Rockwell Automation SP200 AC Drive, 1 2 Channel Analog, Preset Speed User Manual

Page 33

Editing Drive Parameters

7-11

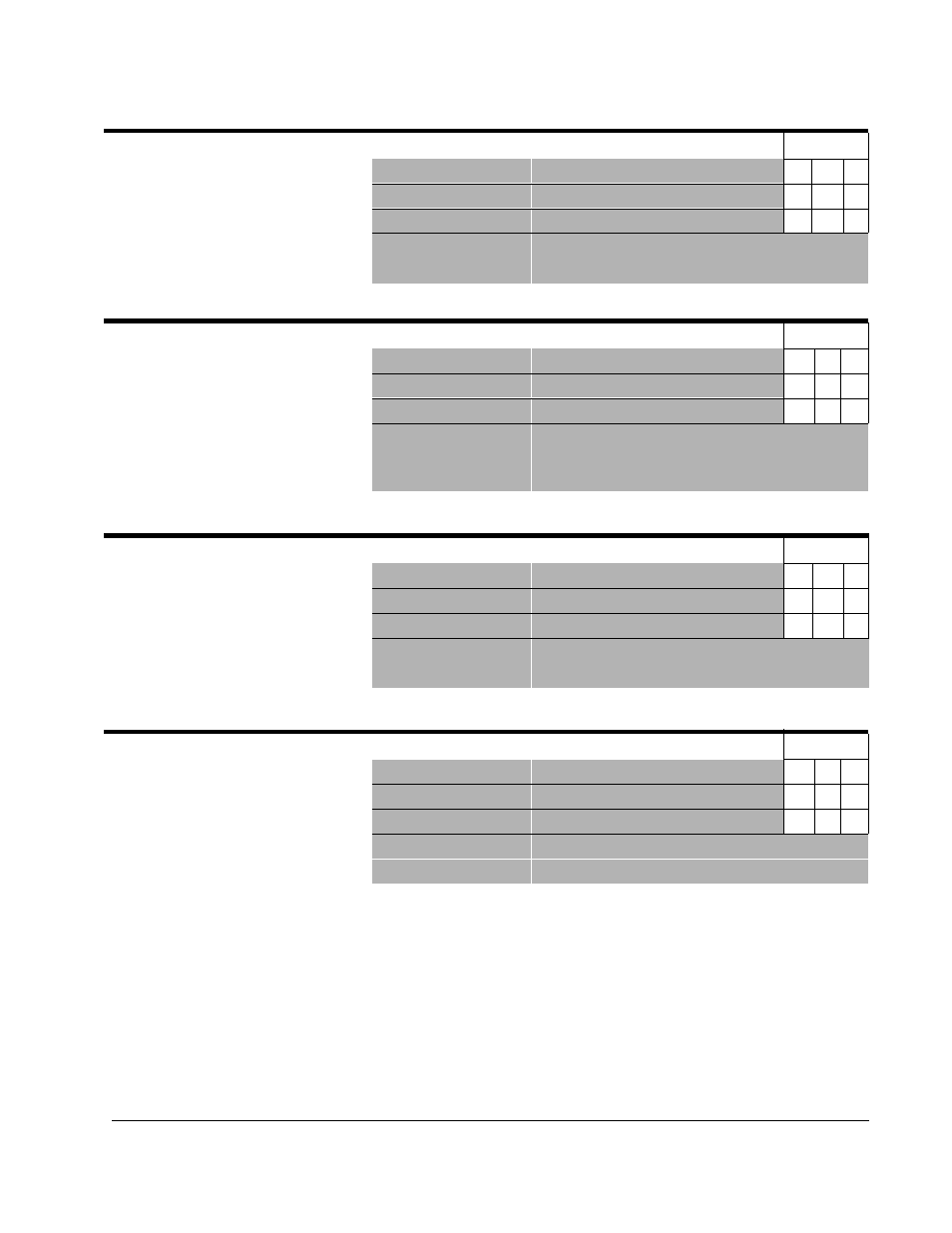

P-23 Analog Input 1 Gain

Model

A

B

C

When using analog input 1 for a

speed reference, use this parameter

to set the level of the analog input

used to command Maximum Speed

(P-01).

Parameter Range:

0.0 to 110.0 (x.x%)

X

X

Default Setting:

100.0

X

X

Running Access:

RW

P-24 Analog Input 2 Offset

Model

A

B

C

When using analog input 2 for a

speed reference, use this parameter

to set the level of the analog input

used to command Minimum Speed

(P-00).

Parameter Range:

0.0 to 110.0 (x.x%)

X

Default Setting:

0.0

X

Running Access:

RW

P-25 Analog Input 2 Gain

Model

A

B

C

When using analog input 2 for a

speed reference, use this parameter

to set the level of the analog input

used to command Maximum Speed

(P-01).

Parameter Range:

0.0 to 110.0 (x.x%)

X

Default Setting:

100.0

X

Running Access:

RW

P-26 Process Proportional Gain

Model

A

B

C

Use this parameter to specify the

proportional gain (Ki) for the closed

loop process PI controller. It is used

only when P-29 (Process Operation)

is set to 2 or 3 to select PI control or

Parameter Range:

0 to 10.0 (x.x decimal)

X

Default Setting:

0

X

Running Access:

RW

inverted PI control. This parameter is scaled so that when it is set to 1.0, the process response is 1 Hz when

the process error is 1 Hz. The correct value for this parameter depends on the dynamics of the process being

controlled, as well as the desired response.