Interpreting modulećtoćplc data (reads) chapter 6, Status word 2 (words 3 and 7), Figure 6.4 status word 2 – Rockwell Automation 1771-QB Linear Pos. User Manual

Page 68

Interpreting ModuleĆtoĆPLC Data

(READS)

Chapter 6

6Ć7

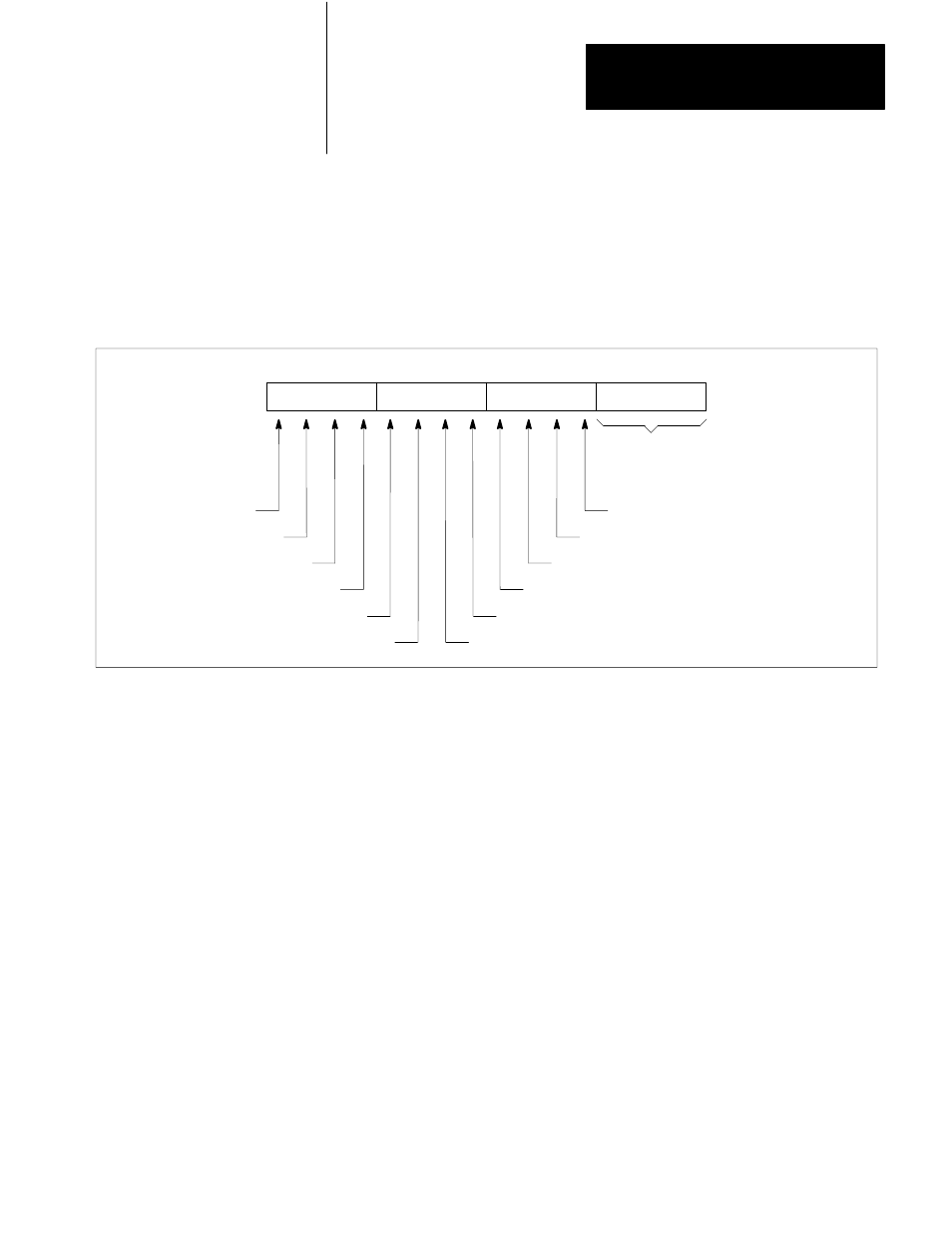

Status Word 2 (words 3 and 7)

Status word 2 gives the active setpoint and provides additional status

information.

Figure 6.4

Status Word 2

50053

15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00

0

..

.

..

.

...

..

.

..

.

...

..

.

..

.

...

..

.

..

.

...

..

.

..

.

...

..

.

..

.

...

..

.

..

.

...

..

.

..

.

...

..

.

..

.

...

..

.

..

.

...

..

.

..

.

...

..

.

..

.

...

Reserved

Error valid

Position valid

Diagnostic valid

Setpoint Number,

binary format (0Ć13),

(15 Ć a motion segment

is active)

Integral limit reached

Excess following error

PID error

Immediate stop

Discrete fault

Feedback fault

Analog fault

Internal fault

Bits 0 to 3 – Setpoint Number

Bits 0 to 3 give the currently active setpoint (1 to 13 in binary format), or

indicate that a motion segment is active (15 binary). This parameter defaults to

zero on powerup or after a jog command. It then remains zero until a setpoint or

motion start is received and accepted.

The currently active setpoint is the target point of the latest initiated axis move.

If hardware started is enabled, the module won’t update the setpoint number to a

commanded setpoint until after it receives a hardware start.

Bit 4 – Reserved

Bit 4 is reserved for future use.

Bit 5 – Error Valid

The error valid bit is on if the next two status block words (i.e., words 4 and 5

for axis 1 and words 8 and 9 for axis 2) for this axis contain a valid following

error value.