Identifying fault codes and recovering, 2 identifying fault codes and recovering – Rockwell Automation GV3000/SE AC Gen. Purpose and Vector Drive Software Start-Up and Ref. Manual User Manual

Page 179

Troubleshooting the Drive Using Error Codes

5-3

5.2 Identifying Fault Codes and Recovering

GV3000/SE drive fault codes are shown in table 5.2. To clear a single fault that has

occurred so that the drive can be started again, correct any problems indicated by the

fault code and press the STOP/RESET key on the keypad, or assert the fault reset

from the selected control source (P.000). Because multiple faults can occur and only

the first will be displayed, you must access the error log in order to view all of the faults

that have occurred. See section 5.3 for instructions on how to view the error log.s

!

ATTENTION: DC bus capacitors retain hazardous voltages after input

power has been disconnected. After disconnecting input power, wait five

(5) minutes for the DC bus capacitors to discharge and then check the

voltage with a voltmeter to ensure the DC bus capacitors are discharged

before touching any internal components. Failure to observe this

precaution could result in severe bodily injury or loss of life.

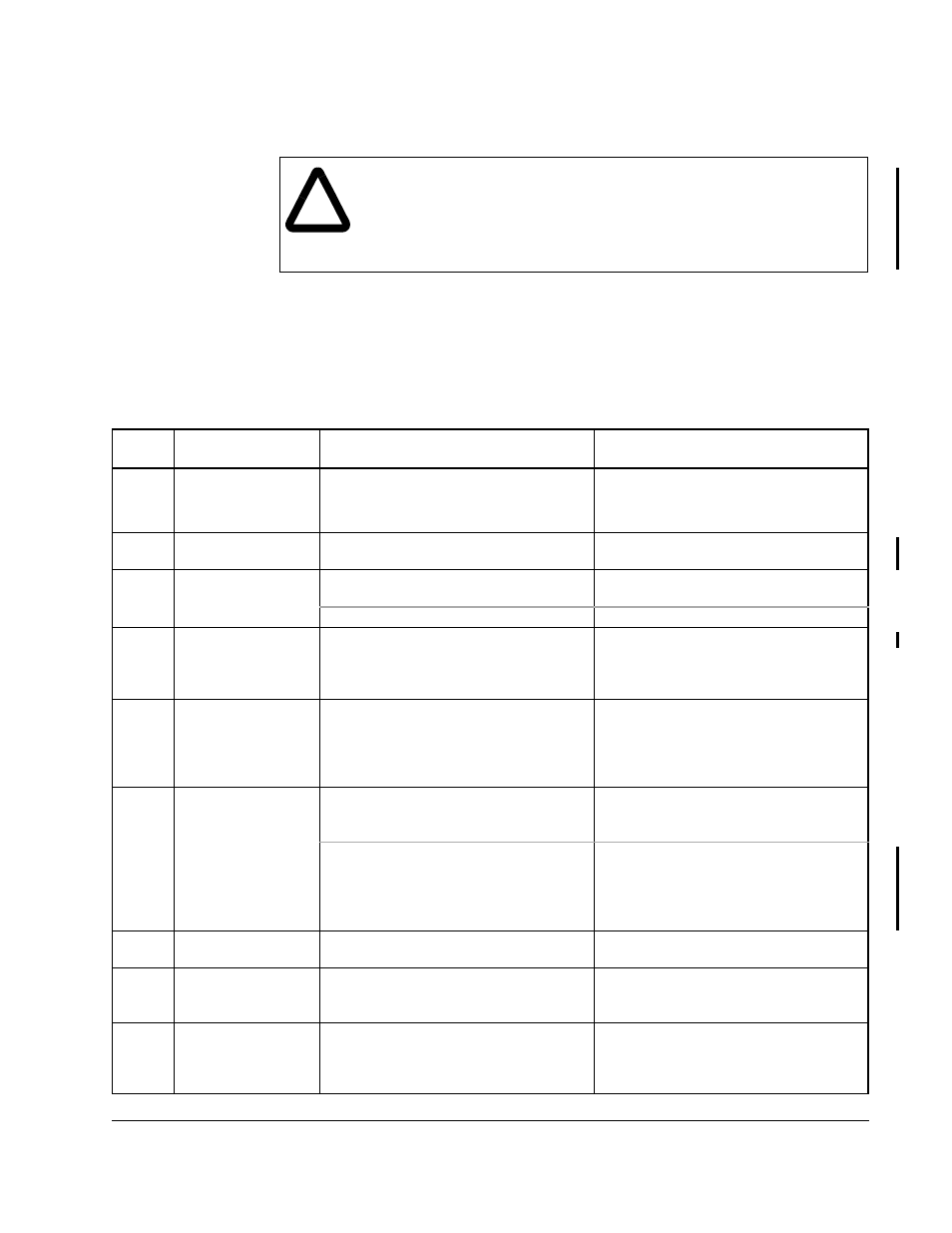

Table 5.2 – List of Fault Codes

Code

Fault

Description

Fault Cause

Corrective Action

AIn

Analog input signal

loss

P.011 = 4 or 5 and 4 to 20 mA analog

input is below 2 mA.

Verify that P.011 is set correctly.

Check that the analog input source

supply

≥ 4 mA.

bYC

Incorrect precharge

status

Precharge initiated and incorrect

precharge status is returned.

Check the operation of the precharge.

CHS

Default parameter

restore (checksum

error)

During drive operation:

Regulator board failure.

Contact Reliance or replace Regulator

board.

After Regulator board replacement:

Contact Reliance.

EC

Earth current failure

(ground fault)

Unintentional grounding of the output. Check isolation between ground and

output terminals. Possible leakage,

current sensor defects; replace

sensor.

EEr

Non-volatile

memory write

failure

Failure on write to non-volatile

memory.

Connect CS3000 software to upload

parameters or record by hand. Then

replace Regulator board. Parameter

values will be lost when power is

cycled.

EL

Encoder loss

Drive is not detecting feedback from

the encoder.

Check the connection between the

encoder and the drive. Check the

encoder/motor coupling.

For SVC operation, conditions exist for

more than 5 seconds that may result in

an inability to complete a ramp-to-rest

stop.

For SVC operation, check motor data

parameters. Check U.006. Incorrect

magnetizing current may be generated

by performing self-tuning with a load

connected to the motor.

FL

Function loss

Function loss input on control terminal

is opened.

Check external interlocks at terminals

16, 20.

HId

High time

identification

aborted

Identification process for V/Hz has

been aborted.

See H.019 for identification result.

HIL

High line voltage

Input voltage more than 15% above

nominal. (Note that this is not tested

for in 1-150 HP Power Modules

configured for vector control.)

Check actual line voltage against

U.018 or H.021.