Generac Power Systems MC User Manual

Page 77

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

CTLINCW

PISTON

,pi3TON R

ing

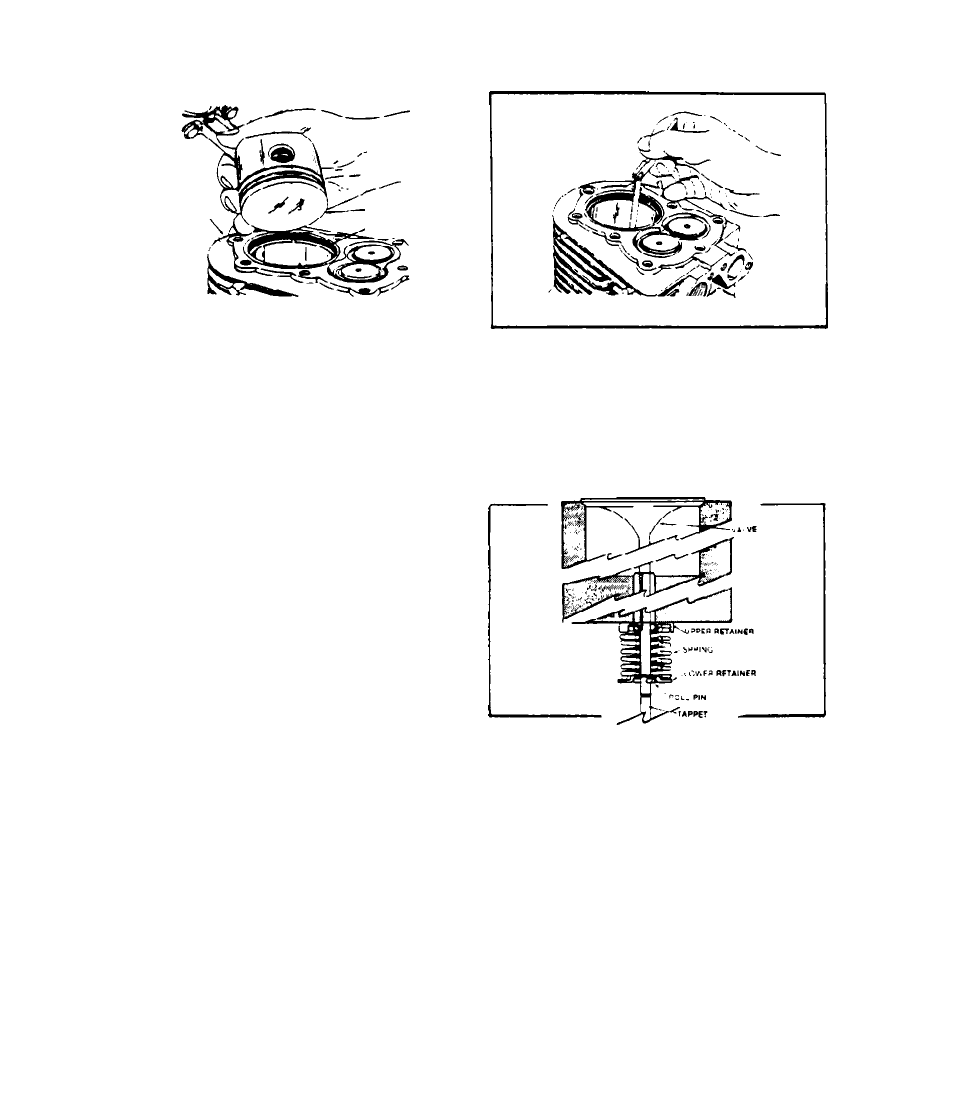

Check ring gaps on worn rings to

determine if rings should be re

placed. Check gaps on new rings

to determine if cylinder should

be rebored. To check ring gap,

square the ring in the cylinder

bore as shown above.

After squaring the ring in bore,

use feeler gauge to check ring

gap.

3.3.2J-VALVES

Intake.and exhaust valves are NOT

identical - intake valves are id

entified by the letter ”1”, exhaust

valves by an "E**.

Clean valve parts in iion-Clainmahle solvent. Remove carbon from valves.

Replace distorted or damaged valves. If valves are useable, they may

be ground to a 45 degree angle. When new or re-ground valves are to be

installed, lap them to ensue a gas tight fit. Lap valves as follows

1. Coat valve face sparingly with a fine grade of valve grinding comp

ound.

2. Rotate valve on valve seat. Lift valve from seat every 8 - 1 0

strokes to keep compound equalized on surface of valve seat.

3. Continue lapping until both the valve and seat has a smooth surf

ace. Clean thoroughly to remove all traces of lapping compound.

Dry thoroughly.

To obtain correct valve tappet clearance, grind ends of valve stems

off squarely. Use a V-block to hold valve stem square to grinding

wheel. After grinding, check for proper clearance as follows

3 . 3 - 7