Dakota Ultrasonics DFX-8 plus MANUAL2 User Manual

Page 22

Dakota Ultrasonics

18

8) Finally, press the MEAS key to return to the measurement screen and

begin taking readings.

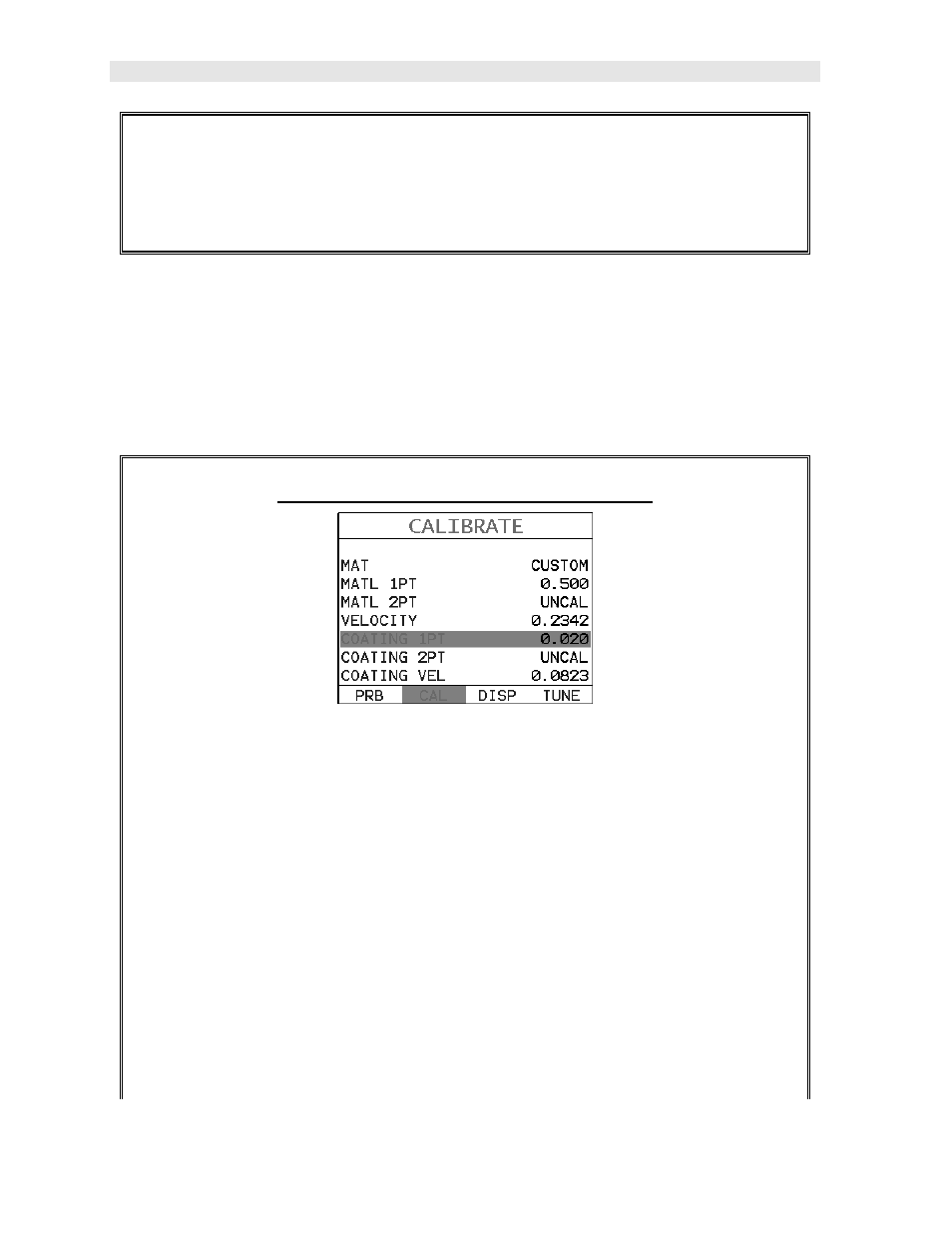

Known Coating Thickness

When the exact velocity of a coating is unknown, the user has the option of

performing a one point calibration on a sample of the coating with a known thickness

to determine the sound velocity. It would be very handy to carry a set of mechanical

calipers to use in conjunction with the DFX-8 for calibration in the field:

Using a Coating Sample to Calibrate

1) Physically measure a location on a coating sample using a set of calipers or

a digital micrometer.

Important Note: In PECT (pulse-echo coating) mode, the coating sample must

be coupled to metal in order to calibrate successfully. Simply place a drop of

couplant on a piece of metal, lay the coating sample over the couplant on the

metal and proceed to step 2.

2) Apply a drop of couplant on the transducer and place the transducer in

steady contact with the coating (on metal) sample or actual test material. Be

sure that the reading is stable and the repeatability indicator, in the top left