12 appendix, 1 checklist – Pilz PSENvip RL D P User Manual

Page 145

12.1

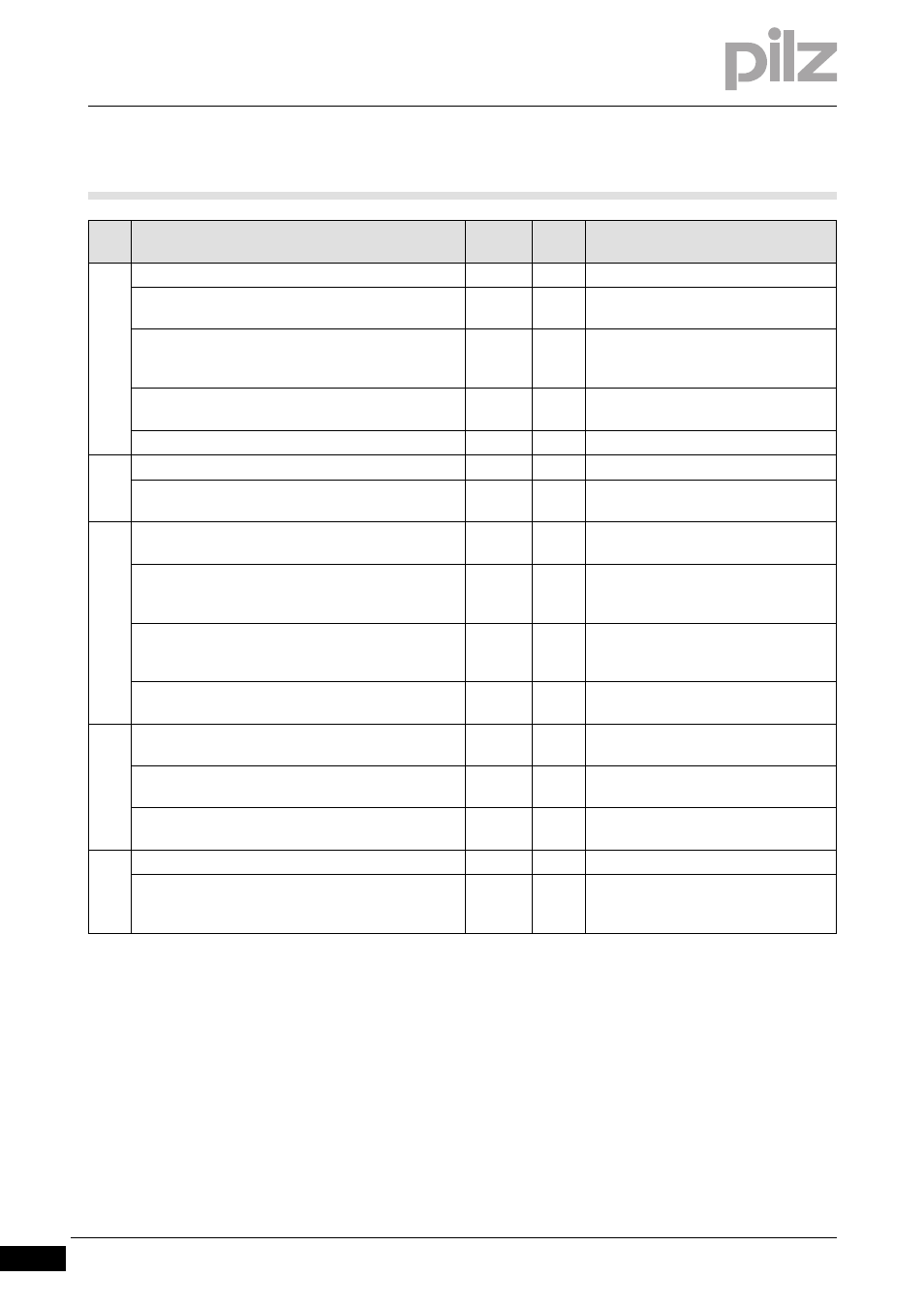

Checklist

12

Appendix

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: [email protected]

12-2

Date: …………………………………………

Signature: ………………………………………………………………

4

Visual inspection

Make sure that there are no objects in the protected

space between the transmitter and receiver.

Make sure that there are no transparent materials

between the transmitter and receiver (e.g. glass

panel).

Are all the mechanical connections to the

PSENvip attached correctly?

Cables are undamaged?

5

Check commissioning

Has the system been commissioned correctly in ac-

cordance with the documentation?

6

Check the circuitry of the programmable safety

and control system

Have the outputs that have been defined as OSSDs

been incorporated in accordance with the required

category?

Are the switching elements that are connected to

the outputs (e.g. valves, contactors) monitored via

feedback loops?

Does the wiring of the inputs and outputs match the

circuit diagram?

7

Check the effectiveness of the PSENvip during

the hazardous movement

Is the PSENvip effective throughout the whole of the

hazardous movement of the plant/machine?

Is the safety function tested in accordance with the

instructions specified in this documentation?

8

Check protected field modes

Do the protected field modes operate in accordance

with the setting of the operating mode selector

switch?

No.

Action

OK

Not

OK

Remarks