Rockwell Automation 1772-LS_LSP,D17726.8.6 PROG/OPER MANUAL-MINI PLC-2/05 User Manual

Page 50

Scan Theory

Chapter 5

5Ć3

On power-up, the processor begins the scan sequence with the I/O scan. Data

from output image table is written to the output modules. Data from the input

modules is read into the input image table.

Next, the processor scans the program statement by statement:

1.

For each condition, the processor checks, or “reads,” the image table to see

if the condition has been met.

2.

If the set of conditions has been met, the processor writes a one into the bit

location in the output image table corresponding to the output terminal to

be energized. On the other hand, if the set of conditions has not been met,

the processor writes a zero into that bit location, indicating that the output

terminal should not be energized.

Important: When your processor is in the remote test mode, all outputs are

held off. When your processor is in the run/program mode, all outputs are

controlled by the user program.

Average scan time is the average amount of time it takes the processor to

monitor and update input and outputs, and to execute instructions in the

program. The scan is performed serially; first the I/O image table is updated,

(other parts of the data table are not scanned), then the user program is scanned.

There are two ways to measure average scan time:

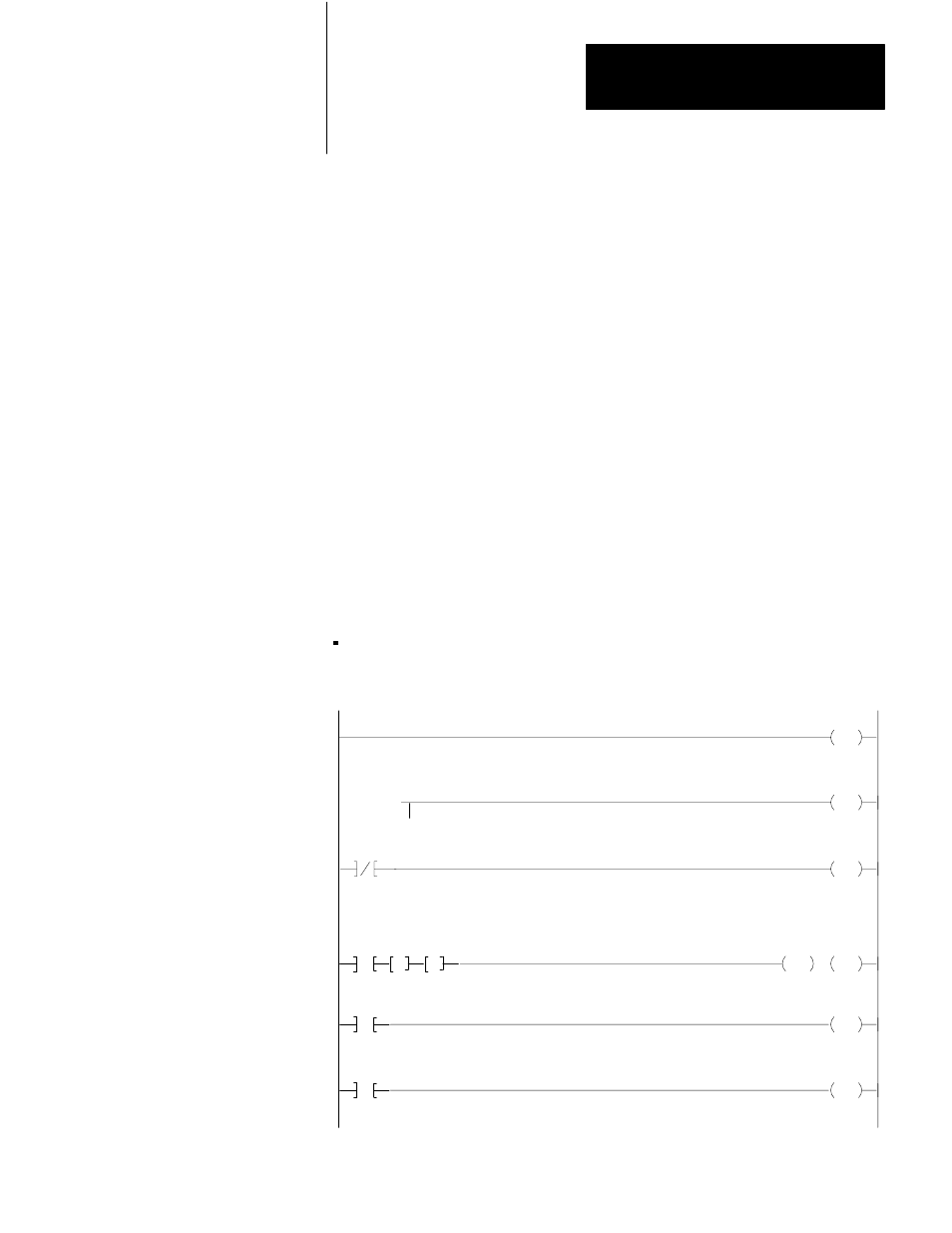

Append the rungs in Figure 5.2 to your program.

Figure 5.2

Average Scan Time

031

14

CTU

031

PR 999

031

14

CTU

031

PR 999

RTO

032

0.1

032

000

Store

010

G

G

:

Store

000

AC 000

AC 000

PR 999

AC 000

1

031

14

RTR

032

PR 999

:

Store

000 .

2

3

AC 000

031

14

RTR

032

PR 999

AC 000

Rung 1

Rung 2

Rung 3

Rung 4

Rung 5

Rung 6

Average Scan Time