If zero algorithm=1 – MTS SWIFT 20 Ultra Sensor User Manual

Page 90

SWIFT 20 Sensors

90

Test Track Vehicle for Slip Ring Sensor

Installing the Transducer

I.

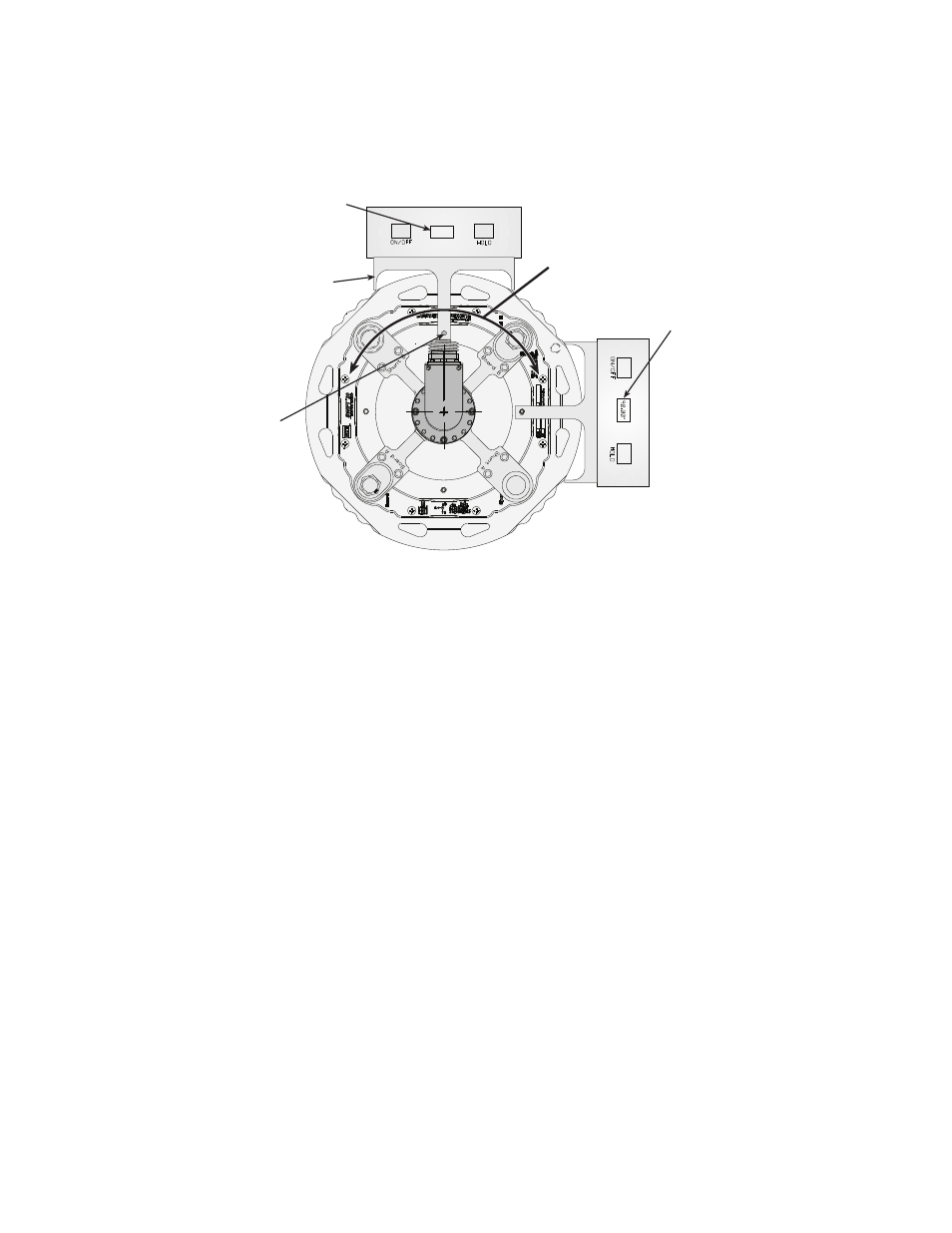

Place the digital inclinometer on the bracket and rotate the tire until the

inclinometer reads 0.0°, ±0.1° (or 90.0°, ±0.1° if the alternate position

is used).

J.

Push the Angle Zero button on the front of the TI box. The Angle Zero

indicator will light for a few seconds, then both the Bridge Zero and

Angle Zero indicators should turn off.

Note

If the red Fail indicator lights momentarily and the Bridge Zero and

Angle Zero indicators end up blinking slowly, problems were detected

with the zero. Try repeating the procedure. Use TISTATUS for a more

detailed explanation of the problem. If you continue to have an error,

consult the chapter

K.

Rotate the transducer slightly to update the rotational transformation.

At this point the TI should be reading absolute forces in the vehicle

coordinate system.

L.

Perform

, “Verifying the Quality of the Zero Procedure,”

M. Look at your data acquisition system to verify that the SWIFT sensor is

gathering data.

If Zero Algorithm=1

When you zero the TI, you want the vehicle to be fairly level and the transducer

to be as close to plumb as practical.

1. Install the SWIFT sensor(s) and data collection equipment on the vehicle.

2. Connect all cables and turn on the power to the TI boxes.

3. Let the TI boxes and transducers warm up for 15-20 minutes.

Digital Inclinometer

(alternate location)

in this position

should read 90°, ±0.1°

Digital Inclinometer

in this position

should read 0°, ±0.1°

Insert Lock Pin in

Pilot Hole

Level Bracket

S20-23

0.00°

Rotate

Transducer

+ or 90°