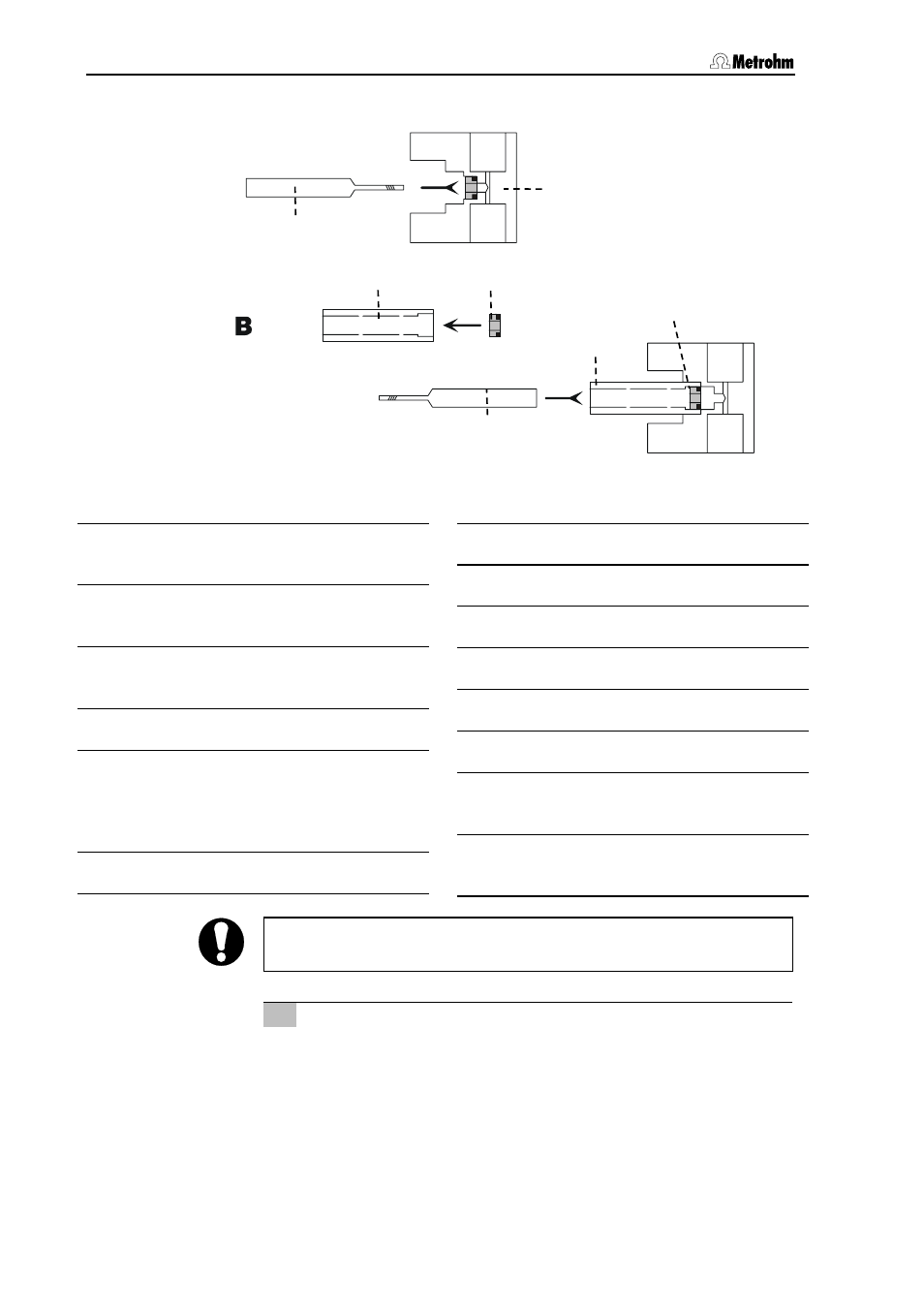

Figure 27, Replacement of the piston seal 140, 136 of – Metrohm 844 UV/VIS Compact IC User Manual

Page 96: On 134, Al 140, Tool 144, 145 is, Tool 145, 145 together with the seal is, 144 (see figure 27

Table of contents

Figure 27: Replacement of the piston seal

54

Pump head 6.2824.040/6.2824.100

133 Screw (3.709.1100) for piston

cartridge

134 Zirconium piston (6.2824.070) with

piston shaft

135 Spring retainer

136 Spring (6.2824.050) for main piston

or

Spring (6.2824.060) for auxiliary

piston

137 Piston cartridge (4.709.0760)

138 Piston guide sleeve (4.709.4380)

139 Piston guide sleeve (4.709.4370)

140 Piston seal (6.2741.020)

141 Inlet valve 6.2824.020/6.2824.090

142 Outlet valve 6.2824.010/6.2824.080

143 Screw holder for valve

144 Special tool (6.2617.010) to remove

145 Special tool (6.2617.010) to install

The seal surface in the pump head

must not be damaged

(avoid contact with tool)!

5 Cleaning/replacement of inlet valve 141 and outlet

valve 142

• Contaminated or blocked valves are cleaned by rinsing with

dist. water, RBS solution or acetone. The rinsing effect can be

reinforced by brief treatment in an ultrasonic bath (max. 20 s;

if longer the sapphire sphere of the valve can be damaged).

• If this does not have the desired effect, the valves can be

disassembled as shown in Figure 28. The valve components

are pushed out with the aid of a syringe needle inserted

A

C

144

145

140

27/54

144

145

140