Aerco, Benchmark 1.5ln low nox boiler, Gf-120 – AERCO BMK 1.5 LN July 2011 User Manual

Page 135: Operation and maintenance manual, Legend

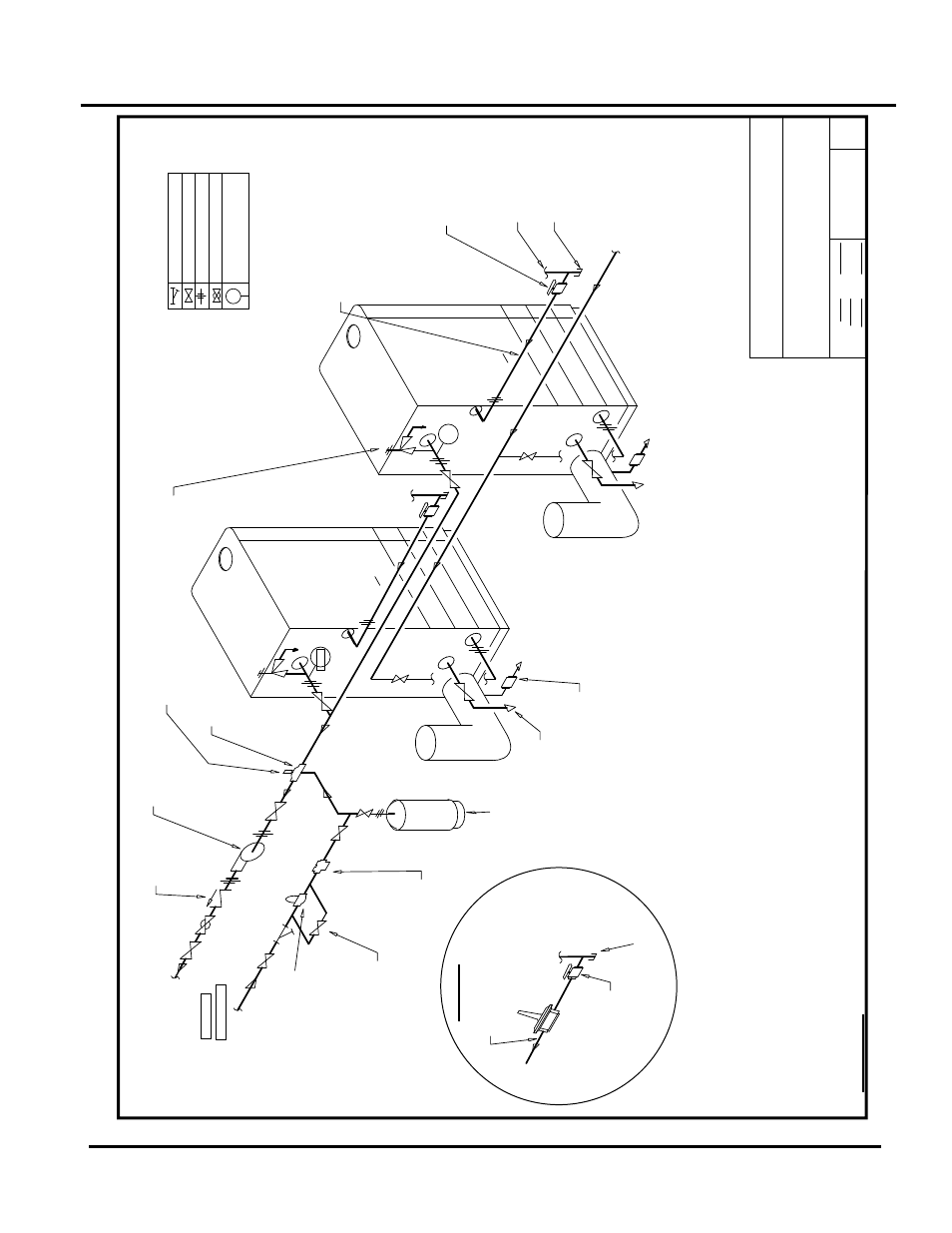

APPENDIX G: PIPING DRAWINGS

PR2: 05/09/12 Page

135 of 152

Benchmark 1.5LN Low NOx Boiler

Operation and Maintenance Manual

OMM-0041_0D

GF-120

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526-0288

5)

THIS IS A TYPICAL INSTALLATION DRAWING

.

LOCAL CODES AND AUTHORITIES SHOULD BE CONSULT

ED

.

CONVENIENT FLOOR DRAIN

.

RELIEF VALVE SHOULD BE PIPED VERTICALLY TO A HEIGHT

18

'' ABOVE FLOOR

.

FITTINGS TO PREVENT INTERFERENCE WITH REMOVAL OF BOILER PANELS AND COVERS

.

ALL PIPING AND

ELECTRIC CONNECTIONS

(SERVICE SWITCHES

, CONDUIT BOXES

) SHOULD LIKEWISE BE

6"

AWAY FROM SIDE PANELS

.

1)

FOR ACTUAL SIZES AND LOCATIONS OF PIPING AND OTHER CONNECTIONS TO THE BOILER

, SEE DIMENSIONAL DRAWING

(AP

-A

-739

).

3)

ALL

(*)

ITEMS ARE INCLUDED SEPARATELY IN SHIPMENT FROM FACTORY

.

NOTES

:

AIR SEPARATOR

AUTOMATIC AIR VENT

1-

1/

2"

NPT

DRAIN CONN

.

LINE SIZE

BYPASS

BACKFLOW PREVENTER

DIAPHRAGM TYPE EXPANSION TANK

WATER

SUPPLY

* CONDENSATE

DRAIN TRAP

P&

T

PRESSURE REDUCING FILL VALVE

CHECK VALVE (TYP

.)

HEATING SYSTEM SUPPLY

SYSTEM PUMP

P&

T

RELIEF

VALVE

(TYP

.)

HEATING SYSTEM RETURN

* 1

-1

/2

" MANUAL

SHUTOFF VALVE

GAS SUPPLY

2)

SHELL DRAIN VALVE AND CONDENSATE DRAIN TRAP SHOULD BE ARRANGED TO PERMIT THE FLUIDS TO DRAIN FREELY

, BY GRAVITY

, TO A

4)

LOCATE WATER INLET AND OUTLET FITTINGS

(i.

e.

UNIONS

, ELBOWS

, ETC

.)

A MINIMUM OF

6''

FROM BOILER

NORTHVALE

, NJ

07647

INTERNATIONAL

, INC

.

APPD

.

DWN

.BY

SCALE

DATE

DATE

JK

NTS

102307

AERCO

SD

-A

-735

TEMPERATURE GAUGE

P&

T

PRESSURE

&

BALANCING VALVE

ISOLATION VALVE UNION

Y STRAINER

LEGEND

BENCHMARK

1.

5

MIL

. BTU LOW NOx

GAS FIRED BOILER

MULTIPLE UNIT INSTALLATION

6)

WHEN AVAILABLE GAS PRESSURE IS GREATER THAN

2.

0

PSIG

, A LOCK

-UP STYLE REGULATOR MUST BE INSTALLED

DOWNSTREAM OF THE

2"

MANUAL SHUTOFF VALVE TO BRING THE GAS PRESSURE DOWN TO

2.

0

PSIG

.

REV

C

AT MAXIMUM BTU

/HR INPUT

,

MAINTAIN MINIMUM GAS PRESSURE AT

4.

0"

W

.C

.

(FM GAS TRAIN

);

4.

2"

W

.C

.(IRI

).

MAX

. GAS PRESSURE

=2

.0

PSIG

.

(SEE NOTE

6)

7)

A GAS REGULATOR IS MANDATORY FOR THE STATE OF MASSACHUSETTS

, REGARDLESS OF SUPPLY PRESSURE

.

SEE DIAGRAM

1

DRIP TRAP

DRIP TRAP

* 1

-1

/2

" MANUAL

SHUTOFF VALVE

MAINTAIN A REGULATED 4.

0"

W

.C

. (

FM

),

4.

2

W

.C

. (

IRI

)

GAS PRESSURE AT MAX BTU

/HR INPUT

GAS SUPPLY

(TO BOILER

)

(SEE NOTE

7)

Diagram

1