2 measuring the speed of sound, Λm γ λ – INFICON Composer Gas Concentration Controller User Manual

Page 46

2 - 4

IP

N 07

4-

28

9L

Composer Operating Manual

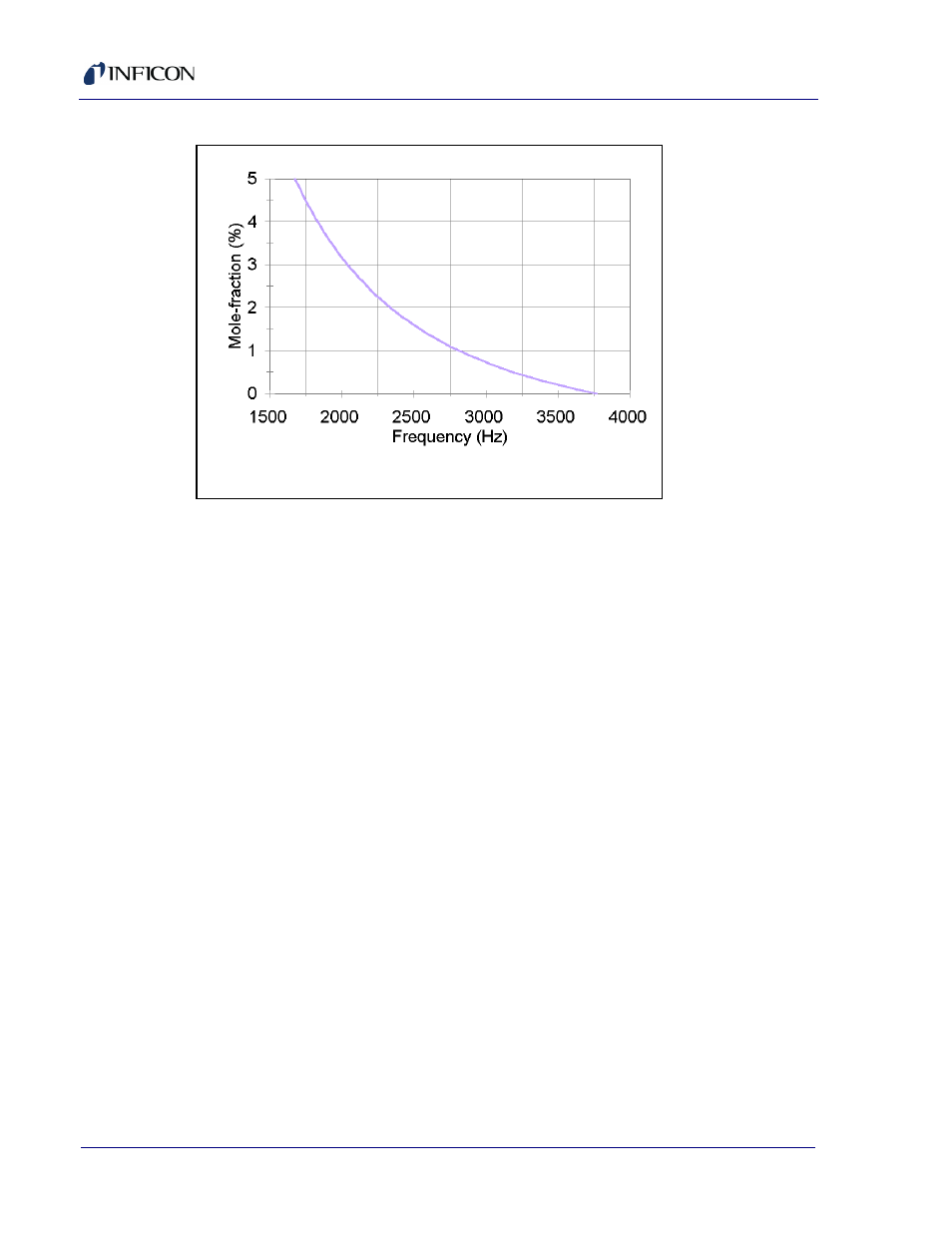

Figure 2-1 Mole Fraction of Trimethylindium in H

2

vs. Instrument’s Frequency

2.2 Measuring the Speed of Sound

A simple explanation of the functioning of this Instrument System is that it

measures concentration by first determining the resonant frequency of the gas

flowing through it and then comparing the measured resonant frequency to that

of the pure carrier gas. Utilizing this frequency ratio, , and the physical

parameters of the gasses,

and , the concentration is derived. The

instrument determines the basic resonant frequency by varying the frequency

across the operating range and then operating at the frequency where the

largest amplitude of sound is transmitted. Because the composition is

controlled, or varies slowly, and the Resonant Chamber has good acoustic

properties, the frequency may be measured with great precision. From

, the speed of sound may be derived from knowledge of the

Resonant Chamber’s length, L. In operation, the exact length is unimportant as

only the ratio of frequencies, , is used to determine concentration.

One critical issue confronted in the measurement of the speed of sound is the

ability to correctly measure or control the temperature of the gas. The

Transducer is designed to provide a user-set isothermal environment for the

gas in the Resonant Chamber and to precondition the gas as it enters the

Resonant Chamber. To aid in this preconditioning, the Transducer’s inlet tubing

is intentionally longer than is strictly necessary and is contained within the

insulation of the Transducer’s enclosure. This helps smooth the gasses’

temperature transition from the temperature of the Reactor’s supply tubing to

the Resonant Chamber’s carefully controlled temperature. There is a feedback

loop between the temperature (Controlled Variable) as measured by a PRT,

Platinum Resistance Thermometer, and the power level applied to the heaters

λ

m

γ

λ