Coordinate system, Coordinate system 23 – MTS SWIFT 20 Ultra Sensor User Manual

Page 23

Coordinate System

SWIFT 20 Sensors

Hardware Overview

23

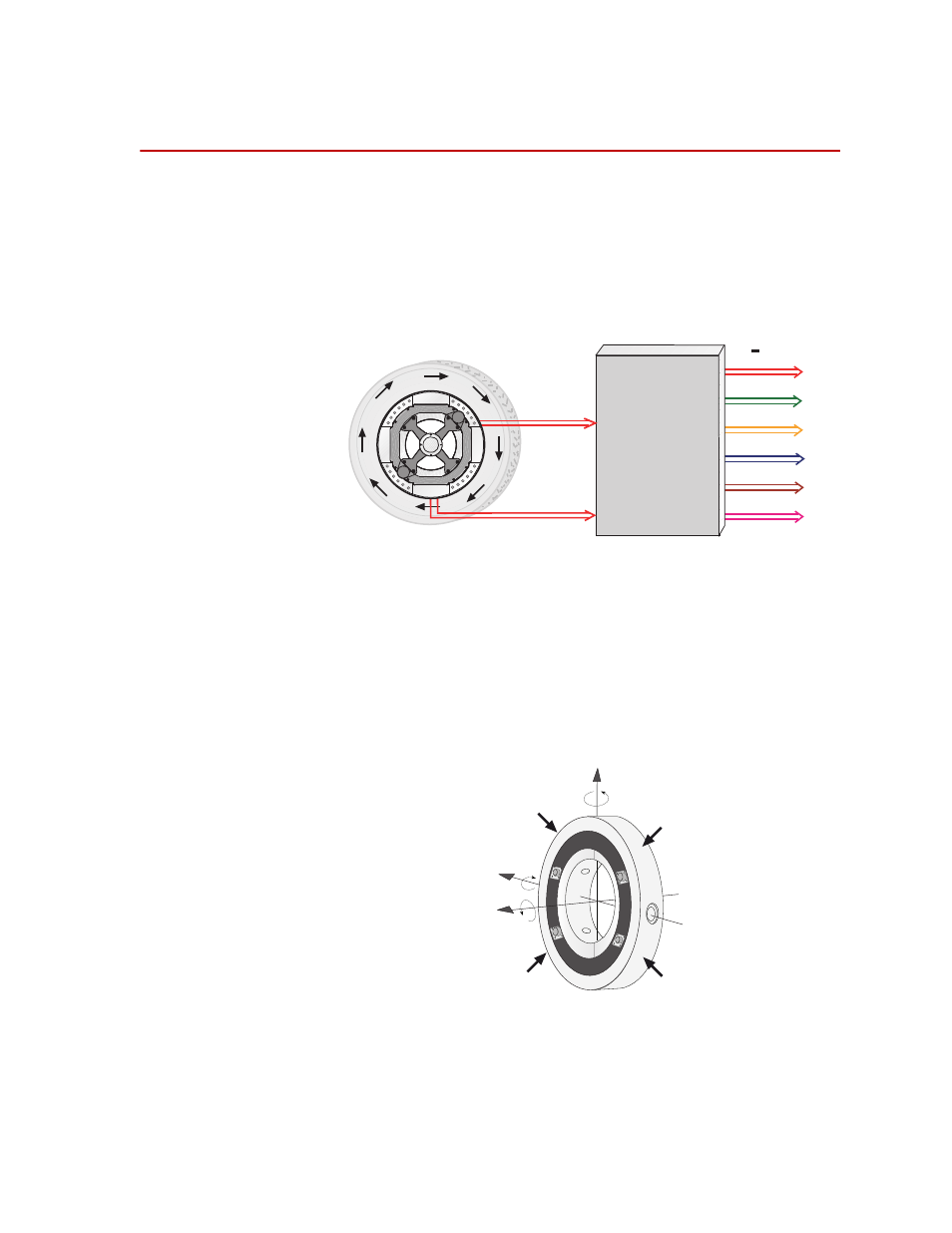

Coordinate System

In the transducer, independent strain gage bridges measure forces and moments

about three orthogonal axes. The signals are amplified to reduce the signal-to-

noise ratio. An encoder signal indicates angular position, which is used to

convert raw force and moment data from the rotating transducer to a vehicle-

based coordinate system. The force and moment and encoder information is sent

to the transducer interface (TI).

The TI performs cross talk compensation and converts the rotating force and

moment data to a vehicle coordinate system. The result is six forces and moments

that are measured at the spindle: Fx, Fy, Fz, Mx, My, and Mz. A seventh (angle)

output is available for tire uniformity information, angular position, or to

determine wheel speed (depending on the data acquisition configuration).

The coordinate system shown below was originally loaded into the TI settings by

MTS. It uses the right-hand rule.

The SWIFT coordinate system is transducer-based, with the origin located at the

center of the transducer. The lateral offset of the transducer is illustrated in the

reference drawings at the end of this manual. Positive loads are defined as

applied to the outer ring of the transducer.

Fx

Fy

Fz

Mz

Mx

My

Transducer

Interface

Output signals

+ 10 Volts

Angular

Position

Bridge

Outputs

S20-06

+Mz

+Fz

+Fy

+My

+Mx

+Fx

Forces acting on outer ring

S20-07