Importance of bolts, Before you begin – MTS SWIFT 20 Ultra Sensor User Manual

Page 75

Test Track Vehicle for Slip Ring Sensor

SWIFT 20 Sensors

Installing the Transducer

75

•

12 V power supply (for example, a car battery)

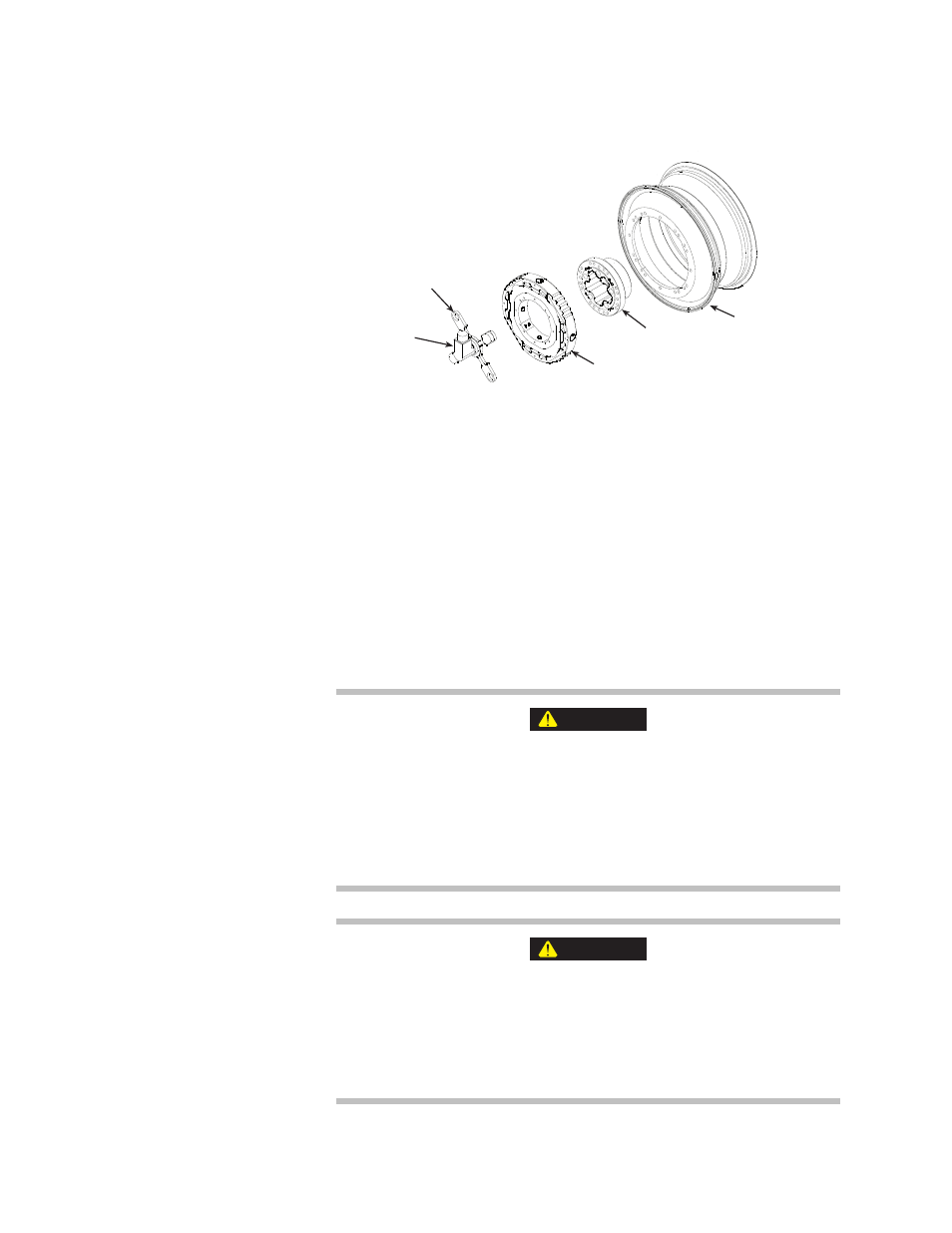

Slip Ring Installation Components (Test Track)

Importance of bolts

Bolts provide exceptional clamp force at the transducer to rim/spindle interface.

•

Bolts on the inner hub secure the hub adapter to the SWIFT sensor.

•

Bolts on the outer ring secure the SWIFT sensor to the wheel rim (or road

simulator spindle adapter).

Note

Make sure all bolts are in place and fully torqued during all tests.

Correct use of bolts reduces the safety hazard and ensures optimal

transducer performance.

Before you begin

Observe the following safety conditions while you are attaching the SWIFT

sensor and components to the vehicle.

Do not pressure-wash the transducer or clean it with solvents that would

degrade its silastic seal.

Pressure-washing the transducer or cleaning it with certain solvents can

damage it or degrade its silastic seal.

Avoid pressure-washing the transducer. Use only solvents that will not degrade

the silastic seal.

Do not use high-pressure-air to clean debris from around the transducer

connectors.

High-pressure-air can damage the silastic seals.

Use a fine wire brush and low air-pressure [0.07 MPa (10 psi)] to clean debris

from around the transducer connectors.

S20-57

Modified Rim

Hub Adapter

Transducer

Slip Ring

Bracket

Slip Ring

Encoder

CAUTION

CAUTION