Chapter 1, Chapter 2, 9 start sequence – AERCO BMK 1.5 LN July 2011 User Manual

Page 38: Benchmark 1.5ln low nox boiler, Gf-120

CHAPTER 3: CONTROL PANEL OPERATION

Page

38 of 152 PR2: 05/09/12

Benchmark 1.5LN Low NOx Boiler

Operation and Maintenance Manual

OMM-0041_0D

GF-120

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526-0288

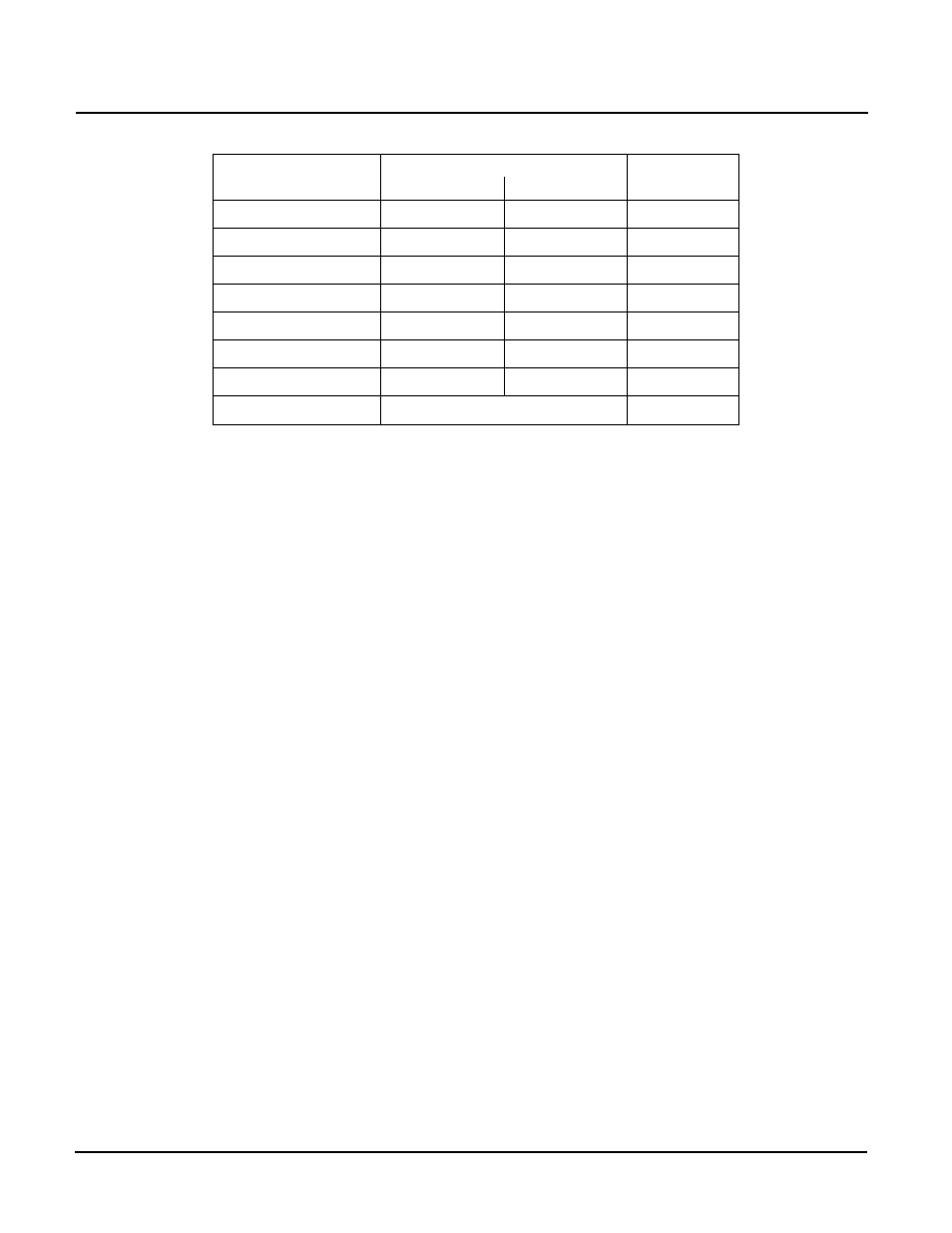

Table 3-6: Combustion Cal Menu

Available Choices or Limits

Menu Item Display

Minimum

Maximum

Default

CAL Voltage 16%

.25

8.20

1.80v

CAL Voltage 30%

.25

8.20

3.20v

CAL Voltage 45%

.25

8.20

3.70v

CAL Voltage 60%

.25

8.20

3.80

CAL Voltage 80%

.25

8.20

4.60

CAL Voltage 100%

.25

8.20

6.00

SET Valve Position

0%

100%

0%

Blower Output

Monitor Blower Output Voltage

.00

2.9 START SEQUENCE

When the Control Box

ON/OFF switch is set to the ON position, it checks all pre-purge safety

switches to ensure they are closed. These switches include:

•

Safety Shut-Off Valve Proof of Closure (POC) switch

•

Low Water Level switch

•

High Water Temperature switch

•

High Gas Pressure switch

•

Low Gas Pressure switch

•

Blower Proof switch

•

Blocked Inlet switch

If all of the above switches are closed, the

READY light above the ON/OFF switch will light and

the unit will be in the Standby mode.

When there is a demand for heat, the following events will occur:

NOTE

If any of the Pre-Purge safety device switches are open,

the appropriate fault message will be displayed. Also, the

appropriate fault messages will be displayed throughout

the start sequence, if the required conditions are not

observed.

1. The DEMAND LED status indicator will light.

2. The unit checks to ensure that the Proof of Closure (POC) switch in the downstream Safety

Shut-Off Valve (SSOV) is closed. See Figure 3-3 for SSOV location.

3. With all required safety device switches closed, a purge cycle will be initiated and the

following events will occur:

a) The Blower relay energizes and turns on blower.

b) The Air/Fuel Valve rotates to the full-open purge position and closes purge position

switch. The dial on the Air/Fuel Valve (Figure 3-4) will read 100 to indicate that it is full-

open (100%).

c) The

VALVE POSITION bargraph will show 100%.