KEYENCE EX-V Series User Manual

Page 25

Chapter 2 Quick Guide to Basic Mode Operation

2

15

*

The distance between the sensor head and target should be more than the full scale when the

stripper is in the top dead center position.

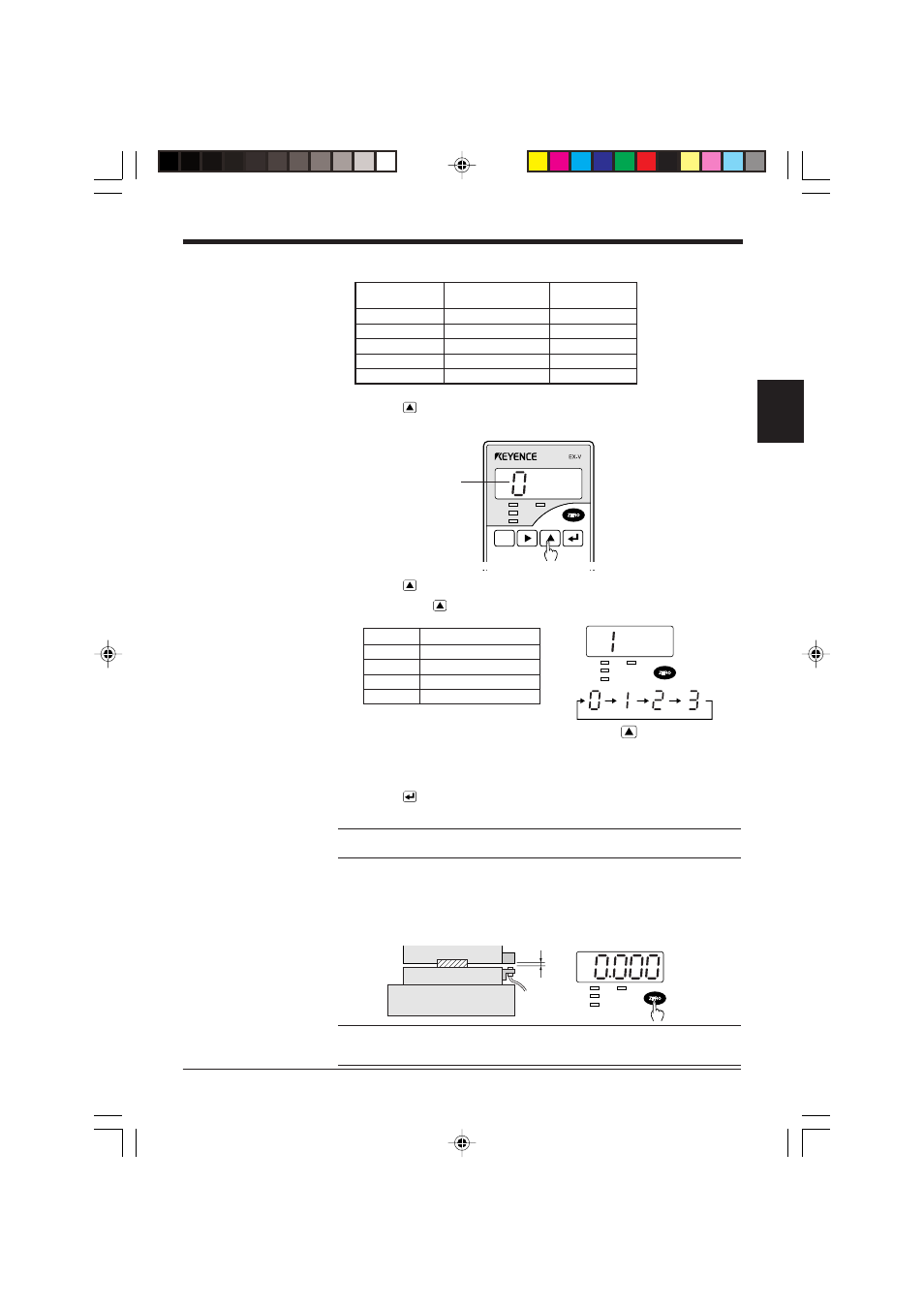

3. Press the

key for at least 2 seconds.

The sensor enters the mode setting state and displays the mode number.

4. Press the

key to display “1” which indicates the “bottom-dead-center” mode.

•

Pressing the

key changes the mode number sequentially.

•

The measurement mode is factory-set to manual.

➮ For the initial setting of each measurement mode, refer to “4.1 Table of Data Processing

Functions” on page 46.

5. Press the

key to save the measurement mode setting.

The sensor returns to the measurement state.

Note: Changing the measurement mode initializes all preset values except for the

tolerance limit values.

6. Activate the machine and check the bottom dead center position during normal

operation. Press the [ZERO] key to set this position as the reference point.

When the [ZERO] key is pressed, “0000” appears on the measured value

display.

Reference: To compensate for the slight variation in the bottom dead center

position at press startup or the influence of temperature fluctuation, refer to “Previ-

ous value comparison function [d]” on page 56.

SET

CALL

HIGH

TIM

GO

LOW

FUNC

UTILITY

MODE

CALIB

Sensor model

Measuring distance

Half scale

(mm) (Full scale)

(mm)

EX-305V

1

0.5

EX-110V

2

1

EX-416V

5

2.5

EX-422V

10

5

EX-614V

4

2

Mode No

HIGH

TIM

GO

LOW

key

Mode No.

Measurement mode

0

Manual

1

Bottom-dead-cente

2

Eccentricity/vibration

3

Thickness/gap

HIGH

TIM

GO

LOW

Stripper or upper die

Die set

Lower die

Normal bottom

dead center