Generac Power Systems MC User Manual

Page 34

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

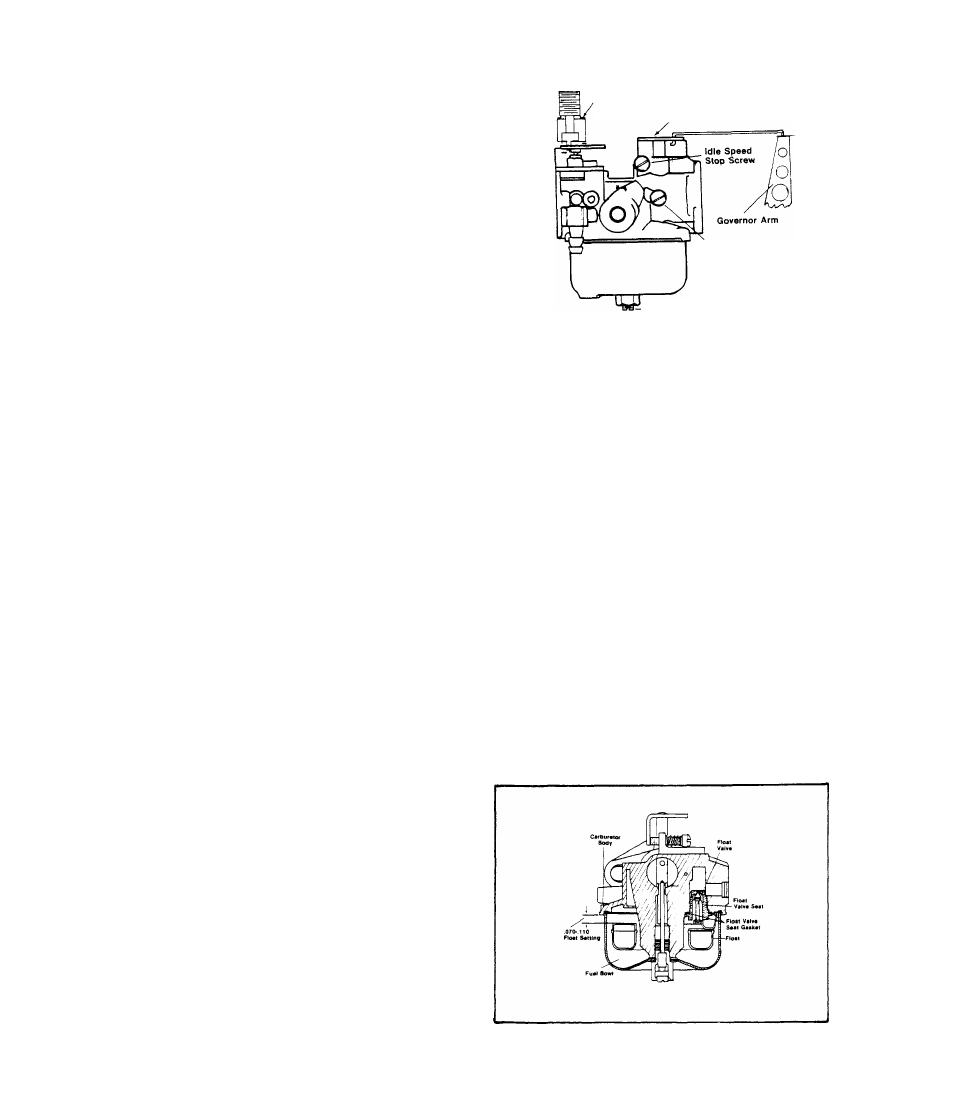

A.)-Turn High Speed Jet Adjusting

Screw clockwise until it just bot

toms. DO NOT USE EXCESSIVE FORCE.

Then turn High Speed Jet Adjusting

Screw counterclockwise about

turns. Perform the same initial ad

justment on the Idle Mixture Adjust

ment Screw. This initial adjustment

should permit the engine to be star

ted and warmed up.

Automatic Choke

Throttle Lever

Idle Mixture

Adjusting Screw

. High Speed Jet

Adjusting Screw

RESULTS:- Engine starts............................. Go to Paragraph B

Engine will not start......... ..... ...... Go to Paragraph D

B. )- Set VOM to "250V,” scale and to "AC". Connect the meter test leads

to a convenient AC outlet powered by the alternator. Hold the Carburet

or Throttle Lever against its Idle Speed Stop Screw, Adjust Idle Speed

Stop Screw until meter indicates 60 Volts a-c. When a 60 Volt reading

is obtained, turn Idle Mixture Adjusting Screw until voltage starts to

drop off. Then turn the screw in the opposite direction until voltage

reading again starts to decrease. Finally, reverse direction again and

turn the screw until the highest voltage reading is obtained. Release

Throttle Lever and let engine accelerate and stabilize,

C. )- With engine running at governed speed, apply a normal load to the

alternator. Connect an accurate frequency meter to the unit’s a-c out

put, Turn the High Speed Jet Adjusting' screw slowly clockwise then

counterclockwise until the highest frequency is obtained. When the Jet

is set for the highest possible frequency, turn adjusting screw count

erclockwise 1/8 turn.

RESULTS:- Engine starts and runs normally............Discontinue Tests

Engine will not start or starts and runs

rough....................... .............. Go to Paragraph D

D.)- Remove Fuel Bowl from Carbur

etor Body. Inspect Float Valve,

Seat and Gasket for damage, dirt

or wear. Replace defective compon

ents. Also check for proper Float

setting. Top of Float should be

0.070 - 0.110 inch below Carburet

or Body mounting Flange. See illu

stration at right.

2.2-12