Dakota Ultrasonics DFX-8 plus MANUAL2 User Manual

Page 47

DFX-8

Ultrasonic Thickness Gauge

43

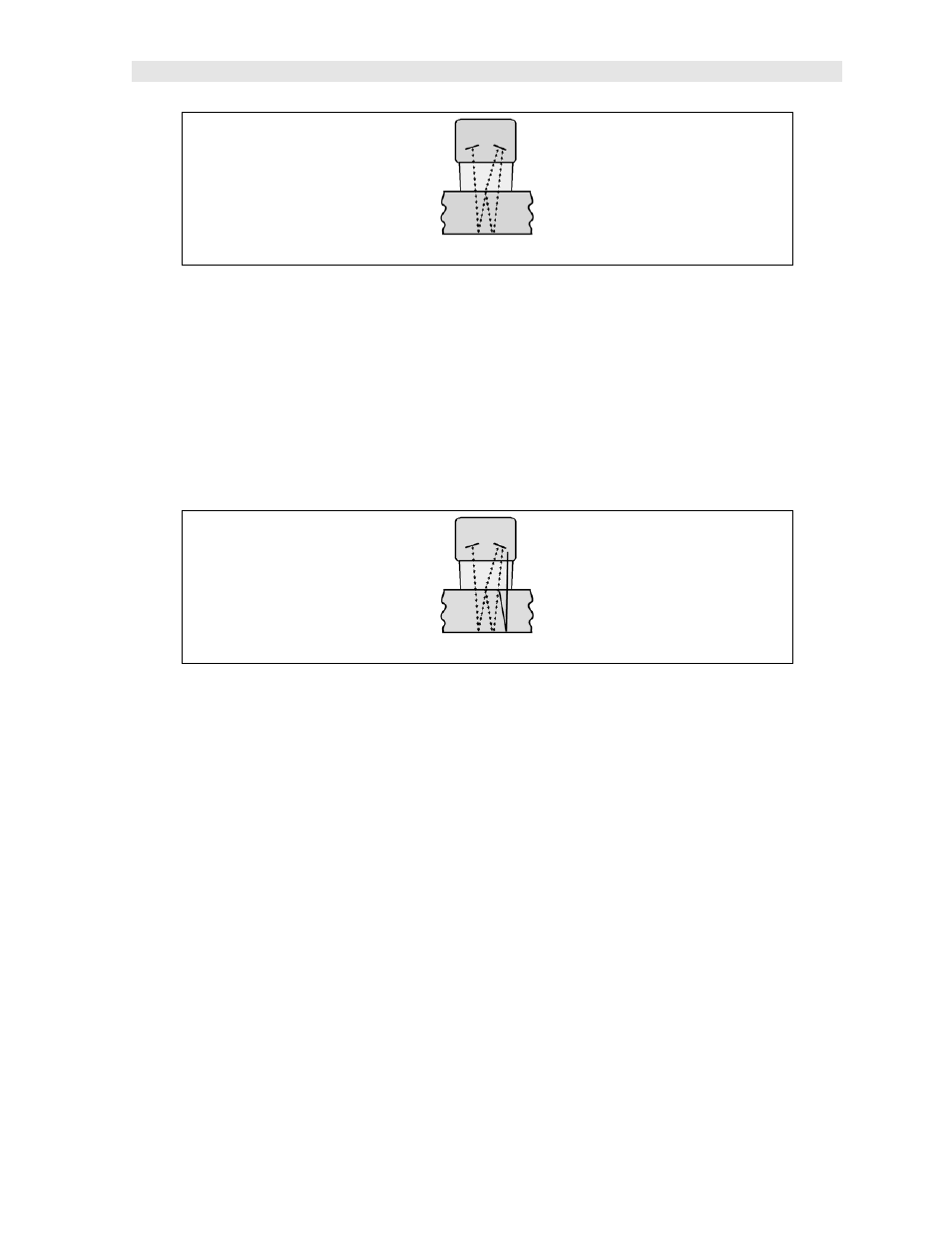

Dual Element Transducer in Echo to Echo mode

Echo-Echo Verify Mode – Thru-Verify (E-EV)

The echo-echo verify mode measures between 3 reflections. Similar to E-E mode,

this technique is commonly used to eliminate errors from surface coatings and also to

make measurements in multiple layered materials. The primary benefit of this mode,

is that a comparison is made, between the 2

nd

and 3

rd

echoes, to verify that a peak

jump has not occurred, providing an additional level of confidence to the

measurement. The disadvantage is that 3 reflections are needed which requires the

use of gates with controllable thresholds to adjust for sensitivity over a given

measurement range.

Dual Element Transducer in Echo to Echo mode

Pulse Echo Coating Mode – Coating On (PECT)

A custom hybrid combination mode using properties from the basic modes along with

a group of special techniques and theoretical wave phenomena’s to measure coating

and material thicknesses at the same time, while still retaining the ability to locate

flaws and pits in materials. Therefore, the best description for this hybrid mode is

Pulse-Echo Coating mode.

Coating Mode – Coating Only (CT)

Once again, this is a custom hybrid combination mode using special techniques to

effectively measure the thickness of coatings that are either adhered to metallic

surfaces or in standalone form. In this mode a two point calibration must be

performed. If the user will be measuring coating that has been applied to a metal

surface, the calibration must be performed using coating samples coupled to a metal

surface when calibrating. To explain further, a drop of couplant must be applied in

between the coating samples and metal surface. If the coating has not been applied

to a metal surface, the calibration should be performed accordingly.