Check protective equipment, 1 function test of the safety device, 1 test during initial commissioning – Pilz PSENvip RL D P User Manual

Page 102: 7commissioning, 5 check protective equipment

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: [email protected]

7-21

7.5

Check protective equipment

7

Commissioning

7.5

Check protective equipment

7500

Check protective equipment

7-

Inbetriebnahme_Schutzeinrichtung_pruefen

Tests are used for early identification of defects on the press brake and

its safeguards. They help to maintain a safe, working condition, i.e. to

prevent accidents.

The test of the protective equipment consists of:

A function test using the test piece

and

a visual inspection

Sicherheit_Warnung_Abkantpresse_stilllegen

7.5.1

Function test of the safety device

Function test of the safety device

7-

Inbetriebnahme_Schutzeinrichtung_pruefen_Funjktionspruefung

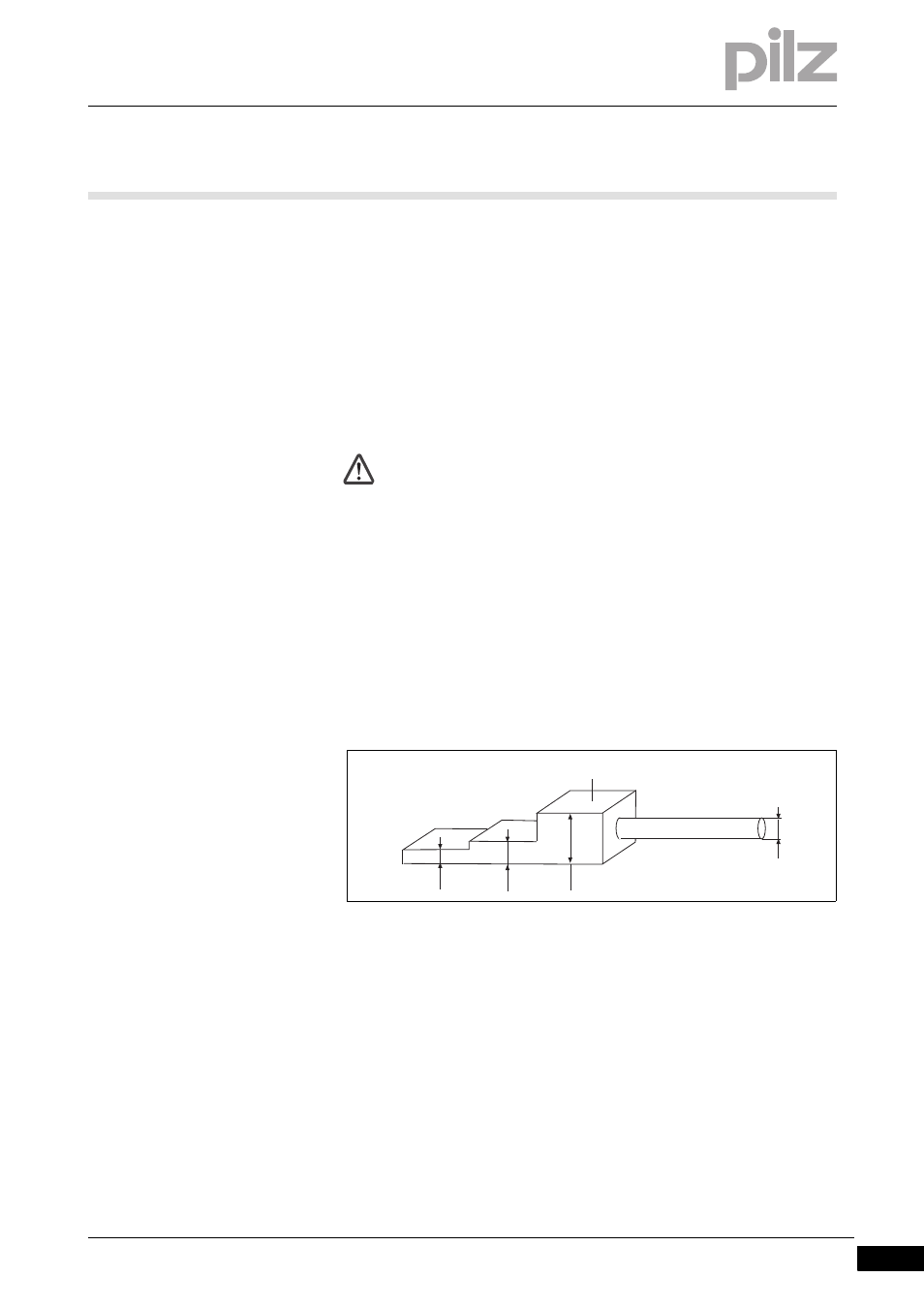

A test piece in accordance with Annex H of EN 12622 is used for the

function test.

Fig. 7-20:

Test piece in accordance with EN 12622

The function test on the protective equipment using the test piece in-

volves:

The detection of objects

Overrun measurement

7.5.1.1

Test during initial commissioning

Test during initial commissioning

7-

Inbetriebnahme_Schutzeinrichtung_pruefen_Funjktionspruefung_Erstinbetriebnahme

The machine manufacturer must perform a function test on the safe-

guard before putting the press brake into service. During this test the

WARNING!

The press brake must be shut down immediately if the test

reveals a fault!

Failure to comply

could result in a hazardous situation, which

could lead to serious injury and death.

In this case, have the safety equipment checked by qualified

staff.

10

15

35

Ø 14

50 x 50