MTS SWIFT 20 Ultra Sensor User Manual

Page 88

SWIFT 20 Sensors

88

Test Track Vehicle for Slip Ring Sensor

Installing the Transducer

A.

Download the spinning calibration file (xxxxxs.cal) to the computer

from the MTS Disk that corresponds to the serial number of the

transducer that you are setting up.

B.

If necessary, modify the zero algorithm and angle mode to fit the

application/use requirements as described in

C.

The EncoderSize parameter should be omitted or set to EncoderSize=1

D.

Download the calibration file to the TI box.

Note

If it becomes necessary to change the zero algorithm or angle mode

after downloading the file to the TI, you can do so by using the

TISETZERO utility, as described in

Transducer Interface Set Zero Method,”

6. Elevate the vehicle with a lift, raise each corner with a jack.

7. Perform the zero procedure on each corner of the vehicle.

Use a digital inclinometer to zero the angle and strain gage bridges on the

transducer.

A.

Rotate the tire one full revolution so that the encoder can find the zero

index mark.

Note

The encoder has a red dot on the mounting flange connected to the slip-

ring bracket and a black dot on the slip-ring connector housing where it

interfaces with the mounting flange. These dots, when aligned next to

each other, indicate the index mark is under the encoder sensor.

B.

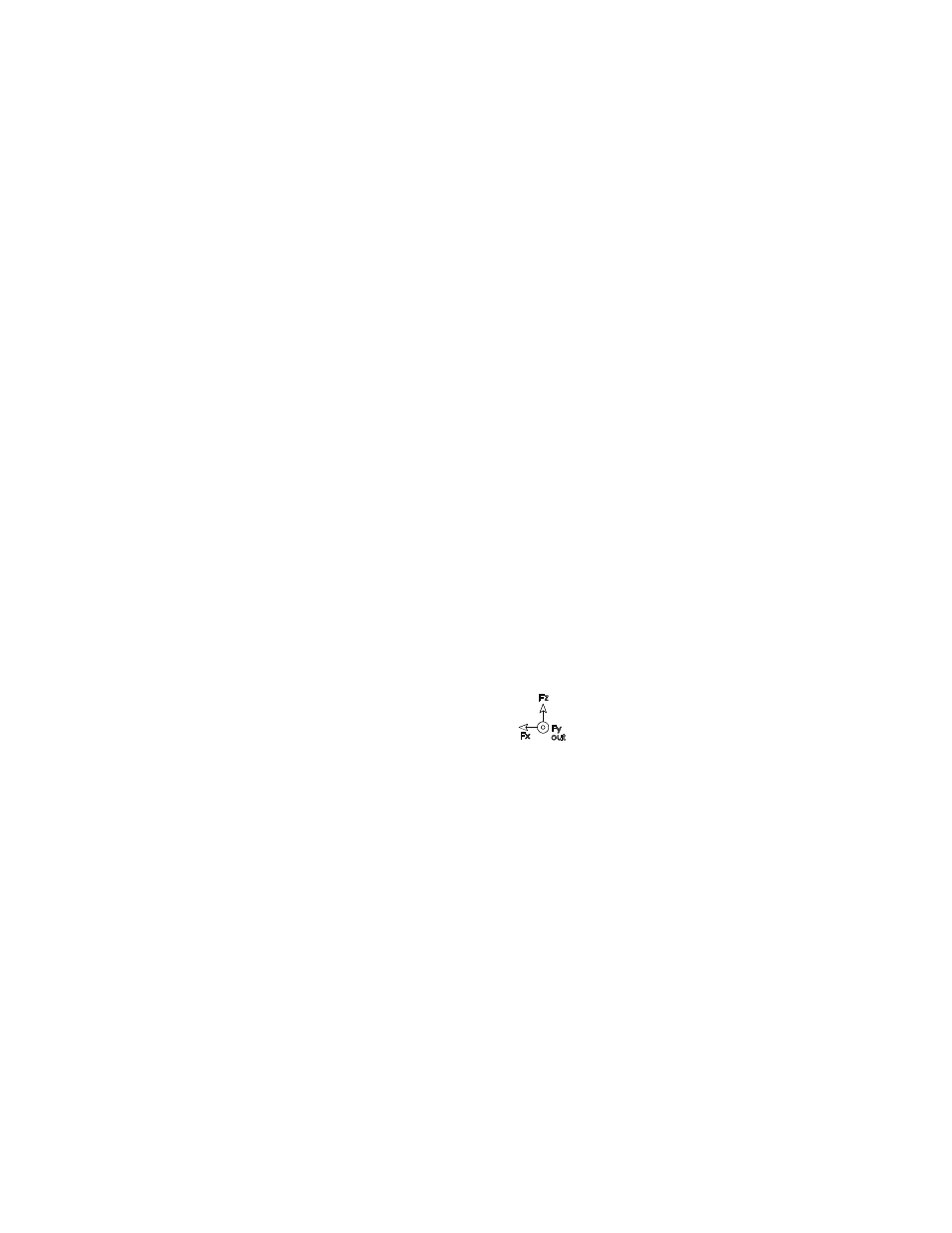

Rotate the tire as necessary, until the Fz on the axes icon (see the next

figure) printed on the transducer label is pointing up

C.

Attach the level bracket so that it sits on top of the transducer. Insert the

locking pin through the bracket and into the pin pilot hole on the

transducer (see the next figure).

Axes Icon

S20-22