System overview – Rockwell Automation 1771-QB Linear Pos. User Manual

Page 15

Introducing the Linear Positioning Module

Chapter 1

1Ć4

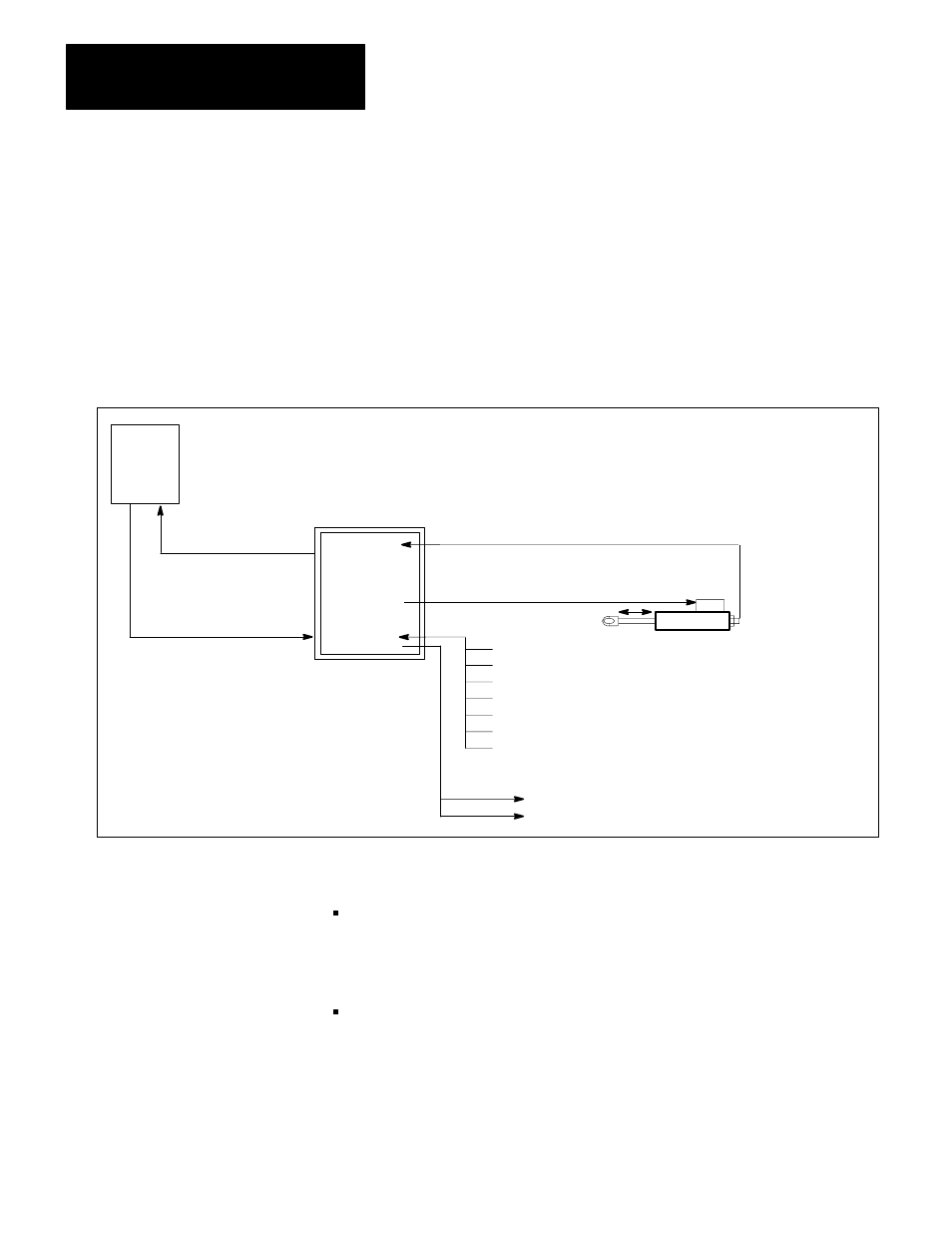

Figure 1.2 shows one of the module’s two control loops within a linear

positioning system for closed-loop axis control. The module communicates with

a programmable controller through the 1771 backplane.

The programmable logic controller sends commands and user-programmed data

from the data table to the module as directed by a block-transfer write

instruction.

Figure 1.2

System Overview

50033

PLC

Processor

Linear

Positioning

Module

D

Status Block

D

Parameter Block

D

Setpoint Block

D

Motion Block

D

Command Block

D

Jog Forward

D

Jog Reverse

D

Hardware Start

D

Auto/Manual

D

Hardware Stop

D

Input 1

D

Input 2

Linear Displacement

Transducer

D

Output 1

D

Output 2

Discrete Outputs

D

Discrete Inputs

Transducer

Analog Output

Servo Valve

PistonĆType

Cylinder

NOTE: All inputs and outputs are

duplicated for the second axis.

Interface

Using PLC programming, you can:

send configuration and control parameters to the module via parameter,

setpoint, motion, and command blocks. With this data the module determines

axis parameters, calculates velocity curves, and commands axis

end-positions. (See Chapters 7 and 9.)

read status blocks to monitor axis position and status indicators in your

process control system. (See Chapter 6.)

The module’s analog outputs (one for each control loop) connect to servo or

proportional valves via wiring arm terminals. The module controls speed and

position by adjusting the voltage or current levels of the analog outputs 500

times each second.

System Overview