Ilar to, Figure 3-11 – INFICON Composer Gas Concentration Controller User Manual

Page 89

3 - 27

IP

N 07

4-

28

9L

Composer Operating Manual

21

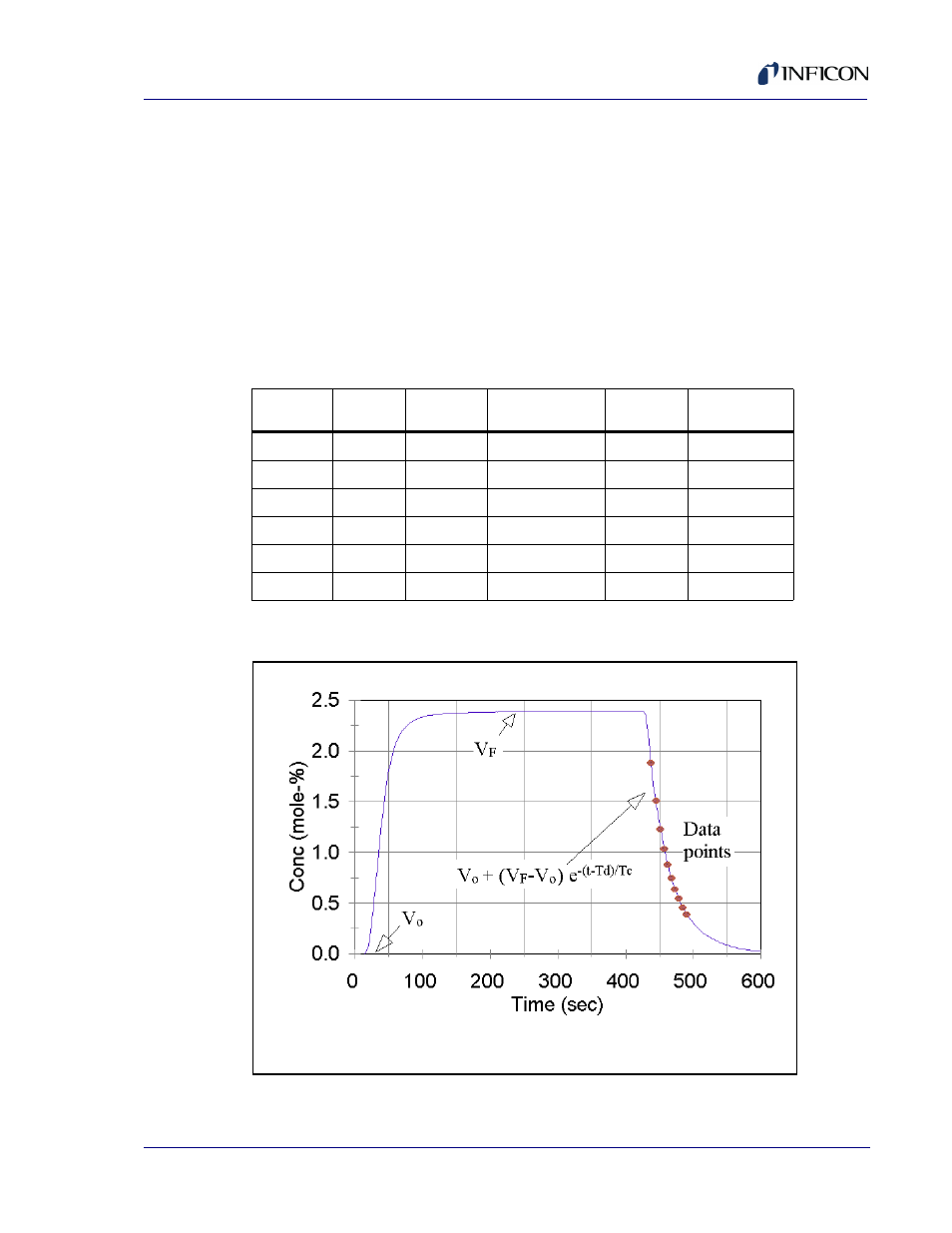

Use linear regression technique to fit data to Y(t) = A + Bt. Then, by

comparing with the above equation, we get Tc = 1/B and Td = -A/B. Thus,

Kp, Tc and Td completely characterize the process under consideration.

The same technique can be used to extract these parameters at an expected

set point, slightly above and slightly below the set point. The average of these

parameters will then be more representative of the dynamics of the process. It

is noteworthy that, in a solid source bubbler like TMIn, the process gain will

gradually diminish with increased flow. The entire procedure of tuning may take

5-30 minutes, depending upon the process. The following table shows some

representative results (nitrogen in hydrogen gas).

Figure 3-11 Concentration transitions during the tuning process. Data points for process

characterization are taken from the decay portion of the cycle.

Table 3-6 Tuning Representative Results (Nitrogen in Hydrogen Gas)

Total Flow

(sccm)

Pressure

(Torr)

Flow

conserved

Process Gain

Kp (mole-%/volt)

Dead Time

Td (sec)

Time Constant

Tc (sec)

400

120

Yes

0.49

2.2

11.3

300

150

Yes

0.65

4.2

14.8

100

200

No

0.95

8.1

22.8

200

300

Yes

0.96

9.8

34.8

200

600

Yes

0.95

17.1

68.8

100

600

Yes

1.89

38.4

113.5