4 management of the compressors – EVCO c-pro nano RACK User Manual

Page 52

C-PRO NANO RACK E C-PRO MICRO RACK APPLICATION MANUAL

Page 52

If the request for a shutdown remains, all the compressors are shut down, one by one, and at the end the value

of the inverter is brought to zero.

If the MinI parameter has been set, at every turn-on the inverter will keep that value as the starting value.

If the parameter for the speedUp time has been set, at every breakaway the inverter will assume the maximum

value for the seconds described by this parameter.

6.4

Management of the compressors

The program is able to manage up to a maximum of 4 compressors of equal power, divided into circuits and up

to 2 throttlings for each compressor. To each compressor, certain digital inputs for safety measures and digital

outputs for turn-on/shutdown and for potential throttlings may be associated.

The main configuration parameters are the following:

-

PG01 = Circuit number

-

PG11 = Number of compressors circuit 1

-

PG15 = Number of compressors circuit 2

-

PG04 = Number of throttlings

-

PG05 = Activation of compressor safety measures

The management of the compressors occurs through a setPoint and a differential that can be set by a parameter

and the reading of a pressure on the suction probe. Turn-on/shutdown is ensured by a thermo-adjustment and by

certain timings that protect the various breakaways.

6.4.1

Rotation of the compressors

The rotation of the compressors is a procedure that makes it possible to balance as much as possible the number

of functioning hours and the number of breakaways for each compressor. The rotation only refers to the

compressors and not to the single throttlings, it does not involve potential compressors that have been subject to

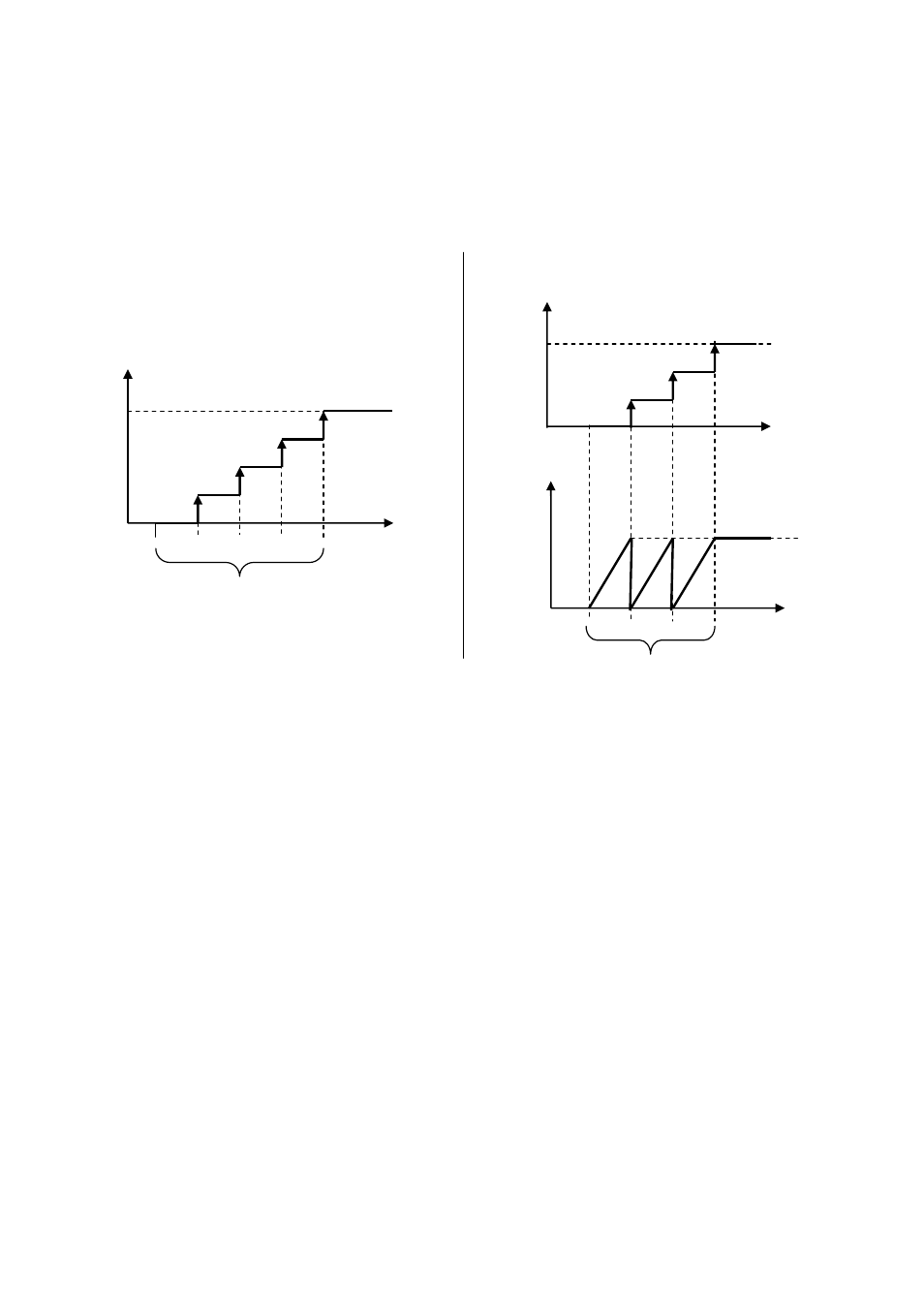

Example: 4 compressors without inverter

Example: 4 compressors with 1 inverter

Steps

4

Pressure

1

2

3

Out-band. Switching on

Steps

3

Pressure

1

2

Pressure

Inverter

100.00 %

Out-band. Switching on