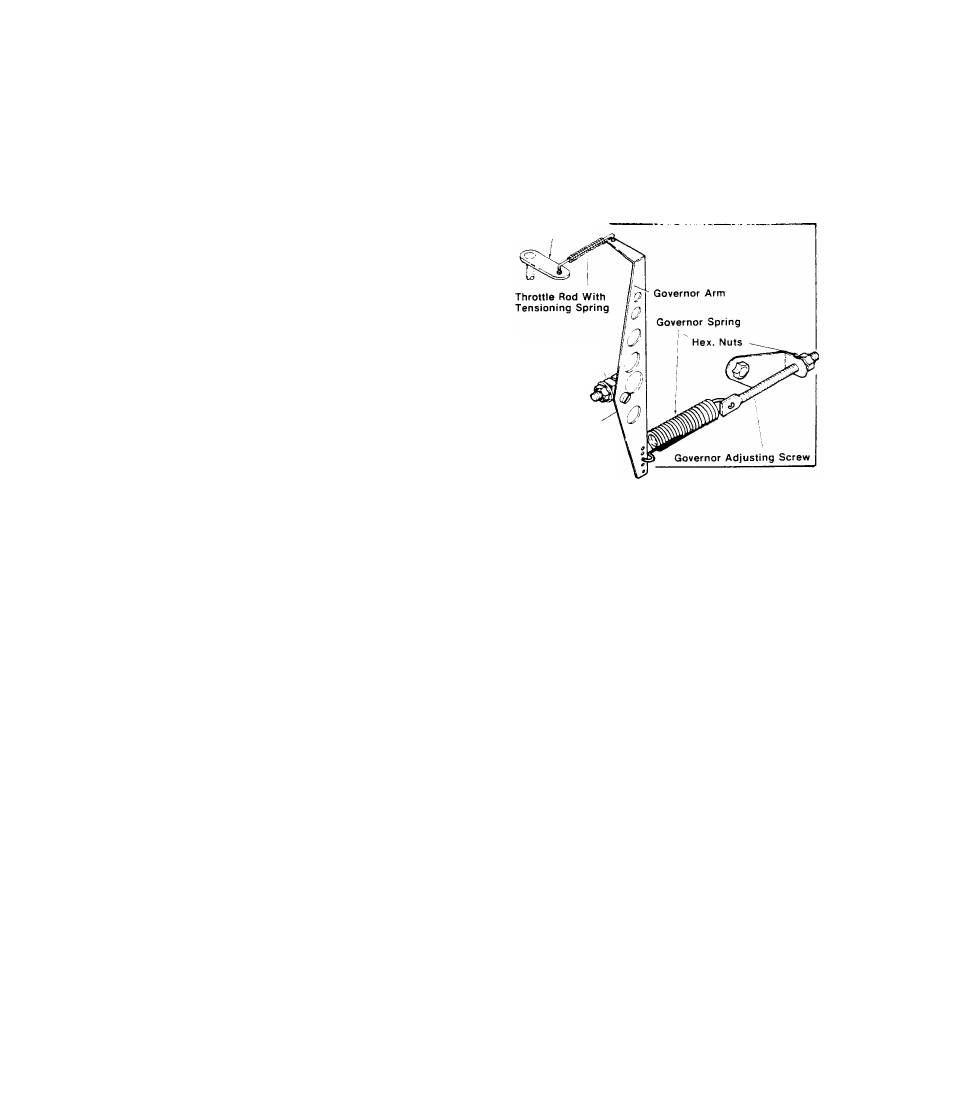

B,)-Make sure Governor Spring is

connected to Governor Arm and to

Governor Adjusting Screw, Loosen

Engine Governor Shaft Clamp Nut

and turn Engine Governor Shaft

counterclockwise as far as it

will go. Then tighten Governor

Shaft Clamp Nutand torque to 110

inch-pounds.

Engine Governor

Shaft Clamp Bolt,

Nut and Washers

Engine

Governor

Shaft

RESULT:- Engine runs normal, provides

62 Hertz at no—load.......................... Test completed

Engine hunts and/or a-c voltage

or frequency is incorrect........ ........ Go to Paragraph C

C,)- With engine running, adjust hex nuts at end of Governor Adjust

ing Screw to obtain 62 Hertz at no-load. One hex nut serves as a jam

nut - make sure this nut is tight when 62 Hertz is obtained,

RESULT:- Engine runs normal,,,,.,,"................ ...Test completed

Engine hunts............... Set Carburetor for richer mixture

NOTE

All mechanical governors have a normal offspeed fluctuation,

This is the reaction time of the governor,

TEST 33;- CHECK FREQUENCY

Use an accurate Frequency Meter to check alternator output frequency.

Frequency should be 62 Hertz at no-load. With a normal electrical load

applied, frequency should be 59-62 Hertz and stable (disregarding the

normal offspeed fluctuation).

2.2-17