1 measurement modes, 1 bottom-dead-center mode, 2 eccentricity/vibration mode – KEYENCE EX-V Series User Manual

Page 22

Chapter 2 Quick Guide to Basic Mode Operation

2

12

2.1

Measurement Modes

The EX-V series provides the following four measurement modes: "Bottom-dead-

center mode", "Eccentricity/vibration mode", "Thickness/gap mode" (which are

basic modes for quick operation), and "Manual mode" (which allows users to

perform setting as desired). This section explains the major functions of each

mode.

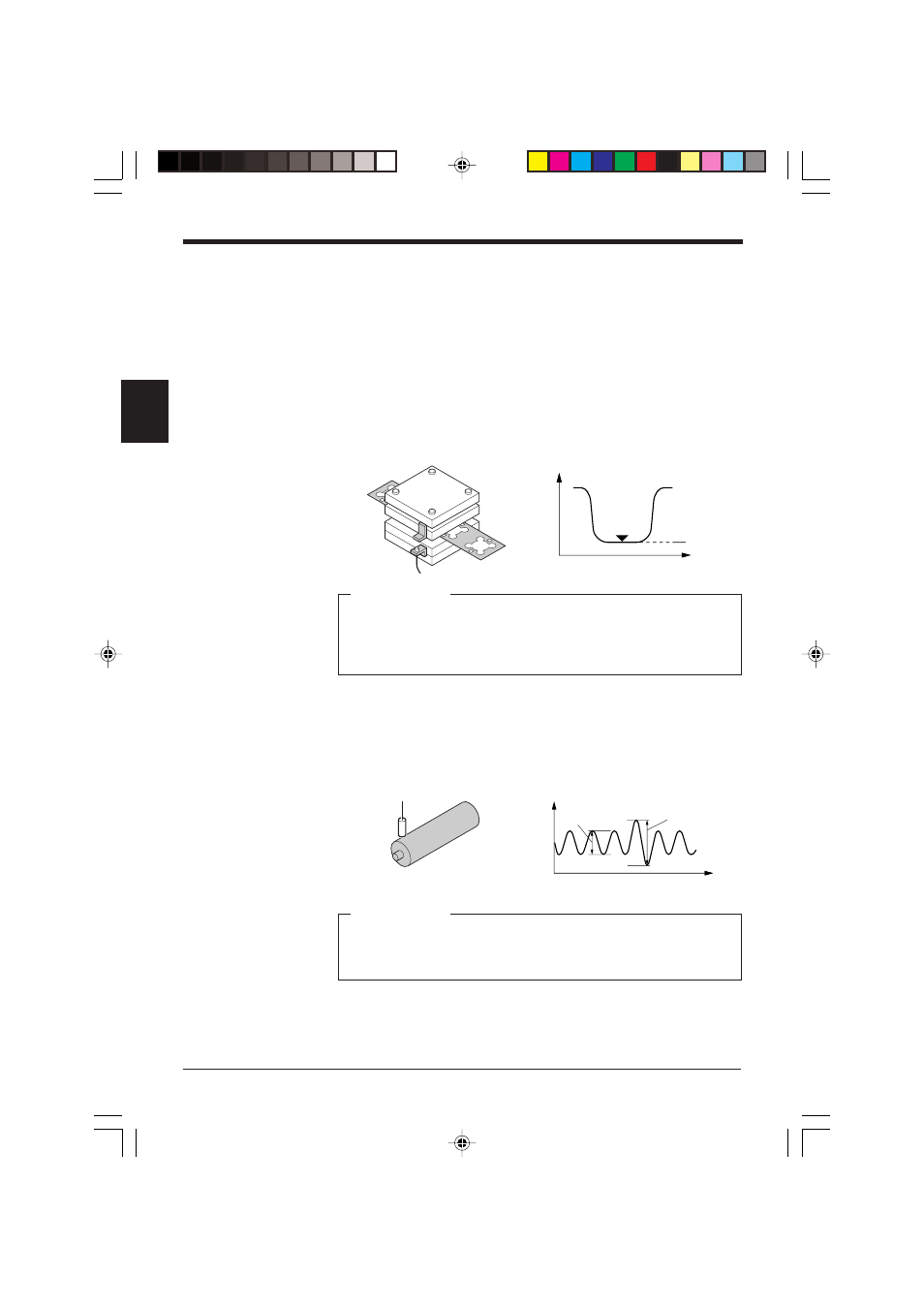

2.1.1 Bottom-dead-center mode

This mode is used to measure the displacement of the origin position of a machine

with stroke movements such as a press. When the displacement of the bottom

dead center or origin position is out of the preset tolerance range, the sensor

outputs an Alarm signal.

Major applications

• Detecting the bottom dead center position of a press

• Detecting the bottom dead center position of a press-fit machine

• Detecting the bottom dead center position of a welding machine

• Pressure control for a injection molding machine

• Measuring the depth of the recess on a piston head

2.1.2 Eccentricity/vibration mode

This mode is used to measure the roller eccentricity or abnormal machine vibration.

When the amplitude of the runout or vibration is larger than the preset tolerance

limit value, the sensor outputs an Alarm signal.

Major applications

• Measuring roller eccentricity

• Measuring surface plate runout

• Detecting runout due to improper chucking

• Measuring drill bit eccentricity

NG

OK

Displacement

Time

Time

Displacement

Bottom dead

center

Displayed value