Dakota Ultrasonics DFX-8 plus MANUAL2 User Manual

Page 5

CHAPTER ONE

INTRODUCTION

The Dakota Ultrasonics model DFX-8 is both, an ultrasonic thickness gauge, as well

as a flaw detector. Since the DFX-8 is basically two gauges in a single package, we

split the manual into two manuals, one for each gauge type. This manual will focus

only on the thickness gauge portion of the gauge. The DFX-8 has the ability to

simultaneously measure coatings and material thicknesses while maintaining the

ability to locate pits, flaws and defects in the material. Based on the same operating

principles as SONAR, the DFX-8 is capable of measuring the thickness of various

materials with accuracy as high as

0.001 inches, or 0.01 millimeters. The

principle advantage of ultrasonic measurement over traditional methods is that

ultrasonic measurements can be performed with access to only one side of the

material being measured.

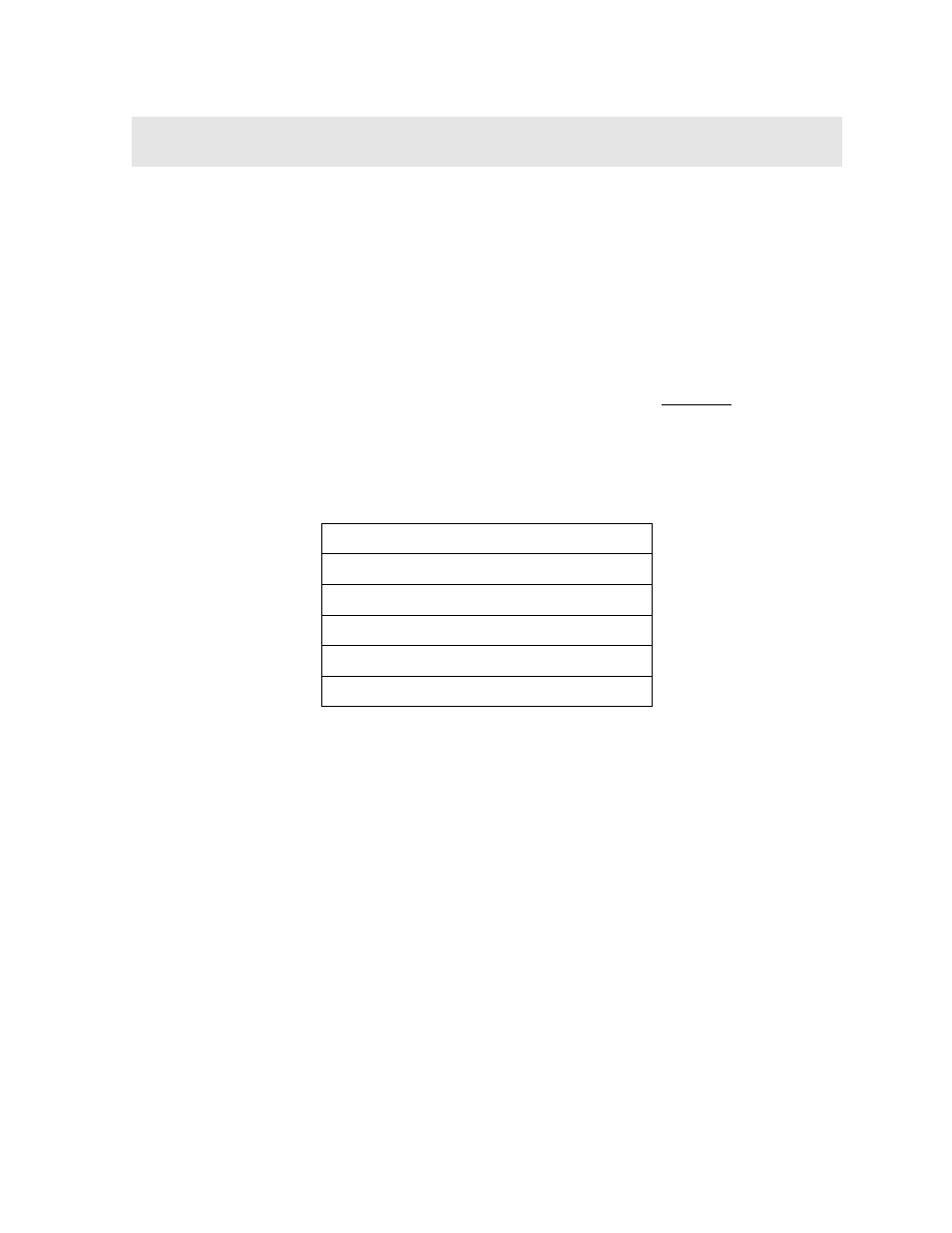

Dakota Ultrasonics maintains a customer support resource in order to assist users

with questions or difficulties not covered in this manual. Customer support may be

reached at any of the following:

Dakota Ultrasonics Corporation

1500 Green Hills Road, #107

Scotts Valley, CA 95066 USA

Telephone: (831) 431-9722

Facsimile: (831) 431-9723

www.dakotaultrasonics.com

1.1 General Disclaimer

The manual should be read and understood prior to using the DFX-8. This operating

manual provides the user with all the general information necessary to use and adjust

the designed features. However, this manual is not a certified NDT training course,

nor is it intended to be one. Training, according to company requirements, is

recommended.

Inherent in ultrasonic thickness measurement is the possibility that the instrument will

use the second rather than the first echo from the back surface of the material being

measured. This may result in a thickness reading that is TWICE what it should be.

Responsibility for proper use of the instrument and recognition of this phenomenon

rest solely with the user of the instrument. Other errors may occur from measuring

coated materials where the coating is insufficiently bonded to the material surface.

Irregular and inaccurate readings may result. Again, the user is responsible for

proper use and interpretation of the measurements acquired.