Chapter 4, 1 required tools & instrumentation, 2 installing gas supply manometer – AERCO BMK 1.5 LN July 2011 User Manual

Page 44: Benchmark 1.5ln low nox boiler, Gf-120

CHAPTER 4: INITIAL START-UP

Page

44 of 152 PR2: 05/09/12

Benchmark 1.5LN Low NOx Boiler

Operation and Maintenance Manual

OMM-0041_0D

GF-120

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526-0288

4.2.1

Required Tools & Instrumentation

The following tools and instrumentation are necessary to perform combustion calibration of the

unit:

•

Digital Combustion Analyzer: Oxygen accuracy to ± 0.4%; Carbon Monoxide (CO) and

Nitrogen Oxide (NOx) resolution to 1PPM.

•

16 inch W.C. manometer or equivalent gauge and plastic tubing.

•

1/4" NPT-to-barbed fittings for use with gas supply manometer or gauge.

•

Small and large flat blade screwdrivers.

•

Tube of silicone adhesive

4.2.2

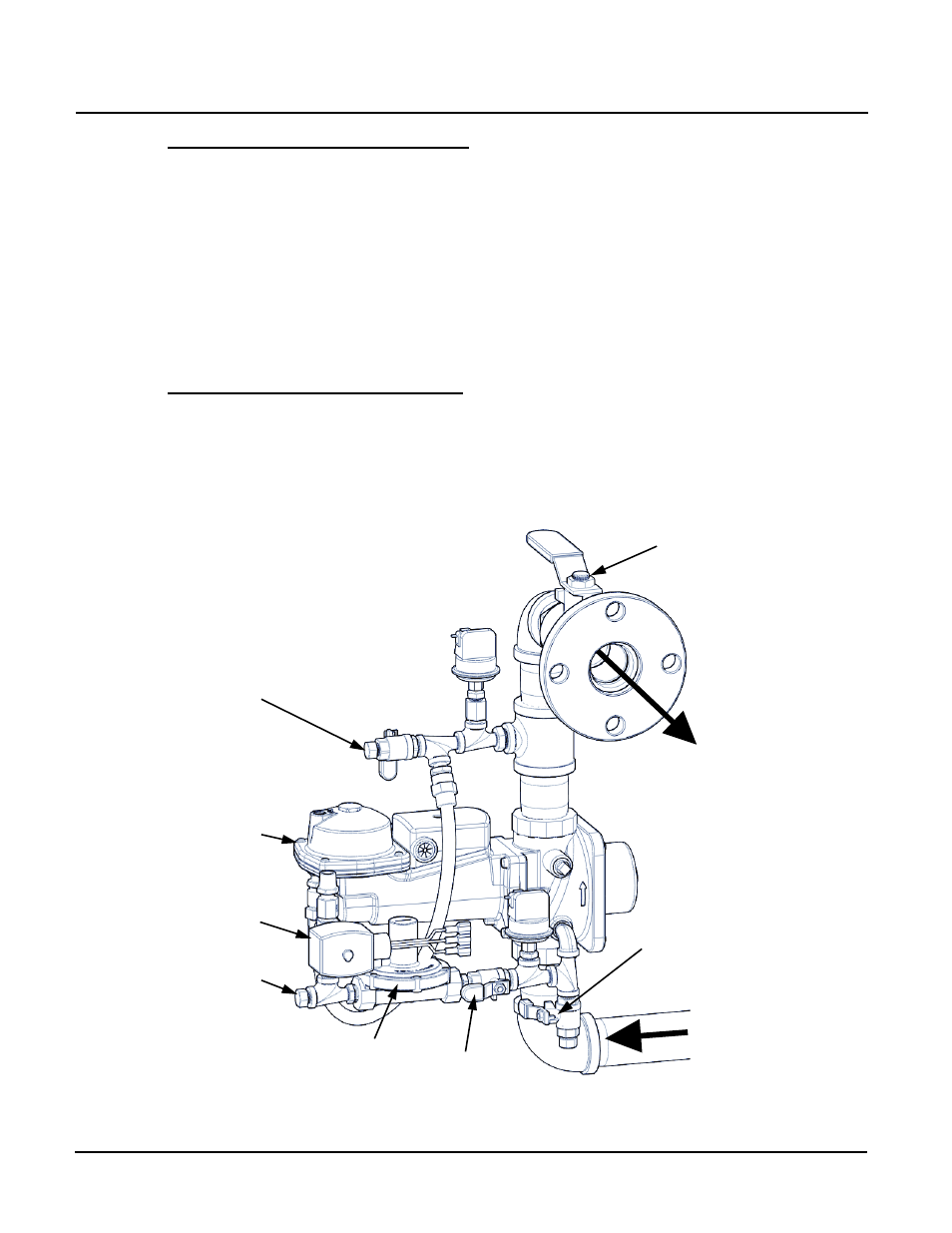

Installing Gas Supply Manometer

The gas supply manometer (or gauge) is used to calibrate the gas pressure to be monitored on

the downstream side of the SSOV during the Combustion Calibration procedures described in

paragraph 4.4.

The gas supply manometer is installed at the downstream location on the 1/4” NPT port shown

in Figure 4-1. Note that a 1/4” plug must be removed from the port in order to install the

manometer.

Figure 4-1: Combustion Calibration & RSI Manometer Installation Locations

TO

AIR/FUEL

VALVE

GAS INLET

SSO

RSI

SOLENOID

VALVE

RSI BLEED-

OFF VALVE

1/4” NPT PLUG

(INSTALL

MONOMETER HERE

FOR RSI PRESSURE

TEST/CALIBRATION)

MANUAL SHUT-

OFF VALVE

RSI

PRESSURE

REGULATOR

RSI GAS

VALVE

1/4” NPT PLUG

(INSTALL

MONOMETER HERE

FOR COMBUSTION

CALIBRATION)