Dakota Ultrasonics DFX-8 plus MANUAL2 User Manual

Page 58

Dakota Ultrasonics

54

Coating Probe Identified

Coating Probe Not Identified

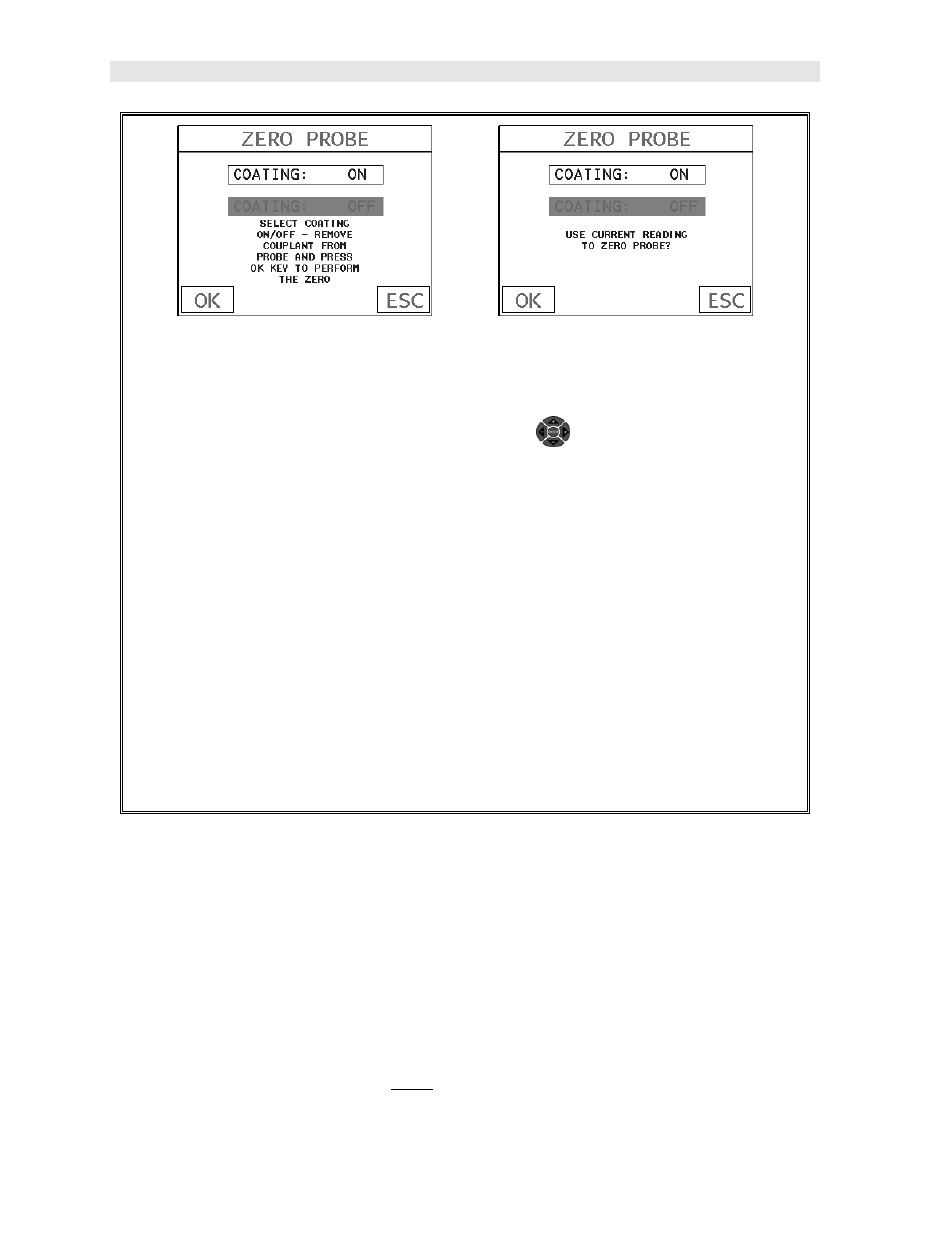

5) Press the ENTER key to display the confirmation screen.

6) If a coating transducer was identified use the

UP and DOWN arrow

keys on the left button wheel to toggle coating on/off.

7) Press the OK key to complete the probe zero function, or ESC key to cancel

the probe zero function.

8) Remove the transducer from the probe zero disk, and proceed to the

calibration section.

Note: The value that is displayed will change depending on the current velocity

setting in the DFX-8. Disregard the number that is displayed. It is not

important. What is important is accurately performing the steps outlined above

to insure reliability of the probe zero calculation.

6.3 Material Calibration

In order for the DFX-8 to make accurate measurements, it must be set to the correct

sound velocity of the material being measured. Different types of materials have

different inherent sound velocities. For example, the velocity of sound through steel

is about 0.233 inches per microsecond, versus that of aluminum, which is about

0.248 inches per microsecond. If the gauge is not set to the correct sound velocity,

all of the measurements the gauge makes will be erroneous by some fixed

percentage.

The One Point calibration is the simplest and most commonly used calibration

method - optimizing linearity over large ranges. The Two Point calibration allows for