Planned certified configurations, Safety manual (aadvance controller) – Rockwell Automation AADvance Controller Safety Manual User Manual

Page 48

3-14

Document: 553630

ICSTT-RM446K-EN-P Issue: 10

_C

Safety Manual (AADvance Controller)

Planned Certified Configurations

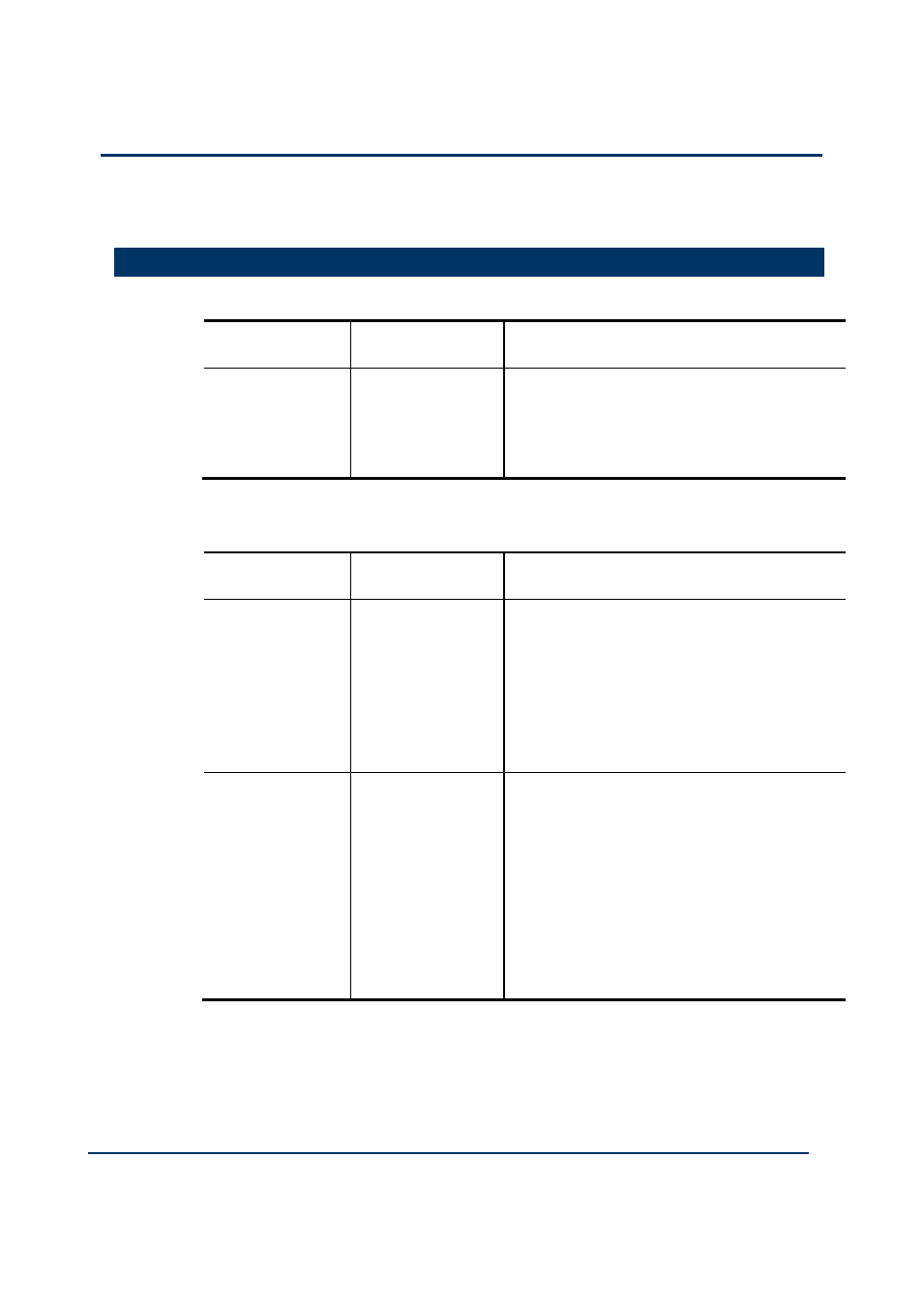

Table 10:

Central Modules

Modules

TÜV Certified

Configuration

Conditions

Processor Module

T9110

1oo1D, 1oo2D,

2oo3D

Safety-related and can be used for safety-critical

applications in SIL2 with 1 module fitted and SIL3

applications with 2 or 3 modules fitted.

Note: For High Demand applications you must use

a minimum of two processors.

Table 11:

Input Modules

Modules

TÜV Certified

Configuration

Conditions

Digital Inputs

T9401/2, 24V dc,

8/16 Channel,

isolated.

+

T9801/2/3 Digital

Input TA, 16 channel,

Simplex/Dual/TMR

1oo1D, 1oo2D,

2oo3D

De-energized to action (normally energized): SIL3

with 1, 2 or 3 modules fitted.

Energize to action (normally de-energized): with 1, 2

or 3 modules fitted

Note: when the integrity level is at 1oo1D then the

faulty module must be replaced to restore the

integrity level back to 1oo2D.

Analogue Inputs

T9431/2, 8/16

Channel, isolated

+

T9831/2/3 Analogue

Input TA, 16

Channel,

Simplex/Dual/TMR

1oo1D, 1oo2D,

2oo3D

Within the manufactures specified safety accuracy

limits of 1%. The safety state of the analogue input

has to be set to a safe value which is a calculated

value based on a count value of 0mA. (refer to the

AADvance Configuration Guide Doc no: 553633 for

more details)

SIL3 with 1, 2 or 3 modules fitted.

Note: when the integrity level is at 1oo1D then the

faulty module must be replaced within the MTTR

assumed for the PFD calculations to restore the

integrity level back to 1oo2D.